Recycled plastic particles and primary plastic beads develop in parallel with bioplastic materials. They are widely used in many fields such as: Mechanical, electronics, automobiles, household appliances and so on. The basic way to differentiate between the two types of virgin and regenerated plastic beads is the characteristics, properties as well as price. If the recycled plastic beads will be a bit hard and tough when touched (held or grasped), the virgin plastic will be more elastic and flexible. Therefore, the price of virgin plastic will also be slightly higher. However, the differences between these two material lines are still many. In the article below, EuroPlas will provide detailed information about the advantages, disadvantages and detailed applications of each type in addition to their differences.

-v%C3%A0-nh%E1%BB%B1a-nguy%C3%AAn-sinh-(primary-plastic-beads)-ph%C3%A1t-tri%E1%BB%83n-song-h%C3%A0nh-c%C3%B9ng-v%E1%BB%9Bi-v%E1%BA%ADt-li%E1%BB%87u-nh%E1%BB%B1a-sinh-h%E1%BB%8Dc.jpg)

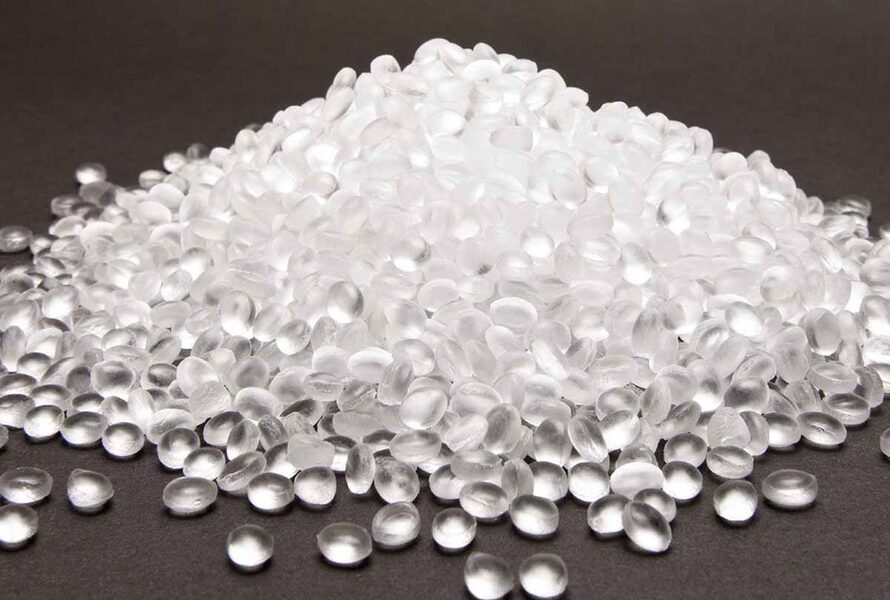

1. What are recycled plastic pellets and primary plastic pellets?

Recycled plastic pellets are produced from the repeated recycling of virgin plastic pellets or from the same material stream. For example: Plastic waste will be classified and go through the process of crushing, cleaning, heating and pressing into fibers to produce recycled plastic. Currently, recycled plastic pellets are divided into 5 common types, namely: HDPE recycled plastic pellets, PP, PE, PVC and ABS recycled plastic pellets.

The physical properties of recycled plastic will be stable and quite tough. In addition, recycled plastic from HDPE material can resist the impact of strong acids or salts, has a long service life and does not rust in humid environments. Because of the production stage and origin, recycled plastic is cheaper than virgin plastic.

In the opposite direction, virgin plastic beads are produced from long-term petroleum distillation. In particular, the original virgin plastic will be white. Therefore, manufacturers can combine additional color additives without affecting their chemical composition or physical structure. Basically, primary plastic beads have quite high elasticity combined with flexibility and the ability to adapt well to environmental temperatures.

That is why they are widely used in the medical field, food packaging production or other health-related fields. This proves that the price of virgin plastic beads is definitely higher than recycled plastic and may be slightly higher than bioplastic. Just like recycled plastic beads, primary plastics are also divided into many common types such as: PET, PP or ABS.

