There is no doubt that polypropylene is the most versatile thermoplastic whose applications and fields of application spread across a wide variety of industries: packaging, automobile, textiles, and consumer goods. In recent years, polypropylene has shown significant volatility in the market. Via this post, we’ll give you a forecast about polypropylene price and the next step for this.

1. Factors influencing polypropylene price

1.1. Crude oil and natural gas prices

Polypropylene is mainly produced from propylene, a secondary product from the processing of natural gas and crude oil distillation. Due to this, polypropylene price is extremely affected by propylene pricing fluctuations, specifically oil and natural gas pricing. If there is an increase in crude oil or natural gas pricing, the price of polypropylene supply and production costs will rise. In contrast, the reduction of them will lead to a decrease of polypropylene prices.

Crude oil and Natural gas prices are some of the factors influencing polypropylene price.

1.2. Supply and demand dynamics

Polypropylene price can be significantly affected by the delicate balance between the supply of polypropylene and demand for it. Polypropylene prices tend to rise when there is a high demand for this plastic material due to limited availability in the market.

On the other hand, when buyers’ needs exceed the supply of polypropylene, there is a likelihood for prices to fall due to sellers attempting to sell off their stocks. Consequently, enterprises need information on factors that influence the price of polypropylene so that they can make the right decisions and set up plans for sustainable expansion.

1.3. Market competition

Their polypropylene price and strategies may be affected by the level of competition among the producers and traders. Manufacturers may want to maintain competitive prices on polypropylene thus; they will retain their market share in a competitive market while producers may have pricing power when markets are more concentrated.

The landscape of polypropylene price is significant as it has a potential impact on cost structures and profitability levels among organizations that utilize this vital substance.

The competition between PP producers and traders has an impact on polypropylene price.

1.4. Transportation and logistics costs

The final polypropylene price might include transport e.g. freight, warehousing and forwarder costs from production sites to end-users. Fuel prices, transportation infrastructure and supply chain disruptions, for example, can drive polypropylene pricing higher.

For businesses to properly evaluate their cost structures and business decisions around procurement and pricing, they need to understand how these logistical factors impact the price of polypropylene. Watching and properly managing the numerous cost factors that affect the polypropylene price allows businesses to continue to measure up to their competitors and be profitable in the industry.

1.5. Trade policies and tariffs

The global availability and pricing of polypropylene could depend on import/export tariffs, trade agreements, and other actions a government may take in the regulatory arena. For example, there is an increase in tariffs for the imports of polypropylene and the smooth free flow of polypropylene that may lead to the advantage of the polypropylene price.

For business houses, it is essential to keep an eye on how these policy changes will affect the cost of polypropylene and what they have to do to prepare for such eventualities so that their business remains in competition and hence profitable.

Government policies on trade, tariffs, and regulations can significantly affect polypropylene prices.

1.6. Sustainability and environmental regulations

The sustainability perspective and changing environmental policies that are associated with emissions, waste treatment, and recycling are all factors that may influence cost structures or price strategies within the polypropylene manufacturing sector. With such developments, there is bound to be a change in the polypropylene price.

The firms dependent on polypropylene have to track these leading-edge moves in sustainability initiatives and regulatory shifts to be able to make informed decisions and sustain their competitive edge. An important aspect is the realization of the relationship between environmental factors and polypropylene price fluctuations.

2. Polypropylene price forecasts: What’s next?

The global polypropylene market is heavily influenced by fluctuations in crude oil prices. This creates volatility in polypropylene price. According to data from the U.S. Energy Information Administration (US EIA) crude oil prices are expected to increase through 2024. Demand is anticipated to rise faster than supply.

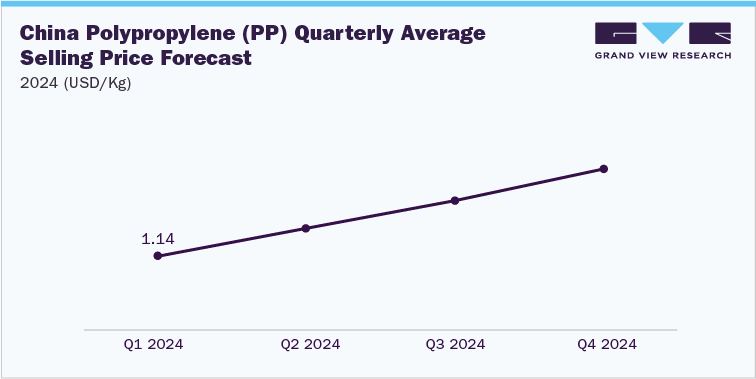

In the Chinese market, it is forecasted that polypropylene price will gradually increase. This is likely to continue to be the case throughout 2024, driven by the rise in global crude oil prices during 2024. The increase in polypropylene costs in China is also expected to be an upward steady trend.

