Innovative and cost-saving materials are what all manufacturers in the world are looking for. Polybutylene terephthalate is one of the ideal candidates for that purpose. It has many outstanding features to be chosen in a variety of industries, including automotive and electronics.

Let's discuss more about its properties and how it can benefit your business in our article below! We'll give you all the information you need about this material.

1. What's a PBT?

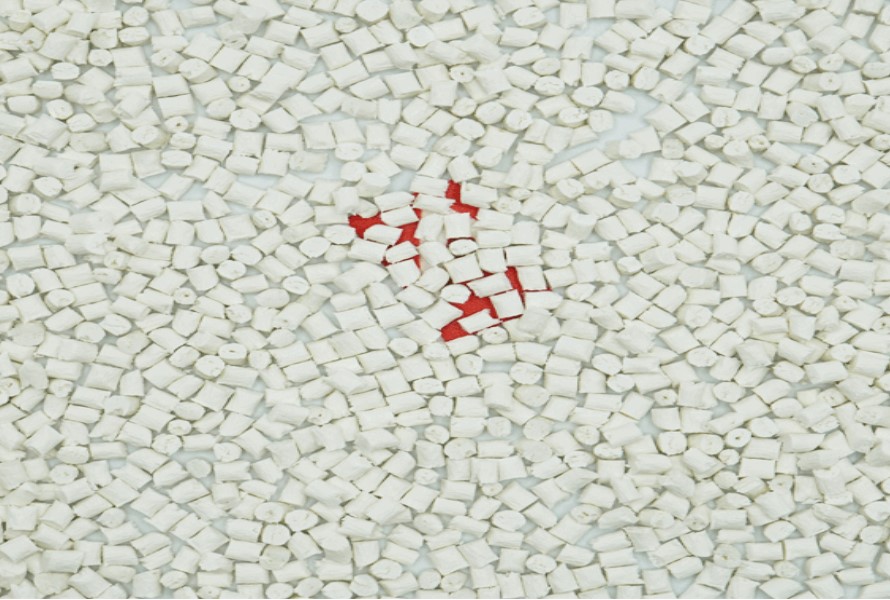

PBT stands for Polybutylene terephthalate, a member of the polyester polymer family. It has many compositions and mechanical properties similar to its sibling, PET or Polyethylene Terephthalate. PBT is known as a semi-crystalline thermoplastic compound widely used in various industries.

Polybutylene terephthalate is formed by the polymerization or polycondensation process of butanediol and terephthalic acid. It also can be made of dimethyl terephthalate, 1,4-butanediol, and a special catalyst.

Thanks to its benefits, the material has a wide range of uses, such as electrical applications, electronics, automotive, and medical fields. The various grades of PBT are great for injection molding, including filled, reinforced, impact-modified, and flame-retardant. Manufacturers also can make glass-reinforced polybutylene terephthalate to achieve extra flexural tensile and compressive strength.

Plus, PBT is VDE, UL (for electronic and electrical appliances), and FDA (for food and medical markets) approved, making it a reliable material.

2. Characteristics and Properties of Polybutylene Terephthalate

2.1. Physical Properties

PBT has good dimensional stability and low moisture absorption properties. This highly elastic, friction-textured material possesses good stretch properties and unique recovery properties. Its low humidity take-up levels (only around 0.4%) allow it to dry quickly and have high resistance to perspiration and humidity. Thermal stress and harsh chemical environments are not a problem for the material as it's very durable. That's why it's often used for automotive underhood applications.

2.2. Thermal Properties

PBT is well-resistant to long-term heat exposure and short-term thermal excursions. It's because the material obtains a high-temperature index rating and a high heat-deflection temperature.

2.3. Mechanical Properties

Polybutylene Terephthalate is strong, tough, and stiff, indicating a good practical impact. It can withstand steady and elevated temperatures. Its tensile strength can be up to 17,000 PSI.

2.4. Chemical Resistance

The material can tolerate a wide range of chemicals, including alcohols, diluted acids, ketones, aromatic hydrocarbons, solvents, greases, and oils. Thus, many manufacturers prefer PBT to produce plastic components exposed to organic oil, gasoline, and solvents. It also possesses good resistance to erosion, stain, and UV rays.

2.5. Electrical Properties

Since Polybutylene Terephthalate has high electrical resistance and dielectric strength, it's used in electronic and electrical components to avoid discharge. It also protects the components from power leakage and breakdown. You don't need to worry about energy absorption if the detail is frequently used, as it's eliminated by the low dielectric loss.

2.6. Other Outstanding Features

PBT has excellent other machining characteristics helping enhance efficiency uses and reducing cost. It's safe to use for medical, food, and potable water applications.

3. How to Process PBT?

The general method of processing Polybutylene Terephthalate is injection molding at the temperature of 230°C to 270°C. Other methods include extrusion and blow molding. Meanwhile, special extrusion and fiber spinning processes are applied to produce unreinforced PBT.

Sometimes, you can find PBT made from other methods such as profile, tube, monofilament extrusion, and melt-blown and spun-bond processes. Allowing the material to be through an optimum cooling temperature of 250 to 275°F for 2 to 4 hours will produce the best product.

4. Applications of Polybutylene Terephthalate

PBT, including PBT resin and PBT compound, is commonly seen in many daily life applications, such as automatic e, electrical and electronic components. PBT compound combines PBT resin, fiberglass filing, and additives. The material also presents in mineral or glass-filled grades.

When Polybutylene Terephthalate is mixed with additives, its UV and flammability properties are improved, making it suitable for numerous industrial applications, including outdoor sections where fire is highly concerned.

You can find PBT resin in electrical, electronic, and automotive components and PBT fiber. Some examples are motor covers, motor details, and TV set accessories. After being reinforced, the material is suitable for making bobbins, sockets, handles, and switches. Meanwhile, brake cable liners and rods use the unfilled versions of PBT.

Since Polybutylene Terephthalate is strong, dimensionally stable, resistant to many chemicals, able to insulate well, and has good bearing and wearing properties, it's an ideal choice for wheels, valves, gears, and food processing machinery details. Besides, it can go well with staining and absorb low moisture but does not absorb flavor, allowing it to be presented in many food processing components.

In addition, PBT yarn is popular. Its natural stretch is similar to Lycra, plus its chlorine resistance, making it possible to use to make sportswear, such as swimwear, tracksuits, cycling wear, jogging clothes, gymnastic clothing, etc. Underwear (bodies, ladies' lingerie) and outerwear (leisure trousers, children's Lycra-wear) made from PBT are also commonly seen.

5. EuroPlas PBT GF-FR Compound - An Innovative Solution for Your Products

EuroPlas is a professional company producing excellent engineering plastic compounds for different industries. Our products are well-known for their thermal resistance and mechanical properties. And

PBT GF-FR Compound is one of them.

It integrated all functions in one single material by combining PBT plastic with glass fiber reinforcements, color, and flame retardant additives. Thus, you can directly process it without any material added. It also can be tailor-made based on the final products' requirements.

Our PBT GF-FR Compound has high stiffness, long-term heat aging stability, durability, longevity, flame retardancy, the ability to prevent abrasion and discoloration due to UV light, and financial benefits, making it suitable for a wide range of utilization such as car interiors, electrical engineering, kitchen equipment, and household appliances.

Our material also obtains glass fiber ratios and fire resistance levels that meet the UL94 standards, including 5VA, 5VB, V0, V1, and V2. Therefore, EuroPlas is confident to be your reliable supplier for PBT GF-FR Compound and other products.