In this article,

EuroPlas will provide readers with a wealth of knowledge about Polypropylene multi-purpose plastic material. From understanding the definition and composition to the diverse applications in daily life of Polypropylene, along with outstanding PP product lines.

EuroPlas is dedicated to equipping readers with the necessary information to be able to make smart decisions in the production and business process. Let's get started now!

1. What is PP plastic? – Composition and development history

PP plastic, commonly referred to as polypropylene plastic, is a thermoplastic polymer made from the monomer propylene and known as a versatile material with an excellent combination of various properties. PP plastic belongs to the category of olefin resins, which are heat-resistant polymers made from carbon and hydrogen compounds. The formula chemical of PP plastic made from monomer propylene is (C3H6)n, with n representing the number of monomer units present in the polymer chain.

What is PP plastic?

What is PP plastic?

The initial exploration of polypropylene took place in 1951 with the combined efforts of chemists John Paul Hogan and Robert Banks. Following this, Italian professor Giulio Natta successfully accomplished the first polymerization of polypropylene merely three years later. This groundbreaking achievement swiftly propelled polypropylene to emerge as a paramount polymer compound within the plastic industry.

In several years after, PP plastic was commercialized then immediately demonstrated its worth by rapidly gaining popularity as a widely used plastic material in Europe. According to Grand View Research, the global PP plastic market size is estimated to be US$123.46 billion by 2022 and anticipated to witness significant growth with a compound annual growth rate (CAGR) of 4.7% from 2023 to 2030.

2. The advantages and disadvantages of PP plastic

PP (Polypropylene) plastic is highly favored by numerous businesses in various industries due to its exceptional properties and advantages. Gaining a comprehensive understanding of its features will enable manufacturers to maximize its benefits, streamline production processes, and reduce unnecessary expenses.

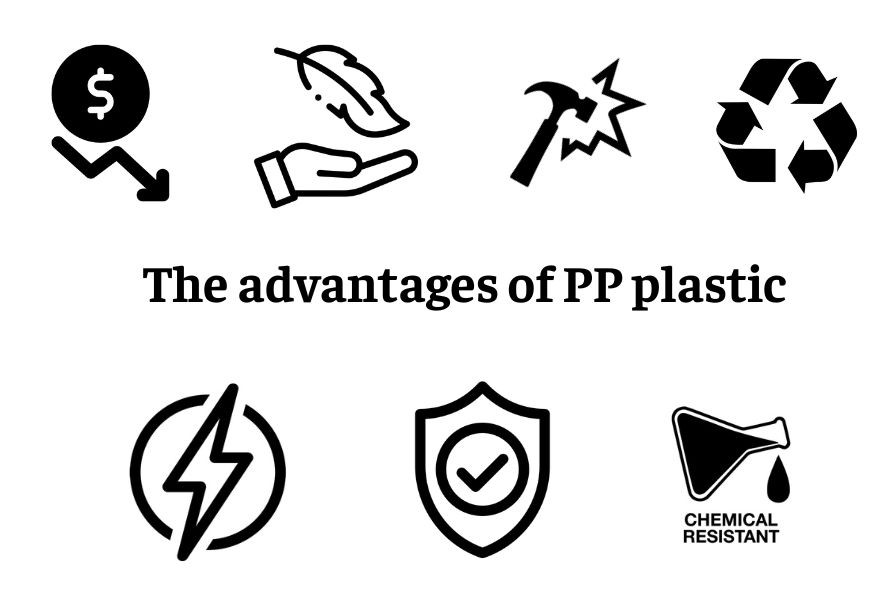

The advantages of PP plastic

The advantages of PP plastic

| Advantages |

Disadvantages |

- High durability

- Resistant to chemicals and most organic solvents

- General impact and mechanical impact resistance

- Electrical insulation

- Light-weight

- Recyclable

- Low cost |

- Limited use in high temperature

- Non U-V resistance

- Difficult to bond with other materials such as paint or glue

- Mining process can affect the environment

- Non-biodegradable |

Nevertheless, while PP plastic offers significant benefits, it also possesses certain drawbacks. One of them is that PP plastic is not easily degraded in the natural environment over time due to its durability, chemical resistance, and waterproofing ability.

