Thanks to the ever-changing technology, people now have several ways to process plastic materials like blown films, injection molding, extrusion, and thermoforming. Among them, plastic extrusion is one of the most popular processing methods because of its cost-effectiveness and flexibility. In this blog, we’ll explore what is plastic extrusion, 6 types of plastic extrusion, and its working process.

1. What is extrusion technology

Extrusion is a process of shaping materials using a die (a special shape). The material will be pushed through the die, and then the machine generates a new form of continuous objects. This technology is applied in a large number of industries like food, plastic, and metal production.

2. What is plastic extrusion

Plastic extrusion started centuries ago and now becomes one of the most popular plastic manufacturing methods. The plastic will be melted into liquid and pore into the dies so that it can be formed into a continuous profile. Depending on the die shapes, people use different plastic extrusion types to produce different products.

Plastic extrusion is a cost-effective solution thanks to its high capacity and low tooling cost. This method is extremely suitable for manufacturing plastic parts that have consistent wall thicknesses. Besides, it can also produce wider and longer profiles compared to those made by other processing methods. In daily life, it’s easy to find a lot of extrusion-produced items like plastic straws, plastic pipes, plastic sheets, and plastic profiles.

Source: https://bimetal.vn

3. Types of plastic extrusion

3.1. Blown film extrusion

This method is the best fit for producing food packages, shopping bags, and continuous sheeting. Granular pieces of plastic will be melted and cooled somewhat before leaving the die. From that moment on, the plastic turns into a semi-solid material. Then, air pressure will expand the semi-solid tube to the desired size and thickness.

3.2. Sheet/film extrusion

Sheet/film extrusion method is somewhat similar to the blown film method. However, because the end products must be thicker (when compared with products of blown film extrusion), instead of blowing the material, people will let the material go through a pulling and rolling process to get the desired shape.

When the rolling process, the plastic will be cooled down and solidified. We can find products made from this method in real life such as ice cream boxes, juice cartons, wine boxes, and other thicker plastic packaging.

3.3. Tubing extrusion

Tubing extrusion is perfect for producing long tubes, pipes, and other similar items. Generally, processing hollow equipment becomes more difficult. When the plastic reaches the die, the extruder will push a positive internal pressure throughout the material to create a hollow part.

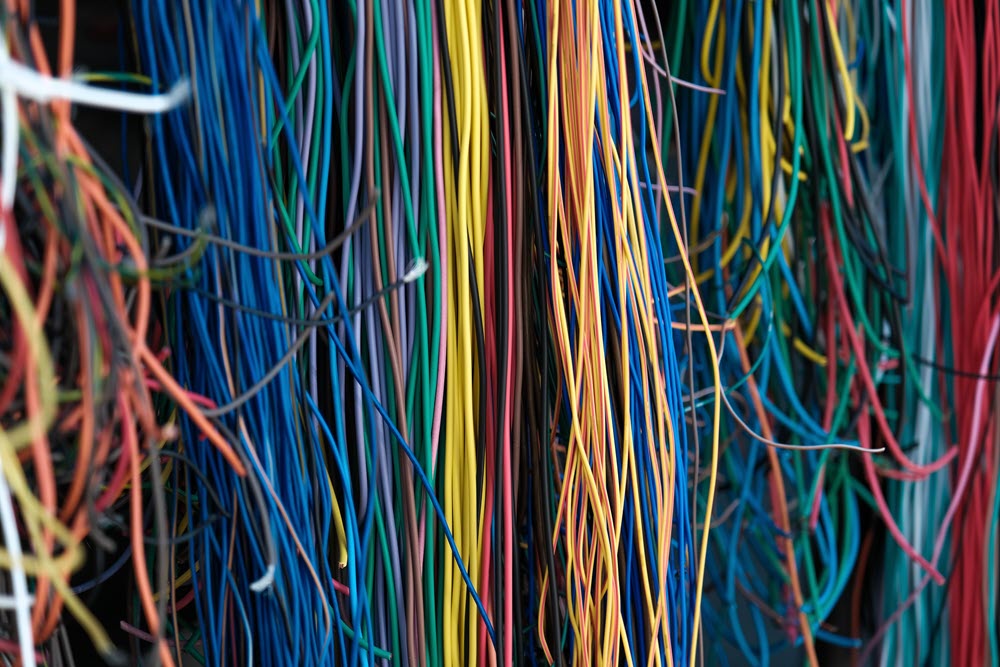

3.4. Over jacketing extrusion

If you are looking for a solution to cover something entirely with plastic, this method is exactly for you. As its name implies, in this process the machine will pull the material that needs the coating