Nowadays, it's common to see plastic in construction. The material plays a more significant role in this industry than you thought. It's an essential source for various applications, from indoor ones, such as doors and windows, to internal details, such as cables and floor coverings.

However, not all plastics are suitable for these applications due to different properties and advantages. Let's follow along to find out more about plastic materials in construction in the article below!

Read more: What is plastic? Everything you need to know about plastic

1. Why should you choose plastics in construction?

There are reasons for plastics to be present in many construction applications. They are:

- Durable: Plastics are tougher and more durable than their material counterparts. Plastic hardware is weather and corrosion-resistant, prolonging the lifespan of the final products and their usability.

- Lightweight: Plastics usually weigh less than metals and are easy to install and design.

- Cost efficiency: Saving production costs is always one of the priorities of businesses. Plastics are more economical than metals and wood, making them an ideal option in many construction applications.

- Energy-saving and recyclable: Plastics use less heat, contributing to energy saving. Plus, one great thing about this material is it can be recycled. You can reuse it without compromising its chemical properties.

- Safe and easy to use: Metals are usually heavy and can cause injuries while moving. However, you can carry or fit plastics in different desired spots as they are light and easy to handle.

2. Common types of plastic materials in construction

Here are some common types of plastics in construction:

Here are some common types of plastics in construction:

2.1. Acrylic

Acrylic offers great optical clarity, scratch resistance, and rigidity. Therefore, it's ideal for transparent sheeting applications, such as windows or LCD screens. Besides, it's also the material in less obvious products, including concrete coating, paint, and sinks.

2.2. Composites

Composites consist of 2 or more constituent materials. The combination's purpose is to enhance each material's strength and eliminate its weaknesses. For example, FRP (fiber-reinforced polymer) is a perfect alternative for metallic materials in applications that call for excellent load-bearing strength.

2.3. PVC or Polyvinyl Chloride

PVC is one of the common plastic materials in construction since it's durable and inexpensive. It acts as a building material used in flooring, roof membranes, pipes and fittings, and window and door profiles.

2.4. Polypropylene

Polypropylene is another ideal building material, especially in most applications requiring heat, fatigue, or shatter resistance. It's often used in piping systems, carpeting, electrical cable insulation, and plastic machine parts.

2.5. Polycarbonate

Polycarbonate has similar physical properties as acrylic, including transparency and high impact resistance. Thus, it's suitable for applications with high requirements of clarity and strength, such as noise barriers, security glazing, or safety eyewear. Besides, you can use it several times after its first life, thus benefiting the environment.

3. How is plastic used in construction?

3.1. Roofing

3.1. Roofing

One of the most popular applications of plastics in buildings is roofing. The roof is usually made of 2 plastic layers. The upper part is thermoplastic olefin or vinyl, and the lower one is polyurethane foam. The materials consume less heat, protect the roof from damage, and keep the house's interiors cool.

3.2. Flooring

PVC and polyethylene are the two most suitable candidates for flooring as they have excellent wear and tear resistance ability. Besides, they also can reduce the sound pollution level and are easy to clean.

3.3. Insulation

Regarding insulation, we should mention the rigid polyurethane foam formed into panels or placed into wall and roof construction. It's because the material can withstand chemical and high temperatures. Besides, it is lightweight and flame-retardant. Thanks to the closed-cell nature, polyurethane insulation also acts as an air barrier for saving energy purposes.

3.4. Doors

A strong structure of doors often includes polyurethane foam with a fiber-reinforced plastic (FRP) coating.

3.5. Windows

Vinyl and fiberglass are two ideal options for window frames. One has good impact resistance, while the other one is strong and inexpensive. Besides, in terms of burglar-proof, windows made from polycarbonate are considered better than glass ones.

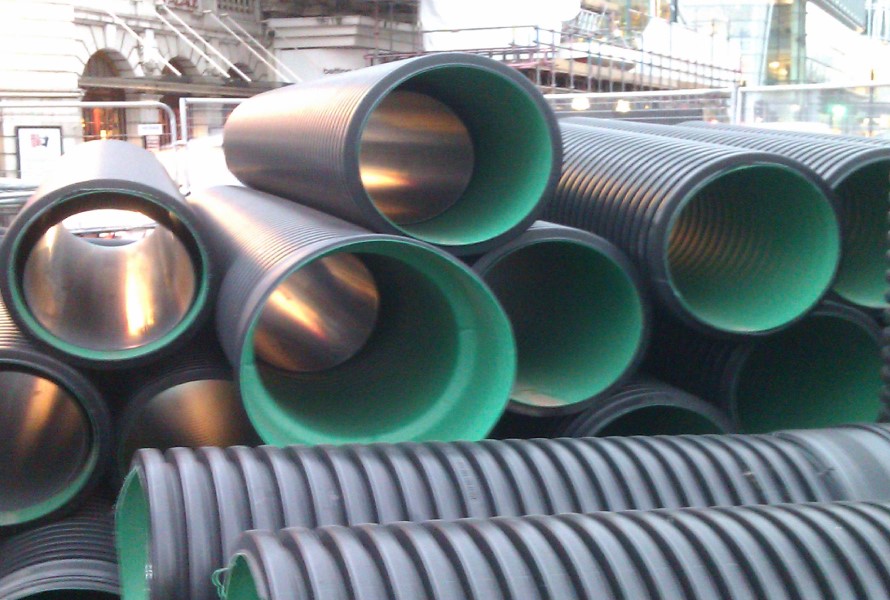

3.6. Pipes

Pipes are one of the most commonly seen applications of plastics in construction. Thanks to their lightweight and flexibility, they are easy to maneuver and install. If you want to install pipes in a harsh environment, it's no problem as the plastic materials are water and chemical-resistant. Common plastics for pipes include PVC, CPVC, acrylonitrile butadiene styrene, ABS, and polyethylene.

4. Things to consider before choosing plastics for construction

One of the disadvantages of plastics is their low modulus of elasticity and high embodied energy content. Unless they are treated (with additives, for example), they can't be used for load-bearing applications.

Plus, many varieties are ignitable and have high thermal expansion rates, so they may not be suitable for high-temperature environments or places that are easily flammable.

Since protecting our planet is part of sustainable development, go for recyclable plastics if possible to reduce the impact on the environment.

5. EuroPlas - A trustworthy manufacturer of plastic in construction

As a leader in the masterbatch manufacturing field, Europlas understands the need for a full-function-in-one material to save time and cost of production. We have a list of engineering plastic compounds blending ABS, PC, and PP resins with additives and reinforcements to enhance the properties of the final product. We aim to create a material that meets the property requirements of the final products in construction.

5.1. ABS Engineering Plastic Compound

ABS Glass Fiber Compound: It's a combination of ABS resin, glass fiber, and suitable additives. It can help increase stiffness, heat deflection temperature (HDT), and softening point (VICAT) of end-products. Its common application includes earphones, car fuel tank cap, printer and primer cartridges, and car interiors.

ABS Glass Fiber Compound: It's a combination of ABS resin, glass fiber, and suitable additives. It can help increase stiffness, heat deflection temperature (HDT), and softening point (VICAT) of end-products. Its common application includes earphones, car fuel tank cap, printer and primer cartridges, and car interiors.

ABS Antistatic compound: It's the blend of ABS resin and antistatic additive. It can prevent surface static, thus minimizing the risk of electrostatic discharge and ensuring safety during processing and product use. You can use it for mobile chargers, power sockets, electronic components, earphones, keyboards, and electronic component pallets.

ABS flame retardant compound: The compound is made of ABS resin and flame retardant additives, which are in different fire resistance levels according to UL94 standards: V0, V1, and V2. Thus, it's useful in preventing fire spread on plastic surfaces. Its applications include electronic component pallets, vacuum, electric, and electronic components.

5.2. PP Engineering Plastic Compound

For PP Engineering Plastic Compound, we have:

For PP Engineering Plastic Compound, we have:

PP glass fiber compound: It's a combination of PP resin, glass fiber, and other specific additives. The mixture has less shrinkage and has better stiffness, impact, and heat resistance. You can use it for car doors, kettle handles, rice cooker covers, etc.

PP glass bead compound: It's a mixture of PP resin, glass beads, and specific additives. It's well-known for its improvement of wear resistance of the final products, minimized cracks, and shrinkage. It's suitable for home appliances, interior, and automotive decoration.

PP talc compound: It's a blend of talc powder and appropriate additives based on end-product requirements. It has reduced shrinkage, less risk of being stretched due to temperature, and better flexural strength. Outdoor equipment, motorcycles, and car interiors are common applications.

PP BaSO4 compound: The material comprises PP resin, BaSO4, and suitable additives. It can reduce deformation and enhance stability, hardness, and gloss. It's ideal for sanitary ware, water purifiers, vacuum cleaners, rice cookers, etc.

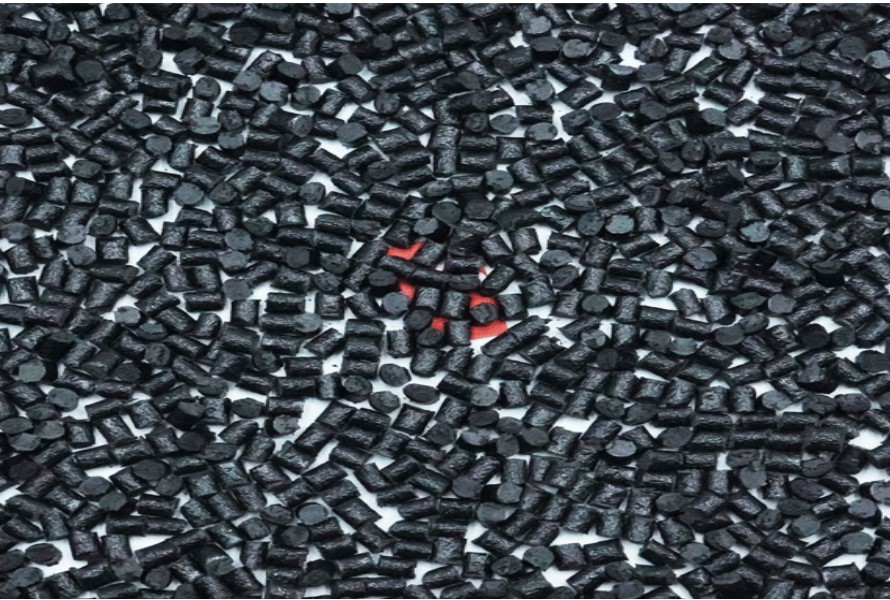

PP conductive compound: The compound combines PP resin and carbon black conductive. It helps increase the stability and conductivity of the end products. You can use it for household appliances, pumps, pipes, ESD film, etc.

PP flame retardant compound: The main components of the PP-FR compound are polypropylene (PP) resin and halogen/non-halogen flame retardant. It has better flame retardancy, which is ideal for household electrical and electronic equipment.

5.3. PC Engineering Plastic Compound

PC glass fiber compound: It is a mixture of polycarbonate resin and glass fiber. PC-GF compound has excellent properties of a thermoplastic polymer, such as rigidity, heat, and impact resistance. The material is suitable for final products requiring high stiffness and durability. Its applications include gears, keyboards, vacuum cleaners, rice cookers, cameras, and printers. EuroPlas's high-quality PC-GF compounds can be made with various glass fiber ratios to obtain specific mechanical properties that meet the customers' requirements.

PC glass fiber compound: It is a mixture of polycarbonate resin and glass fiber. PC-GF compound has excellent properties of a thermoplastic polymer, such as rigidity, heat, and impact resistance. The material is suitable for final products requiring high stiffness and durability. Its applications include gears, keyboards, vacuum cleaners, rice cookers, cameras, and printers. EuroPlas's high-quality PC-GF compounds can be made with various glass fiber ratios to obtain specific mechanical properties that meet the customers' requirements.

PC flame retardant compound: The compound perfectly combines polycarbonate resin and halogen flame retardant. It's lightweight, transparent, durable, impact-resistant, and high-temperature resistant, making it suitable for optical applications and electrical insulators. EuroPlas's mixture of polycarbonate plastic and flame retardant is available with different ratios to meet the requirement of varying UL94 standard fireproof levels such as 5VA, 5VB, V0, V1, and V2.

Depending on your purpose of use and what properties are the priority, there are various types of plastics you can use for your construction applications. Get a free consultation with EuroPlas, and we'll help you choose the best engineering plastic compound for your projects.