PEF material (Polyethylene Furanoate) is becoming a sustainable alternative to traditional plastic. Since it's made from renewable plant-based resources, the material decreases the reliance on fossil fuels and reduces plastic waste.

The plastic's unique combination of high barrier properties, mechanical strength, transparency, and biodegradability makes it particularly suitable for food, beverage, and other consumer product packaging.

Polyethylene Furanoate PEF

Let's explore the applications of PEF material in packaging and what advantages this green solution brings to consumers and the environment!

Read more: What is Polyethylene Furanoate? PEF Market Trends

1. Top Applications of PEF in Packaging

PEF material is used in the following packaging applications:

- Bottles and containers: Bottles for water, juices, and carbonated drinks are some examples of PEF usage. The material's high barrier properties help retain carbonation and extend the shelf life of these beverage bottles.

- Food packaging: PEF material is suitable for both fresh and dry foods. The high barrier to oxygen and moisture is key to maintaining the product's freshness and shelf life.

- Flexible films: Similarly, films made from PEF material protect against oxygen and moisture, keeping processed meat, snacks, and cheese fresh.

- Cosmetic packaging: PEF offers clearance and aesthetic appeal to beauty products.

PEF material for cosmetic packaging

2. Key Properties of PEF Material

PEF material offers various outstanding properties, including:

- Excellent gas barrier performance

With a gas permeability of 0.5-2, PEF performs better than PET in terms of gas barrier performance. It preserves food freshness and prolongs shelf life by retaining carbon dioxide in carbonated beverages 5–10 times better than PET. PEF has the potential to replace PET, glass, or aluminum in applications such as soft drinks, water, alcoholic beverages, and juice bottles.

- Outstanding rigidity and transparency

PEF possesses a high degree of transparency and rigidity. PEF is 1.5–2 times stiffer than PET, with a tensile modulus (MPa) of around 3000–4000 compared to 2000–3000 for PET. Because of this, it's a great option for applications that need high transparency.

- Good thermal stability and mechanical strength

PEF material is a bio-based plastic that is perfect for heat-sensitive packaging applications because of its exceptional thermal resilience. Its mechanical strength, including good tensile strength, impact resistance, and flexibility, makes it durable and less prone to breakage during transport and handling.

Made from maize, wheat, or beet sugars, PEF plastic is a reusable polymer that is entirely plant-based. Since it does not need fossil fuel as a resource, PEF material offers great sustainability and benefits to the environment.

- Recyclability and biodegradability

PEF may be combined with PET without sorting, making it a highly recyclable material that can be recycled chemically or mechanically. With the right treatment, it may also become biodegradable. Their plant-based polymer degrades in the natural environment 100 times quicker than PET, outpacing conventional plastics. Plus, PEF containers can help reduce waste by extending the shelf life of food.

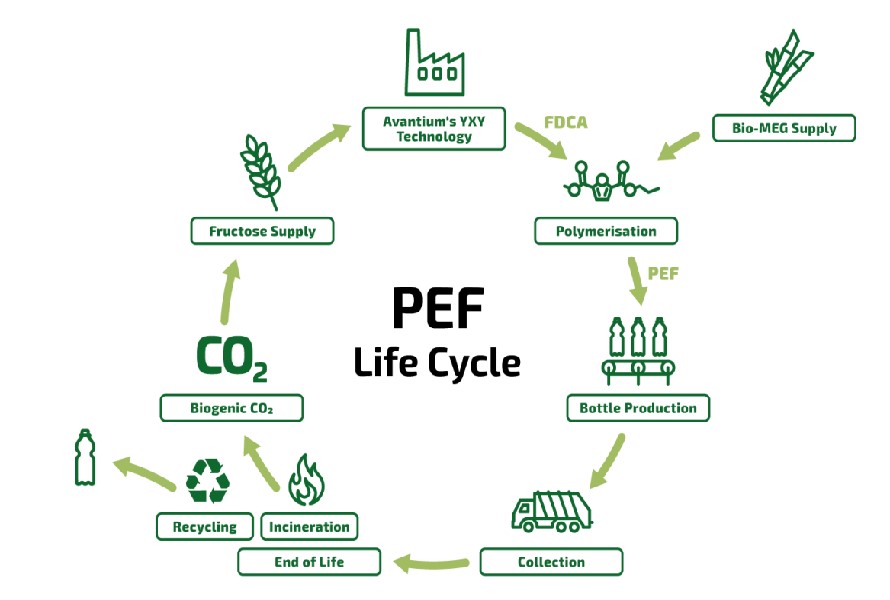

Life cycle of PEF material

3. Advantages of Using PEF in Packaging

Using PEF material in packaging brings lots of benefits for people and the environment. The key advantages are:

As mentioned above, the material's superior barrier properties protect food and beverages from oxygen and moisture, keeping them fresh and extending shelf life.

The transparency property of PEF material allows consumers to see the content of the products inside. It's especially useful for food and cosmetic products.

- Improved product protection

The mechanical strength and barrier properties benefit the product's protection. Products remain intact and fresh during transport and storage.

PEF material is made from renewable, biodegradable resources, reducing the reliance on fossil fuels and minimizing plastic pollution. It's considered a more sustainable alternative to traditional plastics since the material is recyclable.

PEF is a sustainable material

Compared to petroleum-based materials, PEF plastics create less carbon footprint to the environment. Its productions also release fewer greenhouse gas emissions since it's sourced from sustainably farmed crops.

- Recyclability and compostability

Because PEF is biodegradable and can be composted in industrial composting facilities, it is easily recycled in PET systems already in place, reducing landfill waste at the end of its useful life.

4. Conclusion

PEF material can transform the packing industry. Its versatility, strength, and environmental benefits are undeniable, shifting the choice of manufacturers who pursue sustainable development. The adoption of PEF will likely continue to grow, offering a cleaner, greener alternative to traditional packaging materials.

5. About EuroPlas

EuroPlas shares the same vision with sustainable development pursuers. As one of the leaders in the masterbatch world, we invest in modern technology to create eco-friendly solutions for manufacturers.

BioNext from EuroPlas

Our bioplastic compound and bio-filler are green materials, offering outstanding mechanical and aesthetic properties, biodegradability, and cost efficiency. They are suitable for the production of biodegradable packaging, injection molding, and single-use plastic extrusion products.

Contact us now for more details!