Talc filler masterbatch is undoubtedly one of the most common plastic fillers. Thanks to its outstanding mechanical characteristics, plastic talc filler has been widely used in many fields such as injection molding, extrusion molding, and blown film,... as well as providing end-products with multiple advantages.

Talc filler masterbatch is a well-known plastic filler. It is unexaggerated to say that the application of plastic fillers has revolutionized the plastic industry which once acknowledged the use of primary resins only. In particular, using plastic fillers helps plastic enterprises save a large amount of expense on input materials as most of them are at a relatively low price compared with primary plastic. Therefore, the plastic filler is an ideal alternative to a part of primary plastic. Besides, changing to plastic filler also minimizes the possibility of being negatively impacted by market fluctuation for plastic enterprises, thus paving the way for their sustainable development.

Among various types of fillers, talc may be one of the most preferable ones. This material can significantly reduce production costs while enhancing many properties of end-products such as thermal resistance, anti-block ability, and durability,... thus improving the competitiveness of plastic enterprises. So what is Talc filler masterbatch composed of? and how it is applied. Let’s discover with EuroPlas in this article below.

Read more: What is filler masterbatch and how it is applied to your production?

1. What is Talc filler masterbatch?

Talc filler masterbatch is a combination of talc powder, plastic resins, and necessary additives such as dispersant additives, bonding additives, and processing aid additives,... Depending on the end product’s requirements, manufacturers will choose the additives accordingly. As such, talc powder is nearly the key factor determining the mechanical properties of Talc filler masterbatch. So what’s special about this material?

This material is a combination of talc powder, plastic resins, and additives

This material is a combination of talc powder, plastic resins, and additives

Talc powder is a metamorphic mineral made of three main components: magie, silic, and oxy. In nature, this material exists in large reserves in the form of soapstone (a high-talc rock) and within whiteschist (for example the Franciscan Metamorphic Belt of the Western United States, the Western European Alps, certain areas of the Musgrave Block,...) and blueschist metamorphic terranes.

One special thing about this material is it’s a white soft odorless substance. Besides, it also has no chemical reaction when being directly applied to human skin, not to mention oil/moisture/smell absorption ability. Therefore, talc powder is an indispensable component in cosmetics production (skin cream, commonly used in cosmetic and pharmaceutical production. This characteristic also brings Talc filler masterbatch a high level of safety, thus making it an ideal choice for many food-contact end-products such as food packaging films, cutleries, and single-use dishes,...

2. Talc’s special properties

The reason why this material is widely used as Talc filler masterbatch lies in its outstanding properties:

-

High level of softness: talc is also known by another name - “soft stone” as this material’s rigidity is relatively low compared to that of others. This advantage allows plastic products containing talc to be printed easily on the surface, thus making talc the first priority in many fields such as sculpture, and household appliance production,...

Talc powder

Talc powder

- Inertness: unlike other substances which might cause allergy in humans when they have skin contact, talc powder is quite safe, making it an indispensable component in cosmetic production. Besides, this characteristic also gives talc filler a plus point when it is mixed with other matters as it hardly afflicts their properties.

- Processing aid: Seems a bit surprised but talc powder can assist in the processing procedure. Thanks to its low hardness, the processing of Talc filler masterbatch remarkably minimize abrasion on equipment than harder materials, especially in extrusion.

- Thermal resistance: Talc particle’s platy shape increases the heat resistance as well as reduces shrinkage, thus it is especially suitable for laboratory tabletop surfaces, sinks, and countertops. Also, this material enhances end-products’ rigidity such as polypropylene, vinyl, polyethylene, nylon, and polyester.

3. Common applications of Talc filler masterbatch

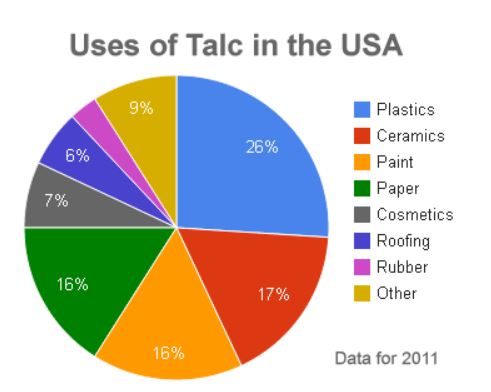

According to the United States Geological Survey, about 26% of talc produced in America goes to the manufacturing of Talc filler masterbatch, making it the largest contributor to talc consumption. That figure, once again, showed a rising trend in using talc as a vital plastic filler.

