Welcome to our comprehensive guide on polyamide vs nylon, two fascinating synthetic polymers that have revolutionized various industries. This article will delve into the definition, properties, and applications of polyamides and nylons. We will also compare the differences between these materials and provide insights on which one to choose for specific requirements. Additionally, we will introduce EuroPlas PA, a notable nylon engineering plastic compound, and address common questions in our FAQs section. So let's also find out what’s polyamide, what is nylon and explore its properties?

1. What is Polyamide?

1.1. Definition of Polyamide

Polyamide, classified as a synthetic polymer within the family of engineering plastics, is widely recognized for its remarkable attributes encompassing exceptional strength, durability, and resistance to various external influences. This versatile material consists of repetitive units intricately interconnected by amide bonds, endowing it with its distinctive and advantageous properties.

1.2. Types of Polyamide

Within the realm of polyamide plastic, diverse forms exist, each exhibiting its own distinct set of characteristics. Noteworthy variants of this polymer include PA6, commonly referred to as Nylon 6, PA66, or Nylon 66, and PA12, also known as Nylon 12. These distinct permutations offer various mechanical, thermal, and chemical properties, allowing engineers to select the most appropriate type for their specific applications based on the desired attributes.

1.3. Common Applications of Polyamide

Polyamide applications extend across various industries, with special implementation in the automotive sector, electrical and electronics domain, textiles, and consumer goods market. Polyamide nylon deployment predominantly revolves around producing components necessitating exceptional strength, impact resistance, and dimensional stability. Polyamide is an indispensable material in many applications, from intricate gears and robust bearings to dependable electrical connectors and protective casings.

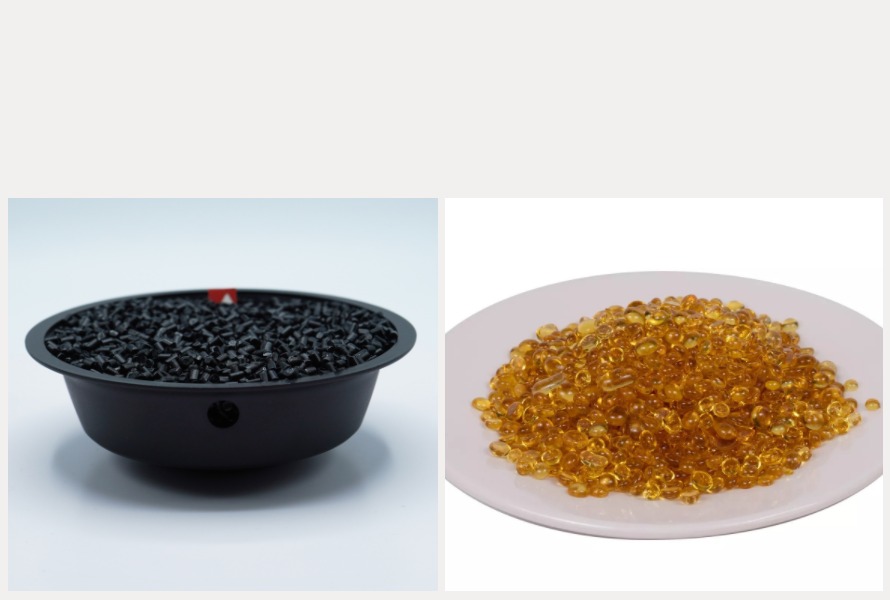

What is Polyamide Material

2. Polyamide Material Properties

Polyamide exhibits an impressive array of material properties, making it suitable for diverse applications. Some fundamental properties to note include the following:

2.1. Strength and Durability

Polyamide showcases remarkable tensile strength, ensuring resilience against wear and tear. It can withstand heavy loads without succumbing to breakage or deformation under stress. Additionally, it demonstrates excellent resistance to chemicals and UV radiation, making it an ideal choice for outdoor applications. For instance, the construction industry frequently relies on polyamide for building materials like pipes and fittings due to its durability and resistance to corrosion.

2.2. Flexibility and Elasticity

Polyamide boasts high flexibility and exceptional elasticity. It can be stretched without losing shape and swiftly returns to its original form after deformation. This property makes it an excellent material for textiles, including athletic clothing and hosiery, where flexibility and comfort are paramount. Moreover, the automotive industry utilizes polyamide for components such as air intake systems and fuel lines, benefitting from its elasticity to withstand vibrations and fluctuating temperatures.

