PLA vs. PETG: What Are The Differences?

PLA vs PETG is one of the material lines that is mentioned with high frequency in many manufacturing industries today. The following article will provide a close-up view of the properties of these two material lines. Besides, it will evaluate the pros & cons in the most detailed way about PLA vs PETG. Decisions in choosing upcoming materials will be optimized in a wonderful way right after the article below!

1. Overview Of PLA And PETG Plastic

Both PLA vs PETG are considered environmentally friendly materials

PLA vs PETG are two favored plastics thanks to their impressive performance and environmental friendliness.

PLA plastic, also known as Polylactic Acid. They are a biodegradable plastic derived from renewable resources such as corn starch or sugarcane. Currently, PLA is widely used in packaging applications and disposable items because they are environmentally friendly. In terms of properties, PLA has a low melting point and is known to be more brittle than other types of plastic. In particular, they are a type of plastic that can be decomposed under industrial conditions, so they are suitable for large-scale production.

PETG plastic, also known as Polyethylene Terephthalate Glycol. They are known as one of the thermoplastic lines. In fact, PETG is also a type of plastic that is widely used in many areas of life. They possess good durability, flexibility and impact resistance. Although PETG is not biodegradable like PLA, it can be completely recycled, so it is also considered an environmentally friendly material line.

Read more: How Is PLA Plastic Made?

Read more: PCTG vs. PETG Plastic: What Are The Differences?

2. PLA vs. PETG: Comparing Properties

PLA vs PETG are considered two types of plastic that are very popular in many fields today thanks to their excellent properties. Let's analyze in more detail and the impressive properties they possess right below:

2.1. Environmental friendliness

One of the great properties that both PLA vs PETG are highly appreciated for is their environmental friendliness. PLA is made from renewable resources such as corn starch and sugarcane, so they can be biodegradable under industrial composting conditions. As for PETG, although they are not biodegradable, they can be reused and recycled through a number of other treatment methods.

In general, PLA vs PETG can be considered one of our advanced and environmentally friendly materials in minimizing most of our annual waste.

2.2. Durability

Durability is one of the factors that is very important when comparing PLA vs PETG. In particular, PETG is considered to be more durable, impact resistant and less brittle than PLA. For PLA, this material line is quite brittle and can break or crack when subjected to strong impact.

In general, it can be seen that PETG has a clear advantage in terms of durability. They are preferred when choosing to produce products that require hardness and durability such as product protective packaging or some technical protective layers.

PLA vs PETG are considered two types of plastic that are very popular in many fields today thanks to their excellent properties

2.3. Heat resistance

This property will help determine which PLA vs PETG has the advantage when operating in extreme temperature environments. For PLA, they have a relatively low melting point of around 180-220°C. Notably, PLA will tend to deform or weaken at temperatures above 60°C. In contrast, PETG possesses a slightly superior heat resistance. PETG may experience deformation or weakening when exposed to temperatures of around 80-90°C.

Therefore, it can be said that PETG is a better choice for products exposed to higher temperatures. They may be superior to PLA in applications that require heat resistance such as household products and some machine protection covers.

2.4. Flexibility

This property will determine the ease of manufacturing and processing between PLA vs PETG. It can be said that PETG is less brittle and more flexible. They can easily undergo bending manufacturing processes with a very limited rate of cracking. On the other hand, due to its stiffness, PLA will tend to break easily under bending stress.

In short, for applications that frequently exhibit bending or folding, PETG should be preferred. They are ideal for functional parts that require a high degree of flexibility or high frequency of flexing.

2.5. Chemical Resistance

This ability helps determine the performance in harsh environments between PLA vs PETG. PETG is resistant to a wide range of chemicals, including acids, alkalis, and oils. On the other hand, PLA is more sensitive to chemicals and can degrade or weaken when exposed to certain substances.

From this, it can be concluded that PETG becomes a better choice for applications that require exposure to chemicals or solvents. They can be used in industrial applications or in harsher chemical environments than PLA.

3. PLA vs. PETG: Pros & Cons3. PLA vs. PETG: Pros & Cons

When comparing PLA vs PETG, it can be assessed that PLA is generally cheaper than PETG filaments

| PLA vs PETG |

Pros |

Cons |

| PLA |

Biodegradability: PLA is biodegradable into natural components under industrial composting conditions. They are an excellent choice for manufacturing short-term products, such as packaging and disposables, without creating environmental concerns.

Renewable: PLA is derived from renewable resources such as corn starch or sugarcane, rather than petroleum. Being made from plant sources without the need for fossil fuels reduces carbon emissions into the natural environment.

Easy to print: PLA is widely considered one of the easiest materials to 3D print. The reason why it is suitable for 3D printing is because it possesses properties such as a low melting point, good adhesion to the print bed, and the ability to produce smoother and more precise prints.

Safe for human health: PLA is considered non-toxic and safe for applications directly related to human health. The reason is that they do not emit toxic fumes when printed or heated. This makes them an ideal choice for applications containing food and medical devices.

Cost-effective: When comparing PLA vs PETG, it can be assessed that PLA is generally cheaper than PETG filaments. The affordable price and ease of use make PLA a popular choice in many industries and educational modeling projects.

|

Brittleness: When comparing PLA vs PETG, it has been shown that PLA is more brittle than PETG. They are prone to cracking or breaking easily when subjected to strong force or impact from the external environment.

Limited chemical resistance: Since PLA is biodegradable, it is very limited when operating in environments such as solvents, oils and acids.

|

| PETG |

Recyclability: PETG is honored to be a line of materials that can be reused or recycled. This is to contribute to reducing the amount of waste released into the environment.