Talc filler is the largest contributor to talc powder consumption in the U.S Talc filler provides end-products with various outstanding mechanical properties such as thermal resistance, rigidity, anti-block, abrasion, and shrinkage decrease,...Specifically, the use of talc filler doesn’t require any changes in equipment and technology as it can easily meet all requirements of traditional technology methods. Another reason for the proliferation of talc filler roots in their reasonable price compared to primary plastic. Therefore, the use of talc filler more or less helps enterprises save a significant amount of input materials expense, thus giving end-products an advantage.

Talc filler is the largest contributor to talc powder consumption in the U.S Talc filler provides end-products with various outstanding mechanical properties such as thermal resistance, rigidity, anti-block, abrasion, and shrinkage decrease,...Specifically, the use of talc filler doesn’t require any changes in equipment and technology as it can easily meet all requirements of traditional technology methods. Another reason for the proliferation of talc filler roots in their reasonable price compared to primary plastic. Therefore, the use of talc filler more or less helps enterprises save a significant amount of input materials expense, thus giving end-products an advantage.

Thanks to its outstanding mechanical properties, talc filler is widely used in many fields.3.1. Blown films

Talc filler masterbatch is an indispensable component of packaging films such as shopping bags, food packaging films, single-use food boxes, and waste bags,... Its perfect white color, heat resistance, and glossiness have created end-products that perfectly meet all technical requirements. Besides, its components also make it a safe choice for end-users.

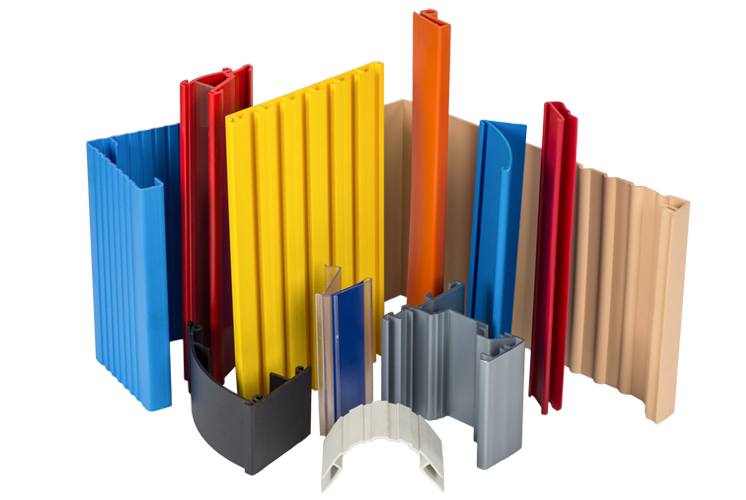

3.2. Extruded products

Another common application of Talc filler masterbatch is definitely extrusion with various products such as pipes, blinds, clear compounds, fencing, interior profiles, planks, and sheets. The use of talc has made them harder, more stable, and more endurable. Besides, the softness of this material also streamlines the process of end-products as well as minimizes negative effects on equipment.

3.3. Injection molding products

Injection molding products such as glass, plates, bowls, knives, forks, and spoons,...also use talc filler as an important filler for enhancing stiffness, thermal resistance, and durability.

3.4. Raffia

Woven bags, non-woven cloth, and elastic membranes,...are other popular applications of talc filler. Thanks to the use of talc, end products are reinforced with better heat resistance, rigidity, and durability.

4. Talc filler masterbatch brand EuroPlas

More than 15 years of development, EuroPlas filler masterbatch has now been available in over 80 countries. Our Talc filler masterbatch is the perfect combination of high-quality talc powder, plastic resins, and other special additives to serve different customers’ requirements. With state-of-the-art technology, experienced engineers, and enthusiastic staff, EuroPlas is ready to meet all of your standards and even goes beyond your expectation.

For more information and consultation, contact us!