PLA Plus vs. PLA: Comparing These Two Plastics

Sustainability in recent years led to bioplastics and leading this is Polylactic Acid, also known as PLA. Of its variants is PLA Plus which has improved making it have some reputation. This article aims to understand which kind of PLA is better between PLA Plus vs. PLA.

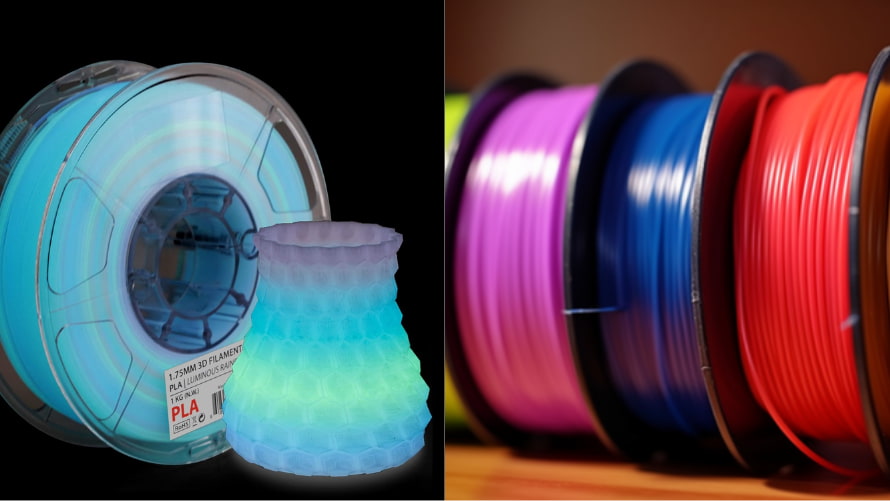

1. Overview of PLA and Its Variations

Polyactide Acid (PLA) is a biodegradable thermoplastic synthesized from renewable resources such as corn starch or sugarcane. This material has become very popular since it reduces the impacts on the environment and since it can be used in multiple products.

Key Variations of PLA:

- Standard PLA: This is the most preferred type of PLA due to its versatility, and it gives good prints easily and quickly. Such use makes it suitable for use in applications like 3D printing, packaging, and in products that are disposable. Nevertheless, standard PLA tends to be brittle and has low thermal stability which makes it unsuitable for use in functional parts.

- PLA Plus: PLA Plus has been developed to promote improved mechanical properties, durability and heat stability. It solves the main problem of the traditional PLA and brings new potential for its application, such as functional models and limited production parts.

- Specialty PLAs: PLA at the same time has various other formulations, for example, those wherein it is combined with other materials in order to improve specific characteristics. Additives such as colors, change in fillers to enhance the rigidity, or in the flexibility of the material.

Read more:

PLA Plus is designed to improve the mechanical properties.

2. Comparison of PLA Plus vs. PLA

The main properties and cost of PLA Plus vs. PLA are discussed here. Before going into detail, here is a short table comparing these two popular materials:

| |

PLA |

PLA Plus |

| Strength and durability |

Reasonably strong but brittle |

Enhanced tensile strength and impact resistance |

| Heat resistance |

Up to 60°C (140°F) |

70°C (158°F) |

| Flexibility |

Rigid and brittle |

More flexible, reducing the risk of breakage |

| Biodegradability |

Fully biodegradable under industrial composting conditions |

Also biodegradable, but may take longer depending on additives |

| Ease of printing |

Very user-friendly; minimal adjustments needed |

Easy, but may require slight adjustments |

| Cost |

Generally more affordable |

Slightly more expensive due to enhanced properties |

2.1. Comparison in strength and durability of PLA Plus vs. PLA

- PLA Plus: Exhibits improved tensile strength and resistance to impacts, reducing the possibility of breaking or shattering while in use. This adds to the durability of PLA Plus, allowing it to serve in functional parts and products that demand much more resilience.

- PLA: PLA is normally strong enough for most purposes, but it tends to be a bit brittle and may crack under stress.

When comparing PLA Plus vs. PLA, PLA Plus tends to be more durable.

2.2. Comparison in heat resistance of PLA Plus vs. PLA

- PLA Plus: Higher temperature resistance; its HDT is usually above 70°C or 158°F. Thus, PLA Plus is perfectly suitable for items that would be exposed to warmth, such as kitchenware or outdoor products.

- PLA: Low heat resistance, about 60°C or 140°F deforms at higher temperatures; hence, their uses are limited.

