TPO material, or thermoplastic polyolefin , is an upgraded version of the regular PP grades in terms of light weight, ease of manufacturing, and improved ductility, impact resistance and chemical resistance.

This subfamily of thermoplastic elastomers has excellent properties of exterior and interior automotive applications, roofing, as well as industrial liners.

Our article will tell you more about its weak and strong points and inform you what can replace Let's delve into the details right now!

Read more: TPO Plastic: Everything you need to know

1. Advantages of TPO Material

1.1. Excellent Mechanical Strength

TPO material is known for its exceptional mechanical strength. It’s usually an ideal choice for intensive applications because of its great impact resistance.

TPO is abrasion-resistant and suitable for most environmental challenges and. The material can also easily be wrapped around pointy features and fit over complicated geometries thanks to its exceptional pliability.

1.2. Improved UV Protection

The versatility of TPO material allows it to withstand a range of severe environmental conditions, including UV radiation. TPO provides UV protection, and with the use of additive packages, it stops color fading over time.

Thanks to these developments in polymer technology, TPO is a perfect fit for outdoor components. Additive packages can also be introduced during the extrusion process to increase the material's longevity.

1.3. Great Temperature Resistance

TPO meets a need for weatherability and durability. It combines stiffness, cold-impact resistance, and low thermal expansion.

It’s popular in the automotive and industrial applications where it resists heat and cold, retains its shape, and has restricted capability to expand or contract because of heat.

Automotive makers are progressively switching from traditional metal materials to TPO to prevent issues like swelling and breaking bumpers during hot summer days. As a result, TPOs are being chosen as new materials to ensure the lifespan and long-term performance of automobile components.

1.4. Compatibility With Chemical

Polypropylene (PP) is a chemically stable substance that can resist various organic and inorganic compounds. This compatibility is improved by TPO coating, making it possible to use this material in any temperature range as its performance does not degrade significantly. Because of this, PP is employed in the lining of wastewater reservoirs, water containers, and landfill infrastructures.

1.5. Cost-efficiency

TPO material is more mechanical and chemical resistant than the conventional materials and it is not difficult or expensive to process. It is less expensive and has good manufacturability.

It can be manufactured through blow molding or extrusion methods, or perhaps even injection molding. TPO material also eliminates the need for drying before molding, considerably lowering expenses.

1.6. Eco-friendly

The use of thermoplastics is increasingly under pressure from many regions around the world to be green and as clean as possible and this has led to rising focus on the sustainability of the material used to produce these thermoplastics.

TPO-coated polypropylene is a durable, recyclable thermoplastic that may be used to make goods that last longer and cut down on the amount of plastic waste that ends up in the environment.

Thus, TPO material becomes an ideal option to help manufacturers limit permanent damage while pursuing profits.

2. Disadvantages of TPO Material

- Surface bonding difficulty: TPO surfaces pose challenges in bonding due to their non-polar nature and low surface energy. Manufacturers may need to use specific adhesives to create strong and long-lasting bonds.

- Limited color option: The material has fewer custom color and finish options, which may be disadvantageous in applications where aesthetics are crucial.

- Potential short life span in some applications: compared with other materials, lifespan of TPO may not be high when the material is under mechanical pressure and in extreme climatic conditions. This could possibly lead to premature cracking or failure and may require periodic renovations or replasters.

3. Applications of TPO Material

The properties of TPO are ideal for:

- Automotive parts: Impact resilience, paintability, and relatively low density make TPO a favorite material for the automotive industry external applications including wheel or hub covers, bumper fascias, or body side molding.

- Roofing: TPO roofing membranes are popular for application in both new construction and retrofit markets because of its ability to reflect heat and UV light, and for its range of flexibility.

- Geomembranes: TPO geomembranes provide waterproofing and environmental barriers to some constructions like , landfill system, pond liners and irrigation canals.

- Liners for pool and pond: Because TPO liners can withstand water, chemicals, and UV radiation without degrading, they are a reliable and waterproof solution for ponds, swimming pools, and other water features.

4. Conclusion

Despite the disadvantages, TPO material is a versatile choice with various advantages that are suitable for specific applications, especially roofing membranes and automotive components.

Before choosing the material for your products, consider the TPO's performance, cost-effectiveness, and longevity to make informed decisions.

5. About EuroPlas - Where you can find the best plastic materials

EuroPlas is known as a leader in the masterbatch field since the company satisfies a wide range of requirements for unique plastic raw material solutions to optimize production costs and improve the customers' competitiveness.

EuroPlas, a global producer and exporter of filler masterbatch, offers a range of products to help manufacturers save costs, enhance productivity, and produce high-quality plastic products.

EuroPlas, a global producer and exporter of filler masterbatch, offers a range of products to help manufacturers save costs, enhance productivity, and produce high-quality plastic products.

These masterbatches combine calcium carbonate, primary resin, and other additives to obtain advantages like reduced shrinkage, improved stiffness, bend strength, stability, printability, surface quality, and energy savings. They are suitable for injection molding, blow molding, PVC pipe manufacturing, packaging, plastic frames, and door production.

