Filler masterbatch is widely applied in many aspects in the plastic industry. So what exactly is filler masterbatch and how is it applied into plastic manufacture? Let’s discover in the article below!

1. What is filler masterbatch?

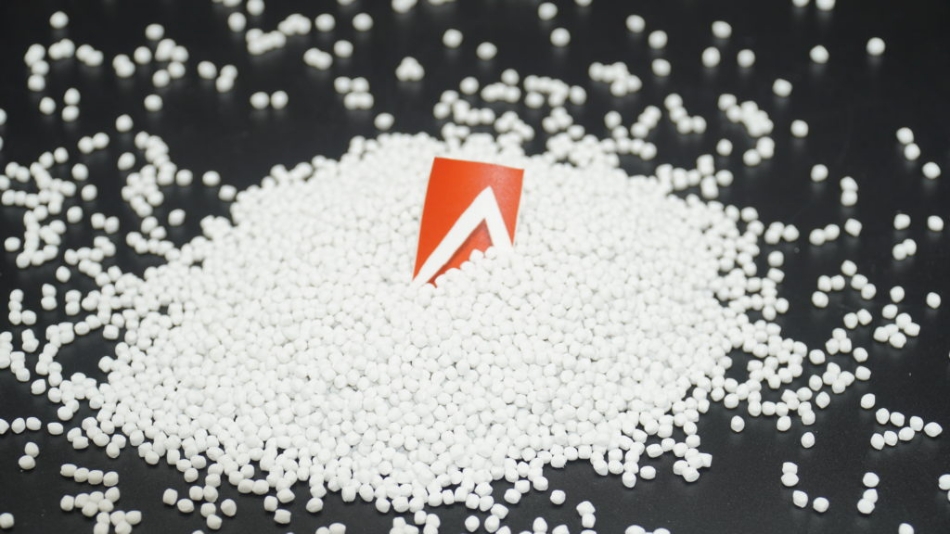

Filler masterbatch (also known as calcium carbonate filler) is amongst the most common plastic fillers. It is the combination of CaCO3, primary plastic resin and other special additives in accordance with customer’s demand. The production of filler masterbatch includes 4 steps:

Step 1: CaCO3, additives and plastic resin are mixed together by high-speed mixer.

Step 2: The mixture above is completely melted at high temperature.

Step 3: That mixture is then cooled and put into a screw extruder, pushed forward and pressed into the mold.

Step 4: The output of the extruder is cut into similar small pieces. They are filler masterbatch applied into plastic manufacture.

Production process of filler masterbatch

Production process of filler masterbatchRelated: Top 3 suppliers for you to buy plastic filler calcium carbonate

2. Why choose filler masterbatch?

First of all, primary plastic is made up of high molecular polymers, which are constituted of monomers. To create primary plastic, humans combine natural components including cellulose, rubber,... or Ethin, Benzol, Ethene gas, and most importantly - kerosene together.

Read more: What is plastic? Everything you need to know about plastic

Thus, using 100% primary plastic in plastic manufacture has the following disadvantages:

- Firstly, primary plastic is non eco-friendly. It takes hundreds of years for products made of primary plastic to be completely decomposed under natural conditions.

- Secondly, kerosene - the main component of primary plastic largely depends on foreign suppliers, which ends up with a relatively high price of finished products. Besides, due to the instability of kerosene supply, primary plastic is easily influenced by negative effects of foreign market.

Filler masterbatch enhances your product's quality

Filler masterbatch enhances your product's quality

- Thirdly, kerosene is a non-renewable resource, thus contributing to the unsustainable and unstable development of firms which takes kerosene as the main input material.

With a view to providing customers with an appropriate solution to address the root of the production expense problem, filler masterbatch was born.

Related:

Top 3 industries that benefit most from filler masterbatch

3. How it benefits plastic products?

So, how exactly plastic firms benefit from filler masterbatch?

- Product’s cost decrease: One of the main components of filler masterbatch is CaCO3, which is famous for its rich and high-quality reserve worldwide. This will definitely reduce production cost, stabilize the amount of input materials and significantly improve product’s competitiveness.

- Physical properties enhancement: Rigidity and plasticity increase, shrinkage decrease.

Filler masterbatch is widely applied in many products

Filler masterbatch is widely applied in many products

- Flexible applications: Thanks to the suitable toughness and stable chemical properties, filler masterbatch can be easily cut into small pieces or crushed into powder. It can also be mixed with other plastic resin to create new products with more functionalities.

- Forming enhancement: Filler masterbatch plays a vital role in adequate heat distribution in blow film or raffia, thus getting rid of bubbles on plastic surface situations.

4. What are filler masterbatch's applications in the plastic industry?

Thanks to its outstanding advantages regarding functionality and price, filler masterbatch has been widely applied into many industries.

