PEF resin is an ideal choice for the packaging industry with its superior sustainability and biodegradability. Its freshness retention, moisture resistance, and reduced carbon footprint make it a great eco-friendly packaging solution. With businesses looking to replace their current methods with greener options, PEF stands out as the most revolutionary solution among them. Read on to discover the top applications of PEF and learn how PEF is shaping the future of sustainable packaging!

1. Top Applications of PEF Resin in Packaging Industry

PEF resin has emerged as a sustainable and high-performance material for the packaging industry with its impressive properties. Thanks to that, the packaging industry can enhance product protection, extend shelf life and reduce environmental impact. Here are some of the top applications of PEF resin:

1.1. Beverage Bottles

PEF resin can be produced beverage bottles with a long-standing shelf life

With PEF resin, manufacturers can have a perfect material selection for beverage bottles made. Its excellent gas barrier properties include oxygen and carbon dioxide for beverages such as carbonated drinks, juice, and water, giving it a long-standing shelf life. Selected by leading beverage companies, bottle type PEF is replacing the traditional plastic bottles now available in the market.

Read more: What is Polyethylene Furanoate? PEF Market Trends

1.2. Food Containers

PEF resin has improved consumer happiness because of limiting wasting food

PEF resin is moisture and gas blocking, so packaging food retains both its freshness and flavor. The premade meals, snacks, and even packed frozen foods will keep fresh for a long time without going beyond the limits of creating food waste. Thereby, the manufacturer has improved consumer happiness because of limiting wasting food.

1.3. Cosmetics Packaging

PEF resin is quite strong with respect to light, air, and moisture

Luxury cosmetic brands are increasingly using PEF resin for bottles and containers. This is because PEF resin is strong with respect to light, air, and moisture. All of these properties are perfect for sensitive products such as creams, serums, and perfumes. Moreover, the material also provides a very durable and glossy finish to enhance packaging appearance.

1.4. Pharmaceutical Package

PEF resin meets requirements of the strictest environmental control, durability, and safety to human health

The PEF resin is an ideal choice in the pharmaceutical industry because it prevents oxygen access and enhances product stability. It matches the packaging of granules, capsules, tablets, and liquid treatments. Most applications in this field require the strictest environmental control, durability, and safety to human health.

1.5. Packaging Films

PEF resin possesses good tensile strength, is durable, and is a remarkable barrier for gases

PEF resin is currently proving to be outstanding and perfect in the definition of flexible packaging films. It is mainly because it possesses good tensile strength, is durable, and is a remarkable barrier for gases. These films are mainly applied to cover food that go bad quickly, such as beef, cheese, and vegetables, prolonging their lives and preventing spoilage.

1.6. Coffee and Tea Packaging

PEF resin can offer premium packaging solutions that keep coffee and tea fresh and of quality

In coffee and tea packaging, it is strictly required to keep the original flavor for consumers. PEF is an ideal packaging option for this type since it offers a wonderful oxygen and moisture barrier. These requirements are very necessary to avoid flavor and aroma deterioration of the products contained. It is evaluated that PEF resin can offer premium packaging solutions that keep these popular beverages fresh and of quality.

1.7. Containers for Alcoholic Beverages

PEF resin can be used with great effect in portraying products while safeguarding the quality over time

PEF resin containers can be used for wine, beer, and spirit drinks as a barrier against oxygen and for flavor loss. Due to its transparency, it can be used with great effect in portraying products while safeguarding the quality over time. Besides, to meet the requirement of many people choosing alcoholic beverages as a gift, PEF resin also provides a very attractive and glossy finish, making a great sense of luxury.

