Optical brightener additives play a key role in improving the appearance and quality of plastic products. From improving whiteness in packaging to boosting visual appeal in consumer goods, these additives have become essential in many industries. In this article, we’ll dive into how optical brighteners work, their advantages, and why they’re widely used.

1. How Optical Brightener Additive Works

Optical brightener additives (OBAs) absorb UV light and re-emit it as visible blue light. This unique property makes materials appear brighter and whiter by counteracting yellow or dull tones. Optical brighteners contain organic compounds, such as stilbene, coumarin, or diphenyltriazine derivatives, effectively interacting with UV light, making the material seem more vibrant and less yellow.

This transformation process is due to a phenomenon called fluorescence. When optical brighteners are added to plastics, they modify the way light interacts with the surface, creating a more intense visual effect. The blue hue balances the yellowish tones often seen in plastic products, which is especially beneficial when manufacturers aim to produce a bright white or vibrant color. This effect remains stable over time, helping products maintain their appearance without fading or yellowing.

Optical brightener additives (OBAs)

2. Benefits of Optical Brighteners

2.1. Enhanced Brightness and Whiteness

One of the main benefits of optical brighteners is their ability to enhance the brightness and whiteness of materials. They work by absorbing UV light and re-emitting it as visible blue light, which counteracts yellow or dull tones often in plastics and other materials. This fluorescence effect gives products a striking brightness, making them appear new, clean, and fresh.

This feature is particularly advantageous in industries where a bright white appearance is essential. In textiles, for example, optical brighteners help clothing appear whiter and prevent yellowing over time; this is especially important for items such as shirts, bed linens, and towels.

The same effect can be achieved in products like household goods, toys, and packaging materials in the plastics industry. Consumers often perceive brighter, whiter items as cleaner and of higher quality, making optical brighteners essential in competitive markets where product appearance influences purchasing decisions.

Optical brightener absorb UV light

2.2. Color Enhancement

Optical brighteners don’t just improve whiteness; they also enhance the overall color vibrancy of products. Balancing the blue light emission with the material's natural colors can make colors appear more intense and saturated. This is especially beneficial in consumer goods, where color plays a significant role in product attractiveness.

In addition, manufacturers can use optical brighteners in plastics and textiles to maintain consistent color shades across multiple batches, ensuring uniformity in appearance. This color enhancement property is especially valuable in the textile industry, where consistency in color tone is crucial for brand integrity and customer satisfaction. In plastics, brighteners can be used in colored packaging materials to increase shelf appeal, adding an eye-catching visual element to the product presentation.

2.3. Reduced Need for Pigments

Optical brighteners can reduce the reliance on traditional pigments to achieve a similar effect, which can be a significant cost advantage. Generally, pigments are more expensive, and incorporating them into products to reach high brightness levels can elevate production costs. By using optical brighteners, manufacturers can achieve vibrant results while using fewer pigments.

Moreover, optical brighteners can be used in conjunction with pigments to amplify their effects, enhancing overall color vibrancy without adding excessive pigment. This is particularly beneficial for industries like packaging and consumer goods, where cost-effective solutions are essential to maintain competitiveness.

2.4. Improved Surface Quality and Clarity

Optical brighteners can also improve the surface quality and clarity of materials, making products look smoother and more polished. In transparent or translucent plastic products, optical brighteners improve clarity, providing a clearer and crisper visual experience.

For example, in PET water bottles, optical brighteners can give the plastic a pristine, crystal-clear appearance that conveys a sense of purity and quality to consumers. Similarly, in plastic films and packaging materials, these brighteners enhance transparency and surface smoothness, making the products appear more premium and refined.

2.5. Cost-Effectiveness

For manufacturers, optical brighteners are a cost-effective solution for enhancing the visual appeal and quality of products. Compared to other options, such as adding additional pigments or coatings, optical brighteners offer a more affordable alternative that delivers similar results. The cost savings can be especially significant for companies producing large volumes of products.

By using optical brighteners, manufacturers can produce brighter, more attractive products without significantly increasing production costs. This cost-effectiveness makes optical brighteners an attractive option for businesses aiming to improve product quality without inflating budgets.

Optical brighteners are a cost-effective solution

3. Common Applications of Optical Brightener Additives

3.1. The optical brightener can be used as a marker in medicine

Using the difference of affinity and ability of optical brightener to different cells, it can be used as a marker in medicine to detect the existence of special protein or antibody in cells, and it can be used in medical diagnosis. A rapid and reliable diagnosis of fungi and algae can be made by treating tissue sections of tested animals or humans with a fluorescent whitening agent containing at least four sulfonic groups of stilbene, followed by a fluorescence microscope test.

3.2. Optical brightener can improve the appearance of industrial liquids

Fluorescent brighteners are used in industrial liquids to improve the appearance of products. For example, after the optical brightener OB is dissolved in organic solvents, it can be mixed in waxes, paraffins and mineral and vegetable oils, the light yellow inherent in these products can be effectively masked by the use of a small amount of this fluorescent whitening agent. Because fluorescent brightener OB has good light resistance in organic solvents, it can be added to a large number of industrial liquids.