In addition, although the two plastic materials are different in physical and chemical properties, they can both combine well with plastic additives to improve characteristics and develop specialized features in each field.

2. Advantages and disadvantages of recycled plastic pellets

Recycled plastic resins play a role in the strategy of green economic development as well as environmental protection of the global plastic industry. Therefore, the advantages of this material line are many and diverse. As follows:

-

In general, recycled plastic pellets can be recycled many times, but the quality will also be slightly affected and the impurity content will likely gradually increase.

First, durability is the strong point of recycled plastic beads. Because they go through many stages in the production process from grinding, cleaning, melting to shaping.

Besides, price is also a decisive factor in the consumption and popularity of recycled plastic particles. Input materials for recycled plastic can be plastic waste, virgin plastic or other types of plastic. Therefore, they not only meet economic and profit criteria but also ensure environmental sustainability and stability.

-

In addition, recycled plastic pellets also have very good plasticity, typically like PE recycled plastic pellets. Therefore, they also possess quite stable tensile strength if subjected to force for a short period of time. PE recycled plastic pellets are often used in the field of food packaging and water blowing pipes production.

-

The next advantage of recycled plastic pellets is the ability to conduct electricity stably, such as PVC recycled plastic pellets. The resistivity coefficient of this material is greater than 1013 Ω.cm. Not only that, recycled plastic pellets are produced in many colors and sizes, and their flexibility in many fields is higher than virgin plastic pellets.

-

Recycled plastic resins not only have sustainable plasticity but also heat resistance. They are also highly appreciated for this advantage when they can withstand up to about 200 degrees Celsius. Therefore, this is also a suitable choice for heavy industries.

In the opposite direction, recycled plastic beads also have some weaknesses as follows:

Although it can be recycled many times, the yield and quality of the material will certainly be reduced and severely affected by impurities from the input fuel. Recycled plastic pellets have not very good durability, products made from this material will easily have surface scratches if they encounter strong impacts during use.

Depending on the different types of input plastic, specific weaknesses of recycled plastic granules in general will form. For example, PVC recycled plastic beads will be hard and quite brittle, they are not flexible like PE or PP plastic. Besides, ensuring the quality of input materials as well as the production process of recycled plastic pellets will take longer and more complicated than virgin plastic.

3. Advantages and disadvantages of virgin plastic beads

Unlike recycled plastic, primary plastic is distilled from petroleum fractions and undergoes a thorough filtering process. Virgin plastic pellets also bring many advantages to businesses and customers. As follows:

In general, virgin plastic beads have flexible properties, can withstand large curvatures and pressure if subjected to strong force for a long time. In addition, elasticity is also a perfect plus point for virgin plastic beads.

In particular, virgin plastic is only white immediately after production, but this has helped it increase its aesthetic value when it has a glossy, smooth surface and bright colors. To change the color according to market needs, manufacturers will combine color additives.

In addition, virgin plastic beads also have good durability and are easy to shape during the long-term production process. Therefore, their flexibility will also be higher than recycled plastic beads. For each different type of plastic, virgin plastic will also possess different advantages. Specific examples are:

-

PP virgin plastic beads are heat resistant between 1300 and 1700 degrees Celsius. In addition, virgin plastic will be odorless, colorless and extremely safe for consumers' health.

-

PA virgin plastic beads are capable of withstanding strong impacts for a long time. Not only stable heat resistance, this type of virgin plastic also has good chemical durability as well as stable electrical insulation. In particular, PA plastic in general and PA virgin plastic beads in particular can resist the intrusion of chemicals from the outside environment and are safe for food. Therefore, virgin plastic beads from PA plastic are commonly used in the field.

-

Or virgin plastic beads from ABS are commonly used in the electrical field because they are waterproof, have stable heat resistance and electrical insulating properties. In particular, virgin plastic is licensed to be used to create children's toys because they do not have a plastic smell or become deformed or discolored when exposed to high temperatures.

