Composite materials are dominating the manufacturing industries

According to current trends, composite plastic materials are gradually dominating the manufacturing industries. With properties that are no different or even superior to those of wood or metal, composite materials also bring great cost benefits. With low prices, not too complicated production processes, lightweight and easy construction, composite materials are always a great choice. To understand more about the application of composite materials in practice, we invite you to immediately learn about some of the most popular composite material processing methods today!

1. What is composite material?

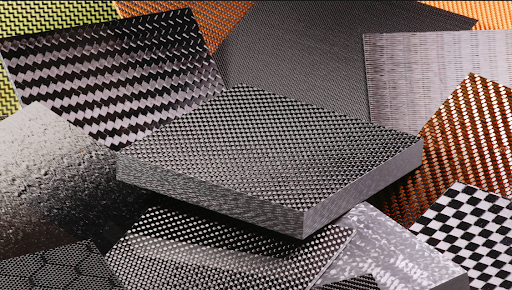

Composite material is a combination of two or more components

Composite materials are understood as the combination of two or more components to create a new material without dissolving the components together. Composite materials are created by taking one material (matrix) and surrounding it with fibers or flakes of a stronger material (reinforcement). The reason for this combination process is to improve the properties of the material. The newly created material will have the superior properties of the component materials, thereby helping us obtain a more perfect material. In fact, composites are often more durable and have better properties than their predecessors. According to statistics, there are currently 3 basic types of composite materials: thermoplastic, thermosetting plastic and mixed plastic. In production life, people widely use composite materials in many different industries thanks to their durability, lightness, flexibility and ease of processing. These include industries such as automotive technology, aircraft and aerospace technology, ship design, construction projects, etc. Among them, the medical industry is also one of the fields that favor composite materials. in research and treatment.

Read more: Different types of composite materials you should know

2. What are some popular composite materials?

2.1 Polymer matrix composites (PMC)

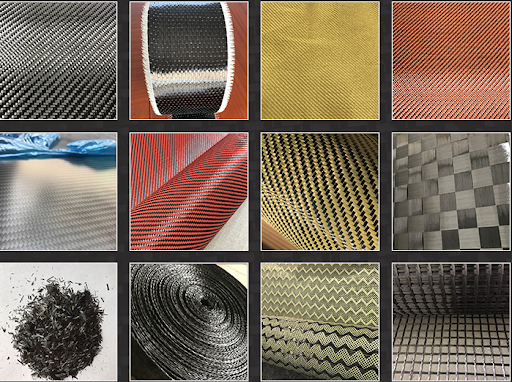

Plastic will act as the matrix in Polymer matrix composites

This is a group of composite materials in which plastic will act as the matrix that forms the foundation for reinforcing molecules to bond together. This combination gives the new material much more special properties than conventional plastic. Some of them can be mentioned as follows:

- PMC is reinforced with glass fibers: glass fibers will be woven into a plastic matrix with outstanding properties of strength and stiffness. Thanks to that, this material will perfectly meet the needs of processing light and sturdy products.

Read more: Glass fiber reinforced plastic: definition and pros & cons

- PMC is reinforced with aramid fibers: aramid fibers will be an ideal choice for applications that emphasize durability and protection thanks to their super strength, toughness and excellent heat resistance. This is also a material to consider for applications where durability and lightness are important.

Read more: What is Aramid fiber?

- PMC is reinforced with carbon fiber: carbon fibers are widely known for their high-performance properties thanks to their strength-to-weight ratio. This would be a great choice for applications where weight is a concern.

Read more: What is carbon fiber?

2.2. Metal Matrix Composites (MMC)

Metal Matrix Composites application in aerospace

This is a group of composite materials in which metal acts as a matrix that forms the basis for reinforcing molecules to bond together. This is a combination of the strength of the metal and the lightness of the reinforcing material. People recommend this combination for applications that require high load capacity and weight savings. Some of them can be mentioned as follows:

- Magnesium MMC: magnesium matrix material is widely known for its light weight and high strength-to-weight ratio. To further strengthen the properties of the material, the reinforcement can include some materials such as silicon carbide or boron nitride.

- Aluminum MMC: Aluminum will serve as the matrix material and is typically reinforced with silicon carbide or alumina. This material possesses anti-abrasion properties, good durability and hardness but is quite light in weight

- Titanium MMC: titanium will serve as the matrix material and the reinforcing fibers will be either silicon carbide or carbon fibers. This combination will increase their strength, high temperature performance and wear resistance capabilities.

2.3. Ceramic matrix composites (CMC)

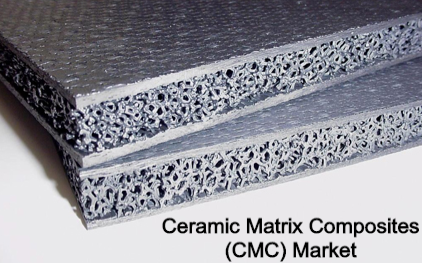

Ceramic matrix composites enhances the properties of each other

This is a mutually supportive blend of materials that enhances the properties of each other. The ceramic base is usually silicon carbide or alumina and the reinforcing fibers can be carbon or silicon carbide. This will improve the flexibility and toughness of the material to help it withstand incredible impacts such as:

- Alumina CMC (Al2O3 CMC): industries such as biomedicine, electronics and automotive technology quite favor Al2O3 CMC. The main reason is that this material possesses wear resistance, high durability and resistivity.