3.3. Optical brighteners can be used for stationery and magnetic boards

Fluorescent brighteners are used as a component in magnetic writing board emulsions, which are sealed in a PVC mesh to form emulsion lattices with iron powder added. The writing board is made of smooth lines and clear black and white.

3.4. Optical brightener can be used as UV absorbers

The ability of the fluorescent whitening agent to absorb ultraviolet light is used in the etching process of the integrated circuit board and in the hair care composition to reduce the harm of ultraviolet light to the hair.

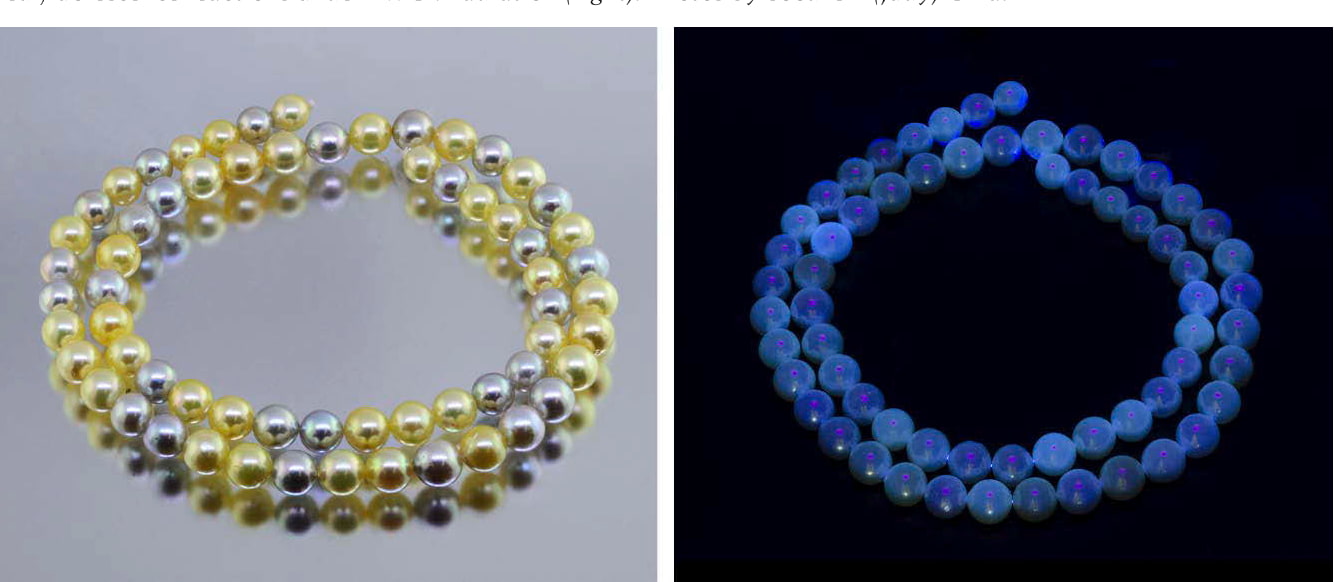

3.5. Optical brightener can be used for pearl whitening

The Pearl is taken out from the shell and sold on the counter, which needs a series of processes such as pretreatment, bleaching, whitening and glazing to make the color and luster more pleasing to the eye. Among them, the pretreatment is to expand the pearl with benzene and ammonia water, then dehydrate it with ethanol or glycerin, then bleach it with hydrogen peroxide or chlorine to make the pearl surface whiter, on this basis and then use fluorescent whitening agent for whitening treatment, together with the final polishing, so that the white pearl becomes whiter.

Optical brightener can be used for pearl whitening

3.6. Optical brightener for plastic

In plastics manufacturing, optical brighteners play a crucial role in enhancing the appearance of final products. When added to plastic compounds, these additives absorb invisible UV light and re-emit it as visible blue light, resulting in a brighter and cleaner appearance. This effect is especially beneficial for products where a high level of whiteness or vibrancy is desired, such as in consumer goods packaging, automotive parts, and home appliances. Optical brighteners also improve consistency in color, counteracting yellowing that can occur during production, and help extend the life and visual appeal of plastic items used in everyday applications.

Optical brightener for plastic

4. Conclusion

Optical brightener additives are an essential tool in modern manufacturing, enabling companies to produce high-quality and visually appealing plastic products. These additives enhance brightness, counteract yellowing, and improve the overall appearance of products, making them a popular choice across various industries. Their applications are vast, ranging from packaging and household items to automotive parts and electronics. By incorporating optical brighteners, manufacturers can boost consumer appeal and ensure their products stand out in a competitive marketplace.

5. About EuroPlas’ Optical Brightener Additive

EuroPlas’ Optical Brightener Additive enhances the whiteness and brightness of various plastic resins, including PE, PP, ABS, PET, and PA. This additive improves light reflectivity, ensuring that end-products meet aesthetic standards with a polished, vibrant look.

EuroPlas’ Optical Brightener Additive

EuroPlas’ optical brightener is ideal for applications like blow-molded items, raffia, non-wovens, HDPE bottles, and injection-molded products. With certifications for quality and specifications tailored for optimal performance, EuroPlas ensures that storage and transportation are handled precisely. For clients, this means a reliable, high-quality solution to achieve visually appealing, durable plastic products across multiple industries.

For more information and samples, please contact us HERE!