Besides the advantages, virgin plastic beads also have some disadvantages. First, virgin plastic beads are considered quite difficult to decompose after being discharged into the environment. Besides, if you use it incorrectly during production or use, it can lead to poisoning. Like other plastic materials, virgin plastic beads are also recommended not to be sucked or swallowed.

Because of the outstanding advantages of primary and recycled plastic beads, they are applied in many fields. Refer to the next section to learn about the practical applications of these two materials!

4. Application of 2 lines of virgin plastic beads and recycled plastic beads

After distinguishing between the properties of primary and recycled plastic pellets, EuroPlas sends you the wonderful applications of these two plastic lines in modern industry. Specific examples are as follows:

-

ABS virgin plastic beads are solid, not brittle, and are very good insulators of water and electricity. Furthermore, ABS virgin plastic is considered to have good surface hardness, capable of withstanding strong impacts during use. Therefore, they are used to produce regular helmets and insurance for professional riders. In addition, ABS virgin plastic is also used to produce chemical containers as well as motorbike accessories.

-

One of the popular types of virgin plastic beads is PP. They are transparent in color and are often combined with color-forming plastic additives. Compared to PE plastic material, PP plastic is quite hard, not flexible and not easily stretched into fibers. Besides, this type of virgin plastic beads is quite cheap, tasteless, non-toxic and odorless after long periods of use. Therefore, children's toys, plastic trays, and household items are popular products made from PP virgin plastic.

-

PA virgin plastic beads are also on this list. Because of their high technical properties, good toughness and stable force-resistant surface, they are widely used in the fields of automobiles, aviation and electronics. In particular, virgin plastic from PA can resist the penetration of parts from acids or strong chemicals and has a high antibacterial rate, so the medical industry is also very fond of this material.

On the other hand, recycled plastic pellets also contribute significantly to the plastic industry in general and heavy industries in particular. Specific examples are as follows:

-

HDPE recycled plastic beads have the ability to withstand heat up to more than 300 degrees Celsius and the ability to withstand heavy impacts for long periods of time. Because of its durable properties, HDPE does not oxidize or alkalize when exposed to strong acids. Therefore, HDPE recycled plastic pellets are used to produce bags, packaging, plastic cans, household appliances, bag blowing, and environmental products.

-

PP recycled plastic pellets are also equally popular. They have slightly hard physical properties, moderate toughness, high surface durability as well as a long product life cycle. Therefore, car interiors or laboratory items are typical products produced from recycled PP plastic beads.

-

Recycled plastic ABS (Acrylonitrile butadiene styrene) is a very flexible, impact-resistant plastic that is recycled from injection molding products, keyboards, office machines, car and motorbike parts, and hats. insurance, toys, light, hard, malleable products such as pipes, boxes, musical instruments, car fenders, spools, and are used to produce lower-grade products than the original product.

EuroPlas has sent you some practical applications of two types of recycled plastic pellets and virgin plastic pellets.

EuroPlas - The world's number 1 filler masterbatch manufacturer

EuroPlas is proud to be the world's largest filler masterbatch manufacturer. We are confident in providing specialized material solutions to help businesses improve their competitive advantage in many fields.

The entire EuP team always has the desire to elevate the Vietnamese brand on the world map, so a sharp mindset along with dedication and enthusiasm are indispensable factors. Most importantly, that is also the long-term goal and strategy that the EuroPlas board of directors is aiming for. It is that consistency that has created a sustainable development for EuroPlas

In particular, EuroPlas views each customer as an extremely important factor contributing to the overall success of the business, so the team is always careful and detailed in each material product.

Currently, with 7 factories with a scale of dozens of hectares in 6 provinces: Ha Nam, Yen Bai, Hai Phong, Nghe An, Long An and Ho Chi Minh City and a modern production line system, EuP's annual capacity reaches approximately approximately 0.8 million tons, ready to meet large quantity orders from all over the world. Currently, we are a regular partner of thousands of factories in more than 95 countries globally.

Conclusion

The above article has introduced in detail the difference between recycled plastic pellets and virgin plastic pellets. Please continue to follow EuroPlas to update the latest news on the global plastic materials market!