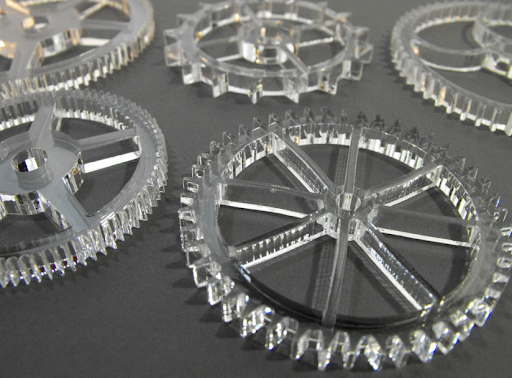

Plastic gear supports the turning process of the machine more smoothly and flexibly

Plastic gear is one of the extremely optimal driving tools in a variety of machinery devices. They operate based on the movement and interaction of a gear set (usually linked by a belt or chain). The benefits of plastic gear includes helping to increase speed, decrease speed, and adjust speed flexibly. In addition, plastic gear also supports the turning process of the machine more smoothly and flexibly. The following will be extremely interesting information about plastic gear in each specific field. Understanding the properties of plastic gear will help optimize costs for your upcoming project!

1. Four applications of plastic gear

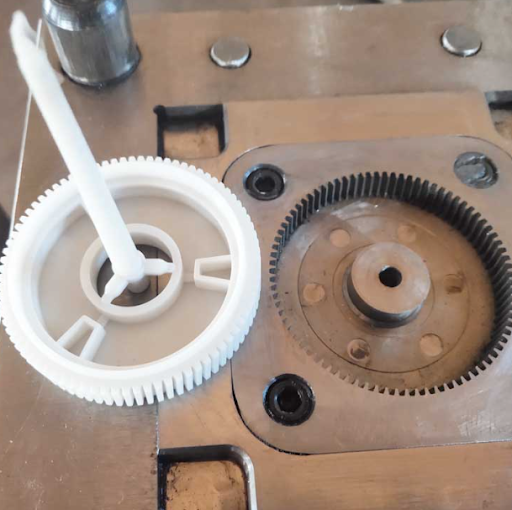

Plastic gear is an essential part of the gearbox, which is considered the most important component in a car

Plastic gear is considered one of the extremely essential parts in the operation of a car. Specifically, plastic gears are an indispensable part of some parts such as windshield wipers, HVAC (heating, ventilation, air conditioning), and car windows, which are considered extremely important parts in cars. . The operation of plastic gear is the transmission process that helps car parts operate more smoothly and easily. It can also be understood that plastic gear helps the driver better control the car's functions during travel.

Regarding design: depending on the needs and driving conditions and the vehicle manufacturer's design, the gear design will include from 3 to 6 gear sets accompanying the gear transmission. Their general design is that gear sets are surrounded by belts or chains that create transmission links between odd gears.

About the benefits: plastic gear brings outstanding innovation in the automotive technology industry. Weighing less than most other metal devices, plastic gear contributes to fuel economy during vehicle transmission. On the other hand, plastic is one of the materials that is highly appreciated for its flexibility in the production process. They can be suitable for many manufacturing methods such as extrusion, injection molding, blow molding, etc. This makes them flexible and adaptable to many designs from basic to complex.

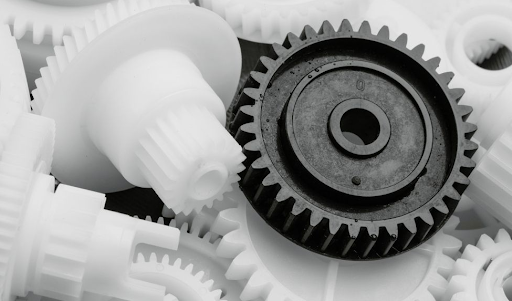

Some machinery require gear include blenders, mixers, bicycles, production lines, agricultural machinery etc

Plastic gear brings outstanding benefits in the operation of a variety of machines. They are not only helpful in the field of automotive technology but are also one of the useful tools in production equipment and life. Some machinery applications that require gear include blenders, mixers, bicycles, production lines, agricultural machinery and some lines of water supply machinery.

In terms of design, plastic gear is considered a machine with a simple design but extremely surprising performance. Depending on the type of machine, there are different numbers of gear, sizes and shapes. They are usually connected together by belt loops or chains. The gear will be carefully arranged and calculated to provide smooth operation.

In principle, gear will be used as a group in the machine to improve the performance of the machine. During movement, they will drive the machine to operate. Power from the crankshaft (the rotating shaft that takes energy from the engine) is transmitted from one gear to another, creating movement in the machine.

In terms of benefits, in the transmission process with plastic gear, they can bring results such as increased speed, increased force, change of direction, etc. These methods can operate based on a variety of different principles. Typical of them are adjusting the number of gears, size and shape of plastic gear. They will produce the expected results.

Plastic gear contribute to the transmission process, deceleration, changing the direction of rotation of the robot

Plastic gear is one of the main parts of the robot's smooth operation. In robots, plastic gear contributes to the transmission process, deceleration, changing the direction of rotation of the robot, etc. They contribute to connecting robot parts and help them operate more smoothly and flexibly.

In terms of design and operation, most plastic gear designs in robots will be extremely diverse depending on the size and task of the robot. Plastic gear is designed as mechanical parts. They are often surface-polished to meet the needs of quietness, precision, aesthetics and high safety. Similar to other applications, plastic gear in robots also operate based on the principles of transmission from the teeth of the gear. However, the difference in robots is that they have higher requirements for smoothness when operating and aesthetic needs also need to be emphasized.

Some types of plastic gear commonly used in robots include cylindrical gear, helical gear, bevel gear, internal gear, worm gear, etc. Among them, helical gear is used when quietness and high durability are needed. Worm gear is used in joints that assist in opening and closing robot hand grippers, etc.

Plastic gear contribute to a variety of medical examination and treatment processes, even testing and research processes

Plastic gear is considered an indispensable tool in medical technology. Unlike other applications, plastic gear used in medicine always has stricter and stricter requirements. Plastic gear needs to ensure safety conditions, antibacterial standards, and comply with regulations and specifications for each application. Plastic gear contributes to a variety of medical examination and treatment processes, even testing and research processes.

The benefits of plastic gear in medicine are considered to be extremely great. Specific applications include positioning devices, X-ray and ultrasound scanners, examination tables, surgical robots, OP tables or hospital beds. In addition, plastic gear also assists in making connections between joints in rehabilitation equipment and health care equipment. They help optimize treatments and treatments as well as provide greater comfort for patients and medical staff alike.

Unlike other applications, plastic gear needs to meet higher safety requirements when used in a medical environment. Plastic gear needs to have an emergency stopping torque of up to 500%, extremely high precision, good resistance to breakage and cracking, safe for human health, good antibacterial and continuous operation for a long time. In particular, plastic gear needs to be tested for safety criteria and measure the accuracy of technical parameters carefully and strictly.

Plastic gear offers manufacturers a variety of options in terms of production methods from injection molding, extrusion molding, blow molding, etc.

Plastic gear are increasingly popular thanks to their versatility and countless benefits for both manufacturers and consumers. The benefits that plastic gear bring can be listed as follows:

Light weight: plastic gear are many times lighter than metal. Designing equipment with plastic materials can help machines reduce weight and operate more gently. This also contributes to helping the device save significantly on fuel consumption.

Easy to shape: plastic is inherently one of the most flexible materials in the production and shaping process. Plastic gear offers manufacturers a variety of options in terms of production methods from injection molding, extrusion molding, blow molding, etc. In addition, plastic gear are suitable for all designs from basic to elaborate thanks to their easy shaping ability. Plastic gear can be flexible in adjusting size, color, shape etc.

Super durable: plastic gear will bring incredible performance to the product thanks to their durability. Plastic gear possess properties such as high hardness, good antibacterial, impact resistance, wear resistance, and good heat resistance. Plastic gear helps machines operate well in harsh environments while largely minimizing rust and cracking.

Low Noise: Plastic gears provide the operating system with a special noise reduction advantage. Plastic gears not only help the device operate smoothly but also limit noise during operation.

Low Cost: Plastic gears provide investors and consumers with an optimal cost solution. Thanks to the extremely reasonable cost of materials, the price of plastic gears on the market is not too expensive. In addition, this material adapts well to a variety of production methods, so it is of great help to investors.

Corrosion Resistance: Plastic gears are durable and meet the needs of operating in harsh environments thanks to their excellent corrosion resistance. This is also the reason that plastic gears are one of the ideal choices for outdoor equipment and many machines operating in highly corrosive environments.

Read more: Here Are 3 Types Of Plastic Fitted For Plastic gear

3. Conclusion

In conclusion, plastic gear is one of the ideal choices to improve product performance in a variety of fields. Many fields have successfully applied plastic gear such as automobile technology, machinery, robotics and medicine, etc. Each application will have its own needs in terms of materials as well as the design of plastic gear to ensure proper operation. Plastic gear are always the top choice because they are both durable, lightweight and easy to design.

4. About EuroPlas

You can easily find and buy bio-filler, color masterbatch, plastic additives, engineering plastic compounds, and bioplastic compounds, etc. by contacting EuroPlas immediately!. We are proud to be a provider of optimal material solutions with a series of high quality plastic lines. Our solutions meet the diverse needs of the world's industries, not only in terms of high standards and reliability but also in terms of environmental obligations.