Geomembranes play a crucial role in environmental protection and resource management, serving as barriers to prevent fluid migration in various applications. Understanding the types of geomembrane material is vital for selecting the right solution for your project. This article explores the common plastics used in geomembranes, highlighting their unique advantages and importance in industrial applications. By choosing the appropriate geomembrane material, you can ensure durability, flexibility, and effective containment.

1. Overview of Geomembrane: Is It Important?

Geomembranes are vital components in modern engineering, particularly in environmental protection and resource management. Their primary function is to act as impermeable barriers that prevent the migration of liquids and gases, thereby safeguarding soil and groundwater from contamination. The importance of geomembrane material is underscored by its widespread use in applications such as landfills, mining operations, and wastewater treatment facilities, where it plays a crucial role in ensuring compliance with environmental regulations and protecting ecosystems. Additionally, geomembranes enhance the structural integrity of containment systems, reducing the risk of leaks and environmental damage.

With various types of geomembrane materials available, including high-density polyethylene (HDPE) and polyvinyl chloride (PVC), industries can select the most appropriate option to meet specific project requirements. Ultimately, the implementation of geomembranes is essential for sustainable practices and effective environmental management.

2. Common Plastics Used For Geomembrane Material

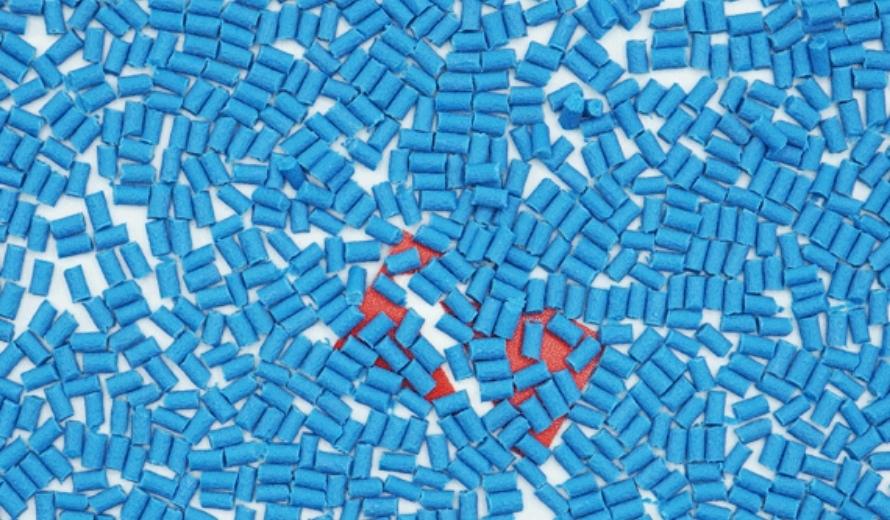

When it comes to geomembrane materials, several types are available, each offering distinct properties suited for various applications. Below is an overview of the most commonly used geomembranes:

- PVC Geomembrane: Polyvinyl Chloride (PVC) geomembranes are thermoplastic waterproofing materials composed of vinyl, plasticizers, and stabilizers. They are known for their tear, abrasion, and puncture resistance, making them ideal for applications such as canals, landfills, soil remediation, wastewater lagoon liners, and tank linings. Additionally, PVC geomembranes are effective in maintaining potable drinking water and preventing contaminants from entering water sources.

- TRP Geomembrane: Reinforced Polyethylene (TRP) geomembranes utilize polyethylene fabric for long-term water containment and industrial waste applications. They are particularly suitable for soil remediation, landfills, canals, and lining temporary retaining ponds due to their low-temperature range, chemical resistance, and ultraviolet stability.

- HDPE Geomembrane: High-Density Polyethylene (HDPE) geomembranes are characterized by strong UV and temperature resistance, durability, and high chemical resistance. They are the most commonly used geomembrane material, preferred for pond and canal lining projects, landfill covers, and reservoir applications. HDPE's chemical resistance also makes it suitable for storing potable water.

- LLDPE Geomembrane: Linear Low-Density Polyethylene (LLDPE) geomembranes are made from virgin polyethylene resins, providing strength, durability, and resistance to UV and low temperatures. They offer more flexibility compared to HDPE, making them a popular choice for industrial applications, including animal and environmental waste containment as well as liquid storage tanks.

- RPP Geomembrane: Reinforced Polypropylene (RPP) geomembranes are polyester-reinforced liners made from a UV-stabilized polypropylene copolymer. This combination provides stability, chemical resistance, and flexibility. RPP geomembranes are ideal for long-term water containment and industrial waste applications, including municipal uses, evaporation pond liners, and mine tailings.

- EPDM Geomembrane: Ethylene Propylene Diene Monomer (EPDM) geomembranes feature a rubber-like texture that contributes to their durability, UV stability, strength, and flexibility. They are particularly effective in extreme weather conditions and are resistant to punctures. EPDM geomembranes are commonly used as surface barriers for dams, liners, covers, and in landscaping and irrigation applications.

Read more: Compare HDPE, MDPE, LDPE, and LLDPE masterbatch

3. Advantages of Each Plastic Type

When selecting geomembrane materials for various applications, understanding the advantages of each plastic type is crucial for ensuring optimal performance and longevity. Below are the key benefits of the most commonly used geomembrane materials:

High-Density Polyethylene (HDPE): HDPE geomembranes are celebrated for their durability and chemical resistance. They provide excellent protection against UV radiation, chemicals, and extreme temperatures, making them ideal for long-term containment applications. Commonly used in landfills and waste ponds, HDPE effectively prevents the leakage of harmful substances. Its impermeability to water and gas makes it suitable for mining pond linings and sewage systems. Additionally, HDPE has a longer lifespan compared to many other geomembrane types and requires minimal maintenance over time.

- Low-Density Polyethylene (LDPE): LDPE geomembranes are recognized for their superior flexibility, which facilitates easier installation in projects requiring intricate fitting and lining. This material also offers good resistance to chemicals and UV radiation, making it suitable for outdoor applications. LDPE's adaptability allows it to conform to various shapes, enhancing its usability in diverse environments.

- Linear Low-Density Polyethylene (LLDPE): LLDPE geomembranes strike an effective balance between the flexibility of LDPE and the strength of HDPE. They are more flexible than HDPE, which simplifies installation, while still maintaining high strength and puncture resistance. LLDPE is resistant to chemicals and UV radiation, making it a versatile choice for a wide range of containment applications, including environmental, industrial, and agricultural uses.

- Polyvinyl Chloride (PVC): PVC geomembranes are highly flexible, allowing for easy installation even in complex configurations. Their ability to conform to the underlying terrain is particularly beneficial for applications such as pond and canal linings. PVC also offers excellent chemical resistance, making it ideal for chemical containment applications, including waste management and industrial ponds.

- Ethylene Propylene Diene Monomer (EPDM): EPDM geomembranes are renowned for their exceptional flexibility and elasticity, making them an excellent choice for applications that require significant ground movement or flexibility. They are commonly used in water reservoir linings, decorative ponds, and irrigation systems. EPDM is highly resistant to UV radiation and possesses good chemical resistance, making it suitable for outdoor applications.

- Chlorosulfonated Polyethylene (CSPE): CSPE geomembranes provide superior resistance to UV radiation, ozone, and harsh chemicals, making them ideal for long-term outdoor applications where exposure to the elements is a concern. They are often utilized in potable water reservoirs, industrial waste containment, and roofing membranes due to their exceptional durability.

4. Conclusion

In conclusion, selecting the right geomembrane material is essential for effective containment and environmental protection. Each plastic type, from HDPE to EPDM, presents distinct advantages tailored to specific project requirements, including chemical resistance and flexibility. Understanding these characteristics enables informed decision-making, enhancing the performance and longevity of geomembrane systems. Ultimately, the right choice ensures compliance with environmental standards and safeguards valuable resources.

5. About EuroPlas

EuroPlas offers a comprehensive solution with its engineering plastic compounds, designed to meet the diverse needs of various industries. These compounds consist of a primary resin, colorants, and reinforcements, enabling the production of high-quality finished products with specific technical properties. Ideal for applications in automotive, electronics, and household appliances, EuroPlas engineering plastic compounds include advanced materials such as PBT GF-FR, PA6, PA66, and ABS fiberglass compounds.

With a focus on flexibility and functionality, EuroPlas ensures that customers receive innovative solutions tailored to their requirements. For more information or to discuss your project needs, please contact us.