1.8. Sustainable Packaging Innovations

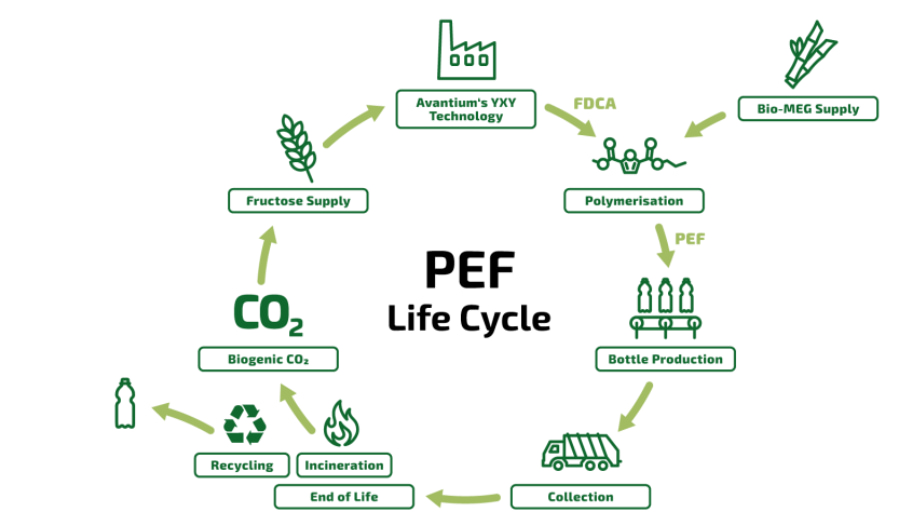

PEF resin will be among the key materials in developing eco-conscious products

In a context where people are increasingly raising awareness about environmental protection, PEF resin is a solution that cannot be missed. Innovative packaging solutions such as the biodegradable and the compostable can be made from PEF resin. This material does have a renewable bio-based origin that can be easily associated with sustainability goals. Thus, it will be among the key materials in developing eco-conscious products.

2. Challenges in Adopting PEF Resin for Packaging

While PEF resin offers great promise for the packaging industry, there are a number of challenges that are hindering its widespread adoption. Addressing these challenges is essential to ensuring the successful integration of PEF resin into modern packaging solutions. Let’s take a closer look at some of the common challenges below:

Most recyclers rarely accept PEF resin because they do not have a suitable recycling stream

2.2. Consumer Awareness

Currently, despite the widespread presence of PEF in the market with high frequency, information about their environmental friendliness is not widely disseminated to consumers. Clear communication will help customers better understand the benefits, features, and importance of packaging made from PEF resin.

To address this challenge, manufacturers can implement marketing and advertising campaigns to convey the benefits of PEF resin to customers. This action will help raise awareness among buyers and enhance the value of the product and the reputation of the brand in general.

2.2. Limited Recycling Equipment

Compared to other common plastics such as PET, PEF resin has a rather limited recycling method in the materials industry. In fact, there is a gap in infrastructure and recycling equipment for this type of plastic compared to other recycled plastics. For example, most recyclers rarely accept PEF resin because they do not have a suitable recycling stream. This makes PEF resin’s mission of managing plastic waste and building sustainable materials quite difficult.

One of the most effective solutions to this challenge is to raise public awareness of PEF resin as an environmentally friendly plastic. This, combined with the expansion of recycling facilities, can help integrate PEF into a more common recycling stream.

3. Future Outlook for PEF Resin in Packaging

The application of PEF resin in the packaging industry shows promising potential for sustainable growth. Following are some positive prospects that highlight its future potential:

Further opening market opportunities for PEF resins in food and beverage packaging

3.1. Expanding Biodegradable Packaging Markets.

PEF resin is set to drastically change the face of the green packaging industry because it is biodegradable. With companies under increasing pressure from the tightening environmental regulations, they will soon make investments in biodegradable materials, further opening market opportunities for PEF resins in food and beverage packaging.

3.2. Increased Adoption by Global Brands

Global brands have begun transferring from traditional packaging to sustainable packaging to attract eco-friendly consumers. As more companies commit to becoming carbon-neutral, this gives PEF one of its most important advantages over other materials because of raw materials from renewable sources and better performances.

3.3. Technology Advancements in Manufacturing

Improved production techniques will add scalability and cost-effectiveness to PEF resin technologies. Development in technology will also mean more energy efficiency during manufacturing processes, which will cause a reduction in the cost of producing PEF resin and will make them more competitive with other conventional plastics.

3.4. Further Recycling

The future developments in recycling infrastructure will leave an open door for the immersion of PEF resin into the circular economy. Due to advances that have been made in recycling technology, PEF products can now be collected, processed, and reused without creating a significant environmental impact.

4. Conclusion

PEF resins have recently been considered as a new breakthrough material in the revolution of the packaging industry. They stand out for their superior performance and flexibility, sustainability and environmental friendliness. The applications of PEF are almost covering areas such as beverage bottles, food containers, cosmetic packaging and pharmaceutical packaging, proving the potential of the material. At the same time, information about the benefits of PEF resins still needs to be promoted in order to be widely disseminated, which will help solve existing challenges and increase customer choice.

There is a favorable future for PEF resins, with expectations of increased production and better integration into recycling operations. With the increasing demand for green materials, PEF resins are indeed one of the key components shaping a sustainable and efficient packaging industry.

5. About EuroPlas

EuroPlas is proud to be the world's leading supplier of high-quality plastic materials. EuroPlas products are a range of innovative material solutions designed for applications that require excellent performance and sustainability. Our team of experts constantly research and develop to create custom material formulations that ensure optimal performance for each project.

We are proud to offer a product range that perfectly meets diverse industrial needs. EuroPlas ensures that our product processes are always strictly controlled to meet all high standard requirements. Contact EuroPlas today to get the best advice for your upcoming project!