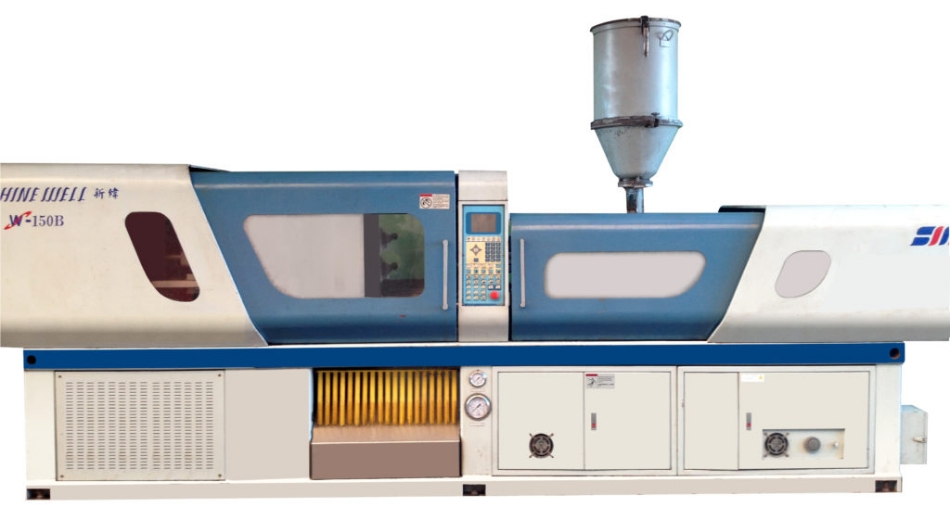

4.1. Injection molding

Injection molding is a common technology based on two main phases: extruding melted plastic mixture and pressing it into the mold for forming. This method is used to create many plastic products including rice cooker lid, toilet lid, buckets, baskets, boxes, toothbrush, plastic toys,...

Filler masterbatch has been applied in injection molding

Filler masterbatch has been applied in injection moldingWith filler masterbatch, the injection molding products have these following advantages:

- Manufacturing lead time decrease due to the good thermal conductivity of CaCO3.

- Input material expenses reduce thanks to the reasonable price of CaCO3, which is significantly more economical than primary plastic.

- Energy saving due to the decrease of manufacturing lead time.

- Stability increase during the product forming process.

- Carbon footprint decrease thanks to the replacement of primary plastic with CaCO3.

- Product’s physical properties increase (flexibility, rigidity,...)

- Product’s tear resistance increase regardless of its thickness.

- Product’s printability increase.

4.2. Extrusion

One of the most popular plastic manufacturing methods is extrusion. After being mixed together, input materials go into the extruder through the hopper. This combination is then melted under extremely high temperature and extruded by a mould clamping cylinder in the form of fibers. The cross section of these depends on the form of the mould clamping cylinder (commonly square or round).

Filler masterbatch has been applied in extrusion

The plastic fibers are then cooled by water or fan on the assembly line and cut into small pieces for packaging.

Extrusion is a common method to produce plastic products such as PVC pipes, straws, gutters,... thanks to its simple technology.

The application of filler masterbatch into extrusion helps:

- Reduce production cost thanks to the reasonable price of CaCO3 compared to primary plastic, thus decreasing product’s price and driving competitiveness.

- Enhance rigidity and Cải thiện độ cứng và khả năng chịu lực cho thành phẩm.

4.3. Blown film

Blown film is a common plastic manufacturing technology, especially in producing packaging (thin-film packaging, biodegradable packaging, paper packaging, packaging roll film, waste packaging,...). To create packaging film, materials mixture enters the extruder through the hopper. After being melted, it goes through an annular slit die and is formed as a thin tube. The tube is then cooled by the air ring and continues moving upwards until it passes through nip rolls, where it is flattened. This lay-flat tube is then taken back down via more rollers. The edges of the lay-flat are slit off to produce two flat film sheets and wound up onto reels.

Filler masterbatch is used in blown film

Filler masterbatch is used in blown filmFiller masterbatch is used in blown film to improve the rigidity, control heat, enhance the turbidity and most importantly, cut production expense.

Relating: Filler masterbatch and 4 most well-known applications

5. EuroPlas filler masterbatch

Thanks to its advantages, filler masterbatch has been widely applied in many fields with a view to optimizing production cost and to enhancing product’s competitiveness as well.

After 13 years of establishment, EuroPlas filler masterbatch has become the top-of-mind filler masterbatch manufacturer all over the world. We take pride in providing products for thousands of clients ranging from Asia, Middle East and North Africa to Europe.

EuroPlas filler masterbatch is applied in many plastic fields

EuroPlas filler masterbatch is applied in many plastic fieldsOur most popular products including:

- PP filler masterbatch: the combination of PP resin, high-quality CaCO3 and additives.

- PE filler masterbatch: is produced with PE resin, high-quality CaCO3 and additives.

- PS filler masterbatch: the mixture of PS resin, CaCO3 and other additives.

- BiOMates: includes bio plastic, CaCO3 and other additives.

For further information and samples, please contact us HERE!