According to Grand View Research, the price of polypropylene is predicted to continuously increase in China.

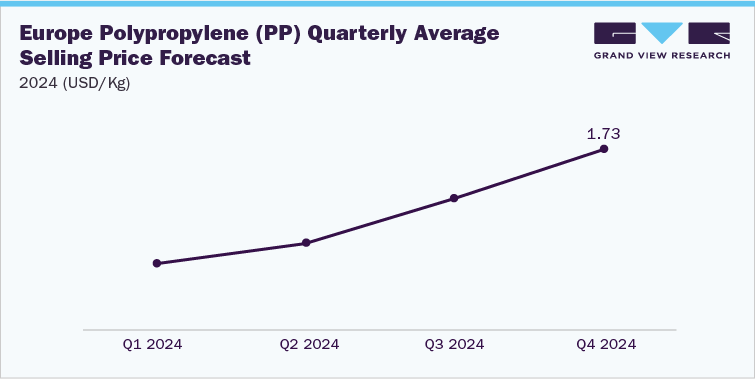

The polypropylene price in the European market is expected to rise with increased volatility during 2024, driven by the automotive industry. This segment is one of the largest consumers of polypropylene in Europe. The expected growth in the sale of vehicles in turn will drive higher demand for polypropylene. Accordingly, the value of polypropylene in the European market is expected to rise. Consequently, the polypropylene prices on the European market will experience greater changes.

As forecasted by Grand View Research, the price of polypropylene in Europe Is going to rise up during 2024.

3. Strategies for Manufacturers and Consumers

3.1. For manufacturers

To manage expected polypropylene market volatility, manufacturers must closely monitor key factors. For instance, the price of crude oil, a critical driver of the production costs of polypropylene, demands a close watch on the global price and an alignment of the same with the production plan and strategies on polypropylene price.

Shifts in demand from major end-use industries, particularly automotive, will significantly influence the dynamics of the PP market. Since the automotive industry is a major consumer of PP, any shifts in vehicle production and sales will have a spillover effect on the demand for PP. Manufacturers thus need to closely follow trends in the automotive industry and make realignments in the production of PP to meet changes in customer needs, which will have a bearing on polypropylene prices. Closely following these factors can help manufacturers navigate through the anticipated volatility and remain competitive.

3.2. For consumers

With the gradual polypropylene price increases customers need to apply strategic purchasing with flexibility in planning the needed costs carefully. Long-term supplier contracts, with some price fluctuation, can offer better supply security and, with that, advantageous terms, especially for critical resin grades.

Customers should diversify suppliers, this helps reduce the risk of them having to deal with supply disruptions. Diversification can offer customers negotiation leverage. Regular benchmarking of polypropylene pricing and service levels throughout the supply network gives assurance of competitive terms. Customers can limit the impacts of gradually increasing polypropylene prices by strategically managing their polypropylene supply and being flexible.

4. Conclusion

Polypropylene prices are likely to remain erratic also in the next few years with numerous factors interacting with the supply/demand balance. Manufacturers and customers alike need to adopt a flexible approach and need to keep a close ear on market intelligence. This way they can navigate the erratic environment in polypropylene pricing as well as guarantee a proper handling of polypropylene's challenges and opportunities in evolution.

5. About EuroPlas’ polypropylene products

With nearly 17 years of industry experience, EuroPlas has established itself as a renowned manufacturer of filler masterbatch. The company offers a diverse portfolio of high-quality Polypropylene plastic solutions to cater to a wide range of application needs.

EuroPlas' PP product range includes:

- PP Filler Masterbatch

- PP Flame Retardant Compound

- PP Conductive Compound

- PP BaSO4 Compound

- PP Talc Compound

- PP Glass Bead Compound

- PP Glass Fiber Compound

To learn more about EuroPlas' extensive range of polypropylene plastics, please visit PP Search - EuroPlas - The world's No1 filler masterbatch manufacturer or contact us for consulting polypropylene price now.