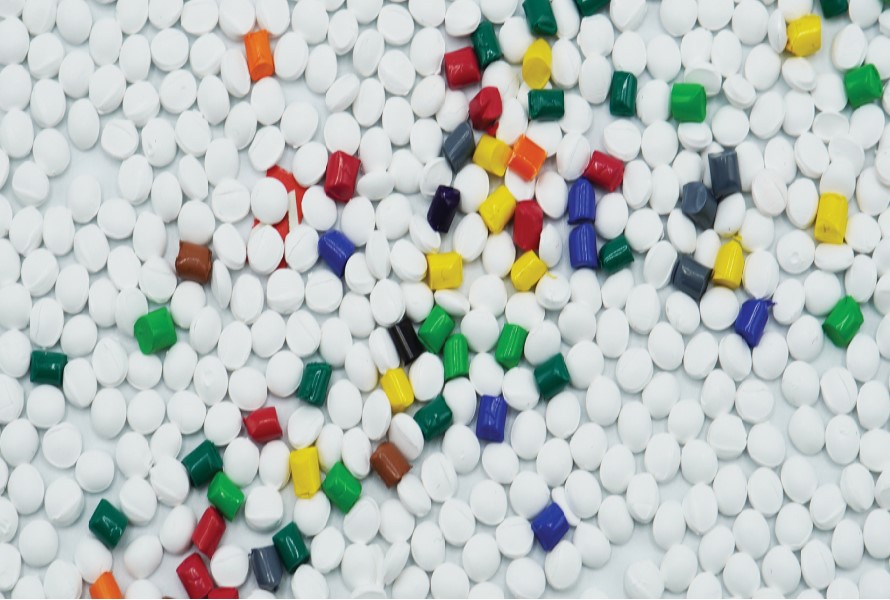

EuroPlas' color masterbatch is a high-quality solution for end-product aesthetics. It combines pigments, carrier resin, and additives to create colorful and attractive designs. It comes in a wide range of colors and effects, saves time and costs, and is environmentally friendly, allowing manufacturers to use it directly in production without harming the environment.

EuroPlas' color masterbatch is a high-quality solution for end-product aesthetics. It combines pigments, carrier resin, and additives to create colorful and attractive designs. It comes in a wide range of colors and effects, saves time and costs, and is environmentally friendly, allowing manufacturers to use it directly in production without harming the environment.

Plastic additives enhance the performance and durability of materials during production. EuroPlas offers a variety of additives for plastic, including flame retardants, desiccants, odor-removing additives, anti-UV, anti-aging, anti-fog, antistatic, anti-blocking, and processing-aid additives, enhancing the material's chemical and physical resistance.

Plastic additives enhance the performance and durability of materials during production. EuroPlas offers a variety of additives for plastic, including flame retardants, desiccants, odor-removing additives, anti-UV, anti-aging, anti-fog, antistatic, anti-blocking, and processing-aid additives, enhancing the material's chemical and physical resistance.

EuroPlas engineering plastic compound is a comprehensive solution for saving time and costs in various industries, including automobile, electronics manufacturing, interior decoration, and renewable energy.

EuroPlas engineering plastic compound is a comprehensive solution for saving time and costs in various industries, including automobile, electronics manufacturing, interior decoration, and renewable energy.

The compound consists of resin, additives, and reinforcements. We provide various products, such as PA6, PA66 blend compound, PBT GF-FR compound, ABS Glass fiber compound, ABS Antistatic compound, PC flame retardant compound, and ABS.

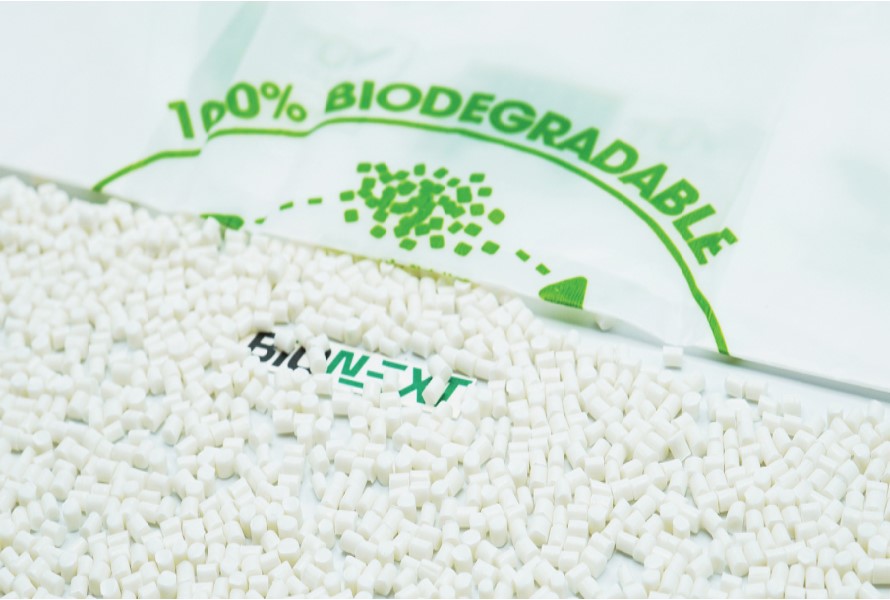

EuroPlas, a leading plastics company, is committed to sustainable development and environmental concerns. They produce high-quality bioplastic compounds for various industries, including automotive, construction, electronics, household appliances, and food packaging.

EuroPlas, a leading plastics company, is committed to sustainable development and environmental concerns. They produce high-quality bioplastic compounds for various industries, including automotive, construction, electronics, household appliances, and food packaging.

Our exclusive bio compound, BioNEXT, can decompose within 12 months and undergo rigorous quality control to meet all requirements. It's evident of our commitment to producing eco-friendly products.

Contact us now for more detail!