3. The applications of PP plastic

The applications of PP plastic

The applications of PP plastic

- PP (Polypropylene) plastic is a versatile material that finds applications in various fields. Below are some typical uses of PP plastic:

- Household items: PP plastic is used to make water bottles, food storage boxes, plastic cups, food wrapping bags, and spice jars, among others.

- Packaging and transportation: PP plastic sheets are employed in the production of containers for goods, product bags, and other types of containers.

- Medical field: Many medical equipment, including urinary catheters, children's bathtub blood tubes, epoxy gaskets, and numerous other products, are made from PP plastic due to its acid, corrosion, and chemical resistance properties.

- Automotive industry: PP plastic is utilized in the manufacturing of automotive parts such as headlights, lamp covers, and spare parts holders.

- Electronics industry: PP plastic is used for producing cases, cell phone cases, computer tubes and screws, and electronic systems.

- Agriculture field: PP plastic can be used to make netting, crop protection film, fertilizer packaging, and other agricultural products.

4. Types of PP plastic

Primary PP plastic is a polypropylene polymer resin derived from petroleum-based raw materials. It possesses excellent qualities such as high heat resistance, resistance to abrasion and chemicals, as well as exceptional durability. This type of plastic is widely used across various industries including packaging, automotive, and electronics.

Recycled PP plastic is reused from previously used PP plastic products. Recycling PP helps mitigate plastic waste and conserves resources, although it may exhibit slightly inferior properties compared to virgin PP. However, continuous advancements in recycling technology are making recycled PP plastic a more sustainable and environmentally friendly option.

Scraps PP plastic is the waste, products, or fragments of Polypropylene plastic that have been used and are no longer usable. Typically, recycled PP plastic is collected, separated, and sent to recycling plants to be processed and transformed into recycled plastic materials. The process of recycling PP plastic helps reduce plastic waste, conserve resources, and minimize environmental impact. Recycled PP plastic products can be reused in various industries such as packaging, household appliances, and many other applications.

5. PP products of European Plastic Company

PP Flame Retardant Compound

PP Flame Retardant Compound (PP-FR) is a mixture of polypropylene (PP) resin and halogen/non-halogen flame retardant. Adding halogen/halogen-free additives and reinforcing glass fiber makes PP compounds less flammable, with high performance and more desired mechanical properties. By using flame-retardant polypropylene, businesses can directly process without mixing other materials.

PP Conductive Compound

PP Conductive Compound is made of PP resin and carbon black conductive. Conductive polypropylene pellets are lightweight and simple to work with throughout the injection molding process. Therefore, it has many applications such as manufacturing electronic components, cable jackets, and electrical equipment housing.

PP BaSO4 Compound

PP BaSO4 Compound is polypropylene treated with BaSO4 to reduce shrinkage and deformation in high-temperature settings and enhance formability and heat, chemical, and impact resistance. These benefits make the PP BaSO4 compound perfect for usage in a range of applications where dimensional stability and durability are critical, such as producing sanitary equipment, house appliances, or water filter equipment.

PP Talc Compound

Talc is a natural mineral of magnesium, silicon, oxygen, and hydrogen (Mg3Si4O10(OH)2). Talc is ground into white powder before being mixed with other compounds, commonly known as talc powder form. PP talc compound consists of talc powder and appropriate additives such as dispersant and bonding additives according to end-product requirements. Using talc in thermoplastic helps increase stiffness, flexural modulus, and strength, reduce creep tendency in increasing temperature environments, and improve heat distortion temperature and dimensional stability.

PP Glass Bead Compound

PP Glass Bead Compound is a combination of PP resin, glass beads, and other additives. The advantages of glass beads are transparency, compressive resistance, and high thermal stability thanks to their spherical shape. In addition, glass bead reinforcement can also improve the mechanical stress under load.

PP Glass Fiber Compound

PP Glass Fiber Compound is made of PP base resin, glass fiber, and other additives. It gives the final products increased flexural modulus and tensile strength. With those high-performance properties, glass fiber-reinforced polypropylene delivers superior strength for furniture, electric appliances, and automobile applications.

At EuroPlas, we take pride in delivering top-notch plastic products that undergo meticulous processing for each component with exceptional precision. Our team of highly skilled experts is dedicated to providing unrivaled services, ensuring complete customer satisfaction.

Contact us today to explore our wide range of products and discover the ideal plastic solution tailored to your specific needs.

You can find additional valuable information right here!