- CMC silicon carbide (SiC CMC): SiC CMC is one of the optimal choices for aerospace and industrial applications thanks to its super durability, high heat resistance and excellent abrasion resistance.

- Boron Nitride CMC (BN CMC): this is also one of the bright candidates for applications requiring elite performance and durability.

3. Popular methods of processing composite materials

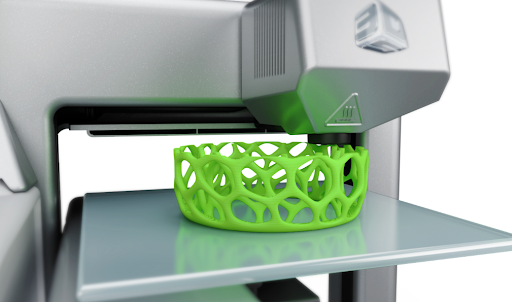

3D printing brings many advantages

Processing composite materials using 3D printing (3-Dimension) brings many advantages compared to traditional processing methods such as time savings, and the ability to print many complex designs etc. 3D printing operations are understood as a form of additive manufacturing in which printing programs are pre-programmed. The printer or printing software will set up sequentially and repeatedly until the product is complete. This is one of the processing methods that brings the most vivid products.

Read more: 3D printing vs Injection molding: Which way is appropriate?

Aircraft fuselage produced by Automated Layup

- ATL / AFP – Automated Layup

Processing composite materials with ATL / AFP – Automatic layout is understood as a process of using automation equipment to create new products. This method requires advanced machinery and software, so the cost is quite high, so it is suitable for long-term production. However, the advantages that this method brings will be difficult to compare with any other process. The machining process can take place day and night, and every movement in the shaping process will be controlled with extremely high quality and almost perfect accuracy. In particular, ATL is suitable for applications with large and flat surfaces (for example, wing covers or fuselage). The additive process using AFP will favor smaller and more sophisticated designs.

- Resin Transfer Molding (RTM)

Adding composite materials using this method can be understood as the process of using a pump or pressure tank to push plastic into a mold at high pressure (about 150-300psi - 1500psi) depending on production needs. The advantage of Resin Transfer Molding (RTM) is speed and high automation. This method also requires an initial investment in equipment, but the volume and speed of production will be extremely impressive. This method is suitable for parts with small designs and accommodates a wide range of shapes

Compression Molding products

The compression molding method is a processing process using a mold set and some other machine accessories. The plastic will be available in an open mold and then compressed using a large hydraulic press and some processes carried out under extremely high pressure. This is an application method for thermosetting plastics, thermoplastics and many other fibers.

Filament Winding is suitable for simple rotating shapes such as cylinders or tubes

This is one of the highly developed methods. This is a method of wrapping fibers onto a shaft according to a certain design to create a finished product. The filaments are typically wetted with resin then wound around a mandrel. The mandrel will be rotated by a guide moving along the length of the mandrel. Because the processing process is quite specific, Filament Winding is suitable for applications with simple rotating shapes such as cylinders or tubes.

The additive process is understood as the composite material will be mixed and sprayed with a gun into fibers. This method has the disadvantage that it is difficult to control the thickness, which in turn affects the product weight. However, this is an ideal solution for parts that are gel-coated or have complex geometries such as shower walls, tanks, home design equipment and vehicle parts, etc. This process requires skillful workers to ensure a perfect surface to avoid the appearance of voids or deformation.

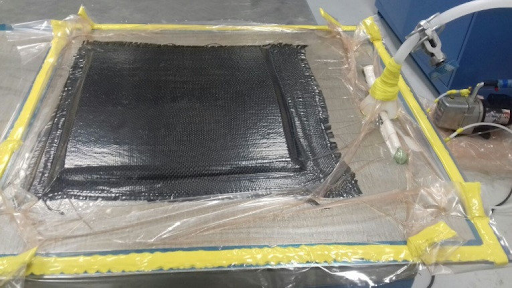

Vacuum Bagged Wet Layup processing

This is a bagged wet layering process until all the composite material is pressed into the mold. The plastic layer will be reinforced and excess plastic layers removed before solidifying with a vacuum bag and accompanying packaging accessories. This is one of the processes that requires highly skilled machinists because the process will depend on production needs and requires careful calculation.

This is a method where a stack of dry reinforcing fibers goes into a mold, then a vacuum bag (CCCBM) goes into that mold. We perform a vacuum on the bottom of the bag so that the pressure difference between the inside and outside of the bag pushes a little plastic into the mold. There is a lot of information describing this method vividly and visually. Its advantage is that vacuum bags can be reused.

4. Conclusion

In short, composite materials are one of the extremely ideal choices for a variety of manufacturing projects. Composite materials that complement each other in terms of properties of the component materials will give us optimal mechanical and chemical advantages. There are a variety of methods mentioned above, but to choose a suitable composite material processing method, we need to consider the plastic material and production needs. Read more meaningful articles from EuroPlas to have more options for your upcoming project!