2.3. Heat Resistance

Polyamide demonstrates commendable heat resistance, preserving its Polyamide structure integrity even at high temperatures. This quality renders it suitable for applications exposed to heat or friction. For example, it is extensively employed in producing engine components like gears and bearings, which endure high temperatures and friction. Additionally, it finds utility in electrical insulation materials due to its ability to maintain shape and structure at elevated temperatures.

2.4. Chemical Resistance

Many substances, including acids, alkalis, and organic solvents, are resistant to polyamide. This characteristic guarantees its use in industries where workers deal with various chemicals.

For instance, polyamide is used to create tubing and filters in the pharmaceutical sector that come into touch with numerous chemicals when taking drugs. Moreover, because of its resistance to deterioration from exposure to gasoline and other fuels, it is also used to manufacture vehicle fuel lines.

Polyamide Material Properties

3. What is Nylon? Is Nylon Thermoplastic?

- Explanation of Thermoplastic Materials: Before diving into whether nylon is thermoplastic, let's understand what thermoplastic materials are. Thermoplastics are a class of polymers that soften when heated and can be molded into various shapes. They exhibit excellent processability, allowing for easy recycling and reshaping without significant degradation in their properties.

- Nylon as a Thermoplastic: Nylon is indeed a thermoplastic material. Its ability to melt and solidify repeatedly without undergoing any chemical change makes it an excellent candidate for various manufacturing processes. Injection molding, extrusion, and 3D printing are common methods used to process nylon plastic, providing engineers with flexibility and design freedom.

Nylon as a Thermoplastic

Read more: What is nylon? All about its properties and common uses

4. Nylon Material Properties

Nylon shares numerous material properties with polyamide while also possessing some unique characteristics. Here are a few special properties to consider:

- Chemical Structure: Nylon structure consists of two chains of six carbon monomers connected to a COOH group at one end and an amino group, or NH2, at the opposite end. Two monomers that make up nylon can be replicated to create long polymer nylon chains.

- Excellent Strength-to-Weight Ratio: Nylon plastic offers an impressive strength-to-weight ratio, rendering it ideal for applications requiring lightweight materials with high strength. It is widely utilized in automotive components, sports equipment, and industrial parts. For instance, it finds application in tennis racket strings, which are light enough to avoid impacting the player's swing yet sturdy enough to withstand the force of hitting the ball. In machinery, nylon gears and bearings handle high loads without quick wear or breakage.

- Moisture Absorption: Nylon can absorb moisture from its surroundings, impacting its dimensional stability and mechanical properties. However, this characteristic can be controlled through the addition of additives during the manufacturing process. For example, nylon fishing lines utilize moisture absorption to enhance flexibility and casting ability. Conversely, nylon gears for machinery incorporate additives to prevent moisture absorption and maintain dimensional stability.

- Low Friction Coefficient: Nylon boasts a low friction coefficient, which imparts excellent self-lubricating properties. This feature makes it ideal for applications involving sliding or rotating components, such as bearings and gears. Machinery frequently relies on nylon gears due to their ability to operate with minimal lubrication, reducing the risk of damage from abrasion. Additionally, nylon bearings find utility in skateboard wheels, providing a smooth ride thanks to their low friction coefficient.

- Electrical Insulation: Nylon is an exceptional electrical insulator, making it a preferred choice for electrical and electronic applications. Its high dielectric strength and low conductivity prevent electrical failures and ensure safe operation. Nylon gears for machinery leverage this property, while electrical components like circuit breakers and switches commonly incorporate Nylon due to their exceptional electrical insulation properties.

Nylon Material Properties

5. Polyamide vs Nylon: What Are the Differences?

Many people could be perplexed by the frequent interchangeability of the words polyamide vs nylon. It's critical to understand that nylon represents a very minor percentage of the larger family of polyamides. It's important to realize that although nylon is a subset of polyamides, not all polyamides may be categorized as nylons. We may be able to clarify the differences between polyamides and nylons by diving more into the complex interactions that occur between the two materials.

- Terminology Polyamide vs nylon: Polyamide, as a comprehensive term, encompasses a diverse array of polymers characterized by the presence of amide linkages within their molecular structure. This expansive category comprises numerous materials, each possessing its own distinct properties and applications. Conversely, nylon emerges as a specific subtype of polyamide and holds the distinction of being the pioneering commercially successful synthetic fiber.

- Manufacturing Process of Polyamide vs nylon: Polyamide can be manufactured using various methods, including polycondensation and ring-opening polymerization. On the other hand, Nylon, as a type of polyamide, is typically manufactured through a specific polycondensation process.

- Chemical Structure of Polyamide vs nylon: Polyamide can exhibit different chemical structures depending on the monomers employed during production. As a polyamide type, Nylon possesses a distinct chemical structure incorporating amide linkages in the polymer chain.

- Applications of Polyamide vs nylon: Polyamide has extensive applications across various industries, encompassing textiles, automotive, and consumer goods. As a polyamide subtype, Nylon is widely employed in applications demanding high strength, durabilities, and heat resistance, such as gears, bearings, and synthetic fibers.

Material Polyamide vs Nylon

6 . Polyamide vs Nylon: What Should be Chosen?

Choosing between polyamide vs nylon depends on several factors, including the specific application requirements, cost considerations, and market availability.

- Factors to Consider of Polyamide vs nylon: When selecting between polyamide vs nylon, evaluating the desired properties, such as strength, heat resistance, chemical resistance, and electrical properties, is crucial. Assessing the application's environmental conditions, load-bearing capacity, and design complexity will help determine the most suitable material.

- Specific Applications and Requirements of Polyamide vs nylon: Certain applications may demand specific material properties, such as high heat or superior chemical resistance. Understanding the application's unique requirements will guide the selection process, ensuring that the chosen material meets the desired performance standards.

- Cost and Availability of Polyamide vs nylon: Cost is an essential consideration in any manufacturing process. While nylon may be more expensive than other polyamide variants, it might still be the optimal choice for applications that demand its specific properties. Additionally, evaluating the availability of the chosen material in the market is crucial to ensure a reliable supply chain.

- Future Trends and Innovations of nylon vs Polyamide: The field of engineering plastics is continuously evolving, with ongoing research and development efforts to enhance the properties of polyamide vs nylon. Keeping an eye on emerging trends and innovations can provide valuable insights into new materials and potential advancements in the field.

Polyamide vs Nylon: What Should be Chosen?

7. Conclusion

In conclusion, when selecting to define polyamide vs nylon material for a manufacturing process, cost and availability should be considered, but it is also important to evaluate the specific properties required for the application. While nylon may be more expensive than other polyamide variants, it may still be the optimal choice for certain applications. It is also important to keep up with emerging trends and innovations in the field of engineering plastics to stay informed about potential advancements and new materials.

8. Introduction of EuroPlas PA (Nylon) Engineering Plastic Compound

8.1. Overview of EuroPlas PA compound

EuroPlas PA compound is an innovative engineering plastic compound that combines the advantages of polyamide (nylon) with specific reinforcements and additives to meet specific application requirements. It is designed to provide enhanced performance and superior properties in demanding environments.

EuroPlas PA (Nylon) Engineering Plastic Compound

8.2. Unique Features and Benefits

EuroPlas PA offers several unique features and benefits that set it apart from traditional polyamide vs nylon materials. These include improved mechanical properties, enhanced heat resistance, superior chemical resistance, and reduced moisture absorption. EuroPlas PA is an excellent choice for critical applications where performance and reliability are paramount.

8.3. Applications of EuroPlas PA

EuroPlas PA finds application in various industries, including automotives, electrical and electronics, and industrial manufacturing. It is used in components such as gears, bearings, connectors, and housings, where exceptional strength, durability, and resistance to challenging environments are required.

Please contact us for more details!

9. FAQs

What is a polyamide?

Polyamide is a polymer that contains repeating units linked by amide bonds. Amide groups have the general chemical formula CO-NH. Polyamides occur both naturally and artificially. Examples of naturally occurring polyamides are proteins such as wool and silk.

Does polyamide shrink?

Polyamide is not supposed to shrink. This fabric was designed to hold its shape and to get the material to stretch well, it needs to be blended with elastane. However, some people claim you can shrink polyamide by using heat. The results may not be that good.

Is Nylon a good choice for applications that require moisture resistance?

Nylon can absorb moisture, which can impact its properties. However, specific types of Nylon can be selected for applications that demand excellent moisture resistance.

Can polyamide vs nylon be recycled?

Both polyamide vs nylon can undergo recycling. The recycling process involves melting the material and reforming it into new products. Recycling contributes to waste reduction and resource conservation.

Where can I find EuroPlas PA (Nylon) engineering plastic compounds?

Authorized distributors and suppliers offer EuroPlas PA (Nylon) engineering plastic compounds. For more information and specific product inquiries, please visit EuroPlas official website or contact us.