2.3. Comparison in flexibility of PLA Plus vs. PLA

- PLA Plus: More flexible than the PLA, hence reducing the chances of breakage in functional parts. This makes PLA Plus ideal for parts that have to withstand a certain amount of stress or bending without breaking.

- PLA: In general, standard PLA is rigid, hence brittle and likely to fail in an application needing some flexibility. The rigidity of PLA may limit its application for a product that needs to sustain bending or impact.

2.4. Comparison in biodegradability of PLA Plus vs. PLA

- PLA Plus: PLA Plus, though biodegradable, probably has some additives that influence the time it takes for it to break down completely. It may take much longer to decompose compared to the usual PLA, depending on the used formulation.

- PLA: Biodegradability is one of the main selling points of PLA. It can degrade into its full form under the conditions of industrial composting. Therefore, PLA would be an environmentally friendly product to reduce environmental impact.

Between PLA Plus vs. PLA, it may take much longer to decompose in PLA Plus.

2.5. Comparison in ease of printing of PLA Plus vs. PLA

- PLA Plus: Despite still being relatively easy to print, PLA Plus might necessitate slight adjustments in printing settings-such things as temperature and speed. Printing performance may also benefit from the inclusion of a heated bed.

- PLA: With its ease of printing, regular PLA is a favorite among makers for its minimal warping and great adhesion on the print beds. It usually requires very little tweaking for printing.

2.6. Comparison in cost of PLA Plus vs. PLA

- PLA Plus: It is more expensive, generally speaking, because of its upgraded properties, but sometimes the extra investment is well worth it for an application that needs better performance.

- PLA: Generally cheaper, thus, is attractive for hobbyists and people with projects that have a stringent budget.

3. Applications of PLA Plus vs. PLA

Understanding the specific applications of PLA vs. PLA Plus is essential to achieve optimal results in your projects. Here are applications of PLA Plus vs. PLA:

3.1. Applications of PLA Plus

- Mechanical parts: PLA Plus can be used in a variety of mechanical parts, including gears and brackets, because of its toughness. Due to its resistance to impact, it works reliably under harsh conditions.

- Automotive parts: PLA Plus is used in the automotive industry to create lightweight interior parts. The strength of PLA Plus leads to efficiency in vehicles that help in environmental sustainability.

- Consumer electronics: PLA Plus finds its application in making the housing and casing of different consumer electronics. Its resistance from impacts protects the components and offers an environmentally friendly ability.

- Sporting goods: Sporting goods use PLA Plus in the production of durable equipment and accessories. It offers reliable means to athletes in performance and manufacturing that is friendly to the environment.

PLA Plus Brackets

3.2. Applications of PLA

- Prototyping 3D printing: PLA is one of the most usable and high-quality processes in 3D printing. It enables the making of very detailed prototypes and decorative items since it features low-warping and vibrant color options.

- Food packaging: PLA finds extensive application in food packaging, such as cups and containers that are disposable in nature. Its biodegradable property acts as an added positive; these materials also meet the basic norms of food safety.

- Consumer goods: PLA is put to versatile use in toy lines, home decor items, and fashion accessories.

- Medical appliances: PLA in medical applications includes disposable surgical instruments and the packaging of medical devices. Biodegradable and non-toxic, it contributes to less waste without sacrificing hygiene.

PLA toys

4. Which Plastic Should You Choose?

As in the case of choosing PLA Plus vs. PLA for projects, it all comes down to the needs and specifications of the application. Both are ideal for use under different conditions due to their distinctive properties and hence require the need to understand these very differences that could get you the perfect choice.

PLA Plus offers enhanced strength, durability, and resistance to environmental factors, making it a better option for functional parts and applications that require greater resilience. Its improved mechanical properties allow for the production of items that can withstand stress and exposure to the elements, making it suitable for both indoor and outdoor use.

On the other hand, PLA is an easy printing material with excellent quality prints and good color, mainly targeted for beginners and to produce artistic pieces and some non-functional prototypes. Since PLA is biodegradable, environmentally sensitive users also use PLA to develop their models in a friendlier manner.

5. Conclusion

PLA Plus vs. PLA have their unique advantages. By carefully considering these aspects, you can ensure that your final product not only meets your expectations but also performs effectively in its intended application.

6. About EuroPlas’ Bioplastics

EuroPlas is a leading manufacturer of plastic additives and compounds in Vietnam, committed to delivering high-quality, environmentally friendly solutions.

Our bioplastic compound, BiONext, serves as sustainable alternatives to traditional plastics, made from renewable sources like polylactic acid (PLA) and polyhydroxyalkanoate (PHA).

Contact us now for more details!