Durability: When comparing PLA vs PETG, PETG is known for its superior durability and impact resistance compared to PLA. They can withstand more physical stress without cracking or breaking.

Heat resistance: Between PLA vs PETG, PETG has a higher heat resistance than PLA. They have an advantage in products that are exposed to heat such as food containers, mechanical parts and some other applications.

Flexibility: As mentioned above, PETG is highly flexible and can bend under pressure without breaking. They perform well in positions that require resilience or handle some mechanical movements such as hinges, product covers etc.

Chemical resistance: PETG is highly resistant to a wide range of chemicals as mentioned. This excellent ability makes them dominant in applications that require durable performance in harsh environments.

Aesthetics: Due to its excellent transparency, PETG has a greater aesthetic appeal especially in packaging applications. It can also be easily colored while maintaining a smooth, glossy appearance. This is a huge advantage in creative and commercial applications.

|

Not biodegradable: PETG is not biodegradable like PLA. They need to be recycled in other ways such as reuse or melting.

Lower stiffness: When comparing PLA vs PETG it can be seen that PETG has a slightly lower stiffness than PLA. So sometimes they will not be able to provide the structural stiffness required for certain designs. |

4. PLA vs. PETG: Comparing Applications

Thanks to their excellent properties, both PLA vs PETG are favored by consumers. Both materials are considered extremely popular in many areas of life today. Let's take a look at some typical applications of PLA and PETG below:

4.1. PLA applications

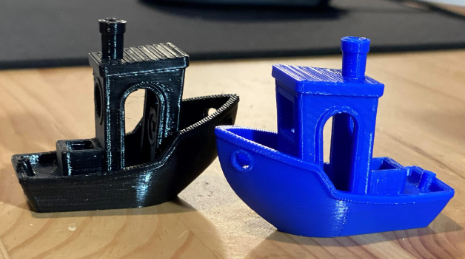

3D printed products made from PLA plastic always bring perfection in printing surface and accurate proportions

3D printing products: Considered one of the materials with excellent compatibility for the 3D printing process. They are easy to create product models in fields such as engineering, architecture and design from basic to sophisticated. 3D printed products made from PLA plastic always bring perfection in printing surface and accurate proportions.

Product packaging: Thanks to PLA's biodegradability, it becomes an ideal choice for products such as cosmetic packaging, food packaging, food containers, etc. These products always have the advantage of sustainability in production without worrying about environmental issues. In addition, they are also considered safe for human health.

Medical devices and implants: Typical products that PLA has contributed to the medical industry include biodegradable sutures, implants, and some devices in the drug delivery system into the human body. The strength of this material is its biocompatibility and ability to safely decompose in the body without causing harm or requiring disposal.

Disposable products: PLA is chosen to produce disposable household items such as knives, scissors, eating utensils and trays. They are considered a sustainable alternative to traditional plastic cutlery because they possess good hardness and are also naturally biodegradable in industrial composting facilities.

Production of learning tools: This material is a great solution for educational institutions in creating a variety of 3D printed objects such as learning tools and research models. They offer aesthetic appeal and cost benefits for many educational settings

4.2. PETG applications

PETG contribute to the production of items such as bottles, jars, food containers and snack packaging

Mechanical Industry: PETG is used to create functional parts such as gears, racks and machine components. These products will have excellent durability and impact resistance when operating in harsh environments.

Medical equipment and packaging: Some of the applications of PETG in this field include pharmaceutical packaging, surgical trays, medical tubes and some transparent containers. They provide the ability to be sterilized without losing the integrity of the object it contains.

Food and beverage containers: They possess the outstanding chemical resistance of PETG that they can bring to humans a safe product. They contribute to the production of items that have a direct impact on human health such as bottles, jars, food containers and snack packaging.

Display tools: Known for its transparency, PETG is popular in product display applications. They provide a high level of aesthetics, a sleek and professional look to the products they contain. Common applications include cabinets, display trays, sales racks, etc.

Outdoor Equipment Covers: They perform well as protective covers, weatherproof covers, and some outdoor signs. They help ensure that these devices will maintain their durability when exposed to harsh outdoor weather elements.

5. Which Plastic Should You Choose?

To make a more accurate choice between PLA vs PETG, it is necessary to consider to chemical environment where they operate

Based on the properties and strengths analyzed above, it can be seen that PLA vs PETG are both extremely potential materials for your upcoming production plan. In particular, to make a more accurate choice between PLA vs PETG, it is necessary to consider factors such as chemical environment, requirements for hardness, flexibility or temperature at which the equipment will operate. This helps to provide a more detailed perspective to decide on the most optimal material.

6. Conclusion

In conclusion, PLA vs PETG are two material lines that bring many benefits to many industries thanks to their properties. In particular, both PLA vs PETG are considered environmentally friendly materials. In particular, PLA possesses biodegradability while PETG has flexible recycling capabilities. Both material lines bring certain advantages to the manufacturing industry. Understanding the properties, benefits and common applications of PLA vs PETG will be very helpful in optimizing the production process.

7. About EuroPlas

EuroPlas is proud to be one of the most reputable and trustworthy material suppliers worldwide. You can easily find and buy bio-filler, color masterbatch, plastic additives, engineering plastic compounds, and bioplastic compounds, etc., with just a click of the mouse. Besides, come to EuroPlas' blog today to update more useful materials information. We are a provider of optimal material solutions with a series of high quality plastic lines. Our solutions meet the diverse needs of the world's industries, not only in terms of high standards and reliability but also in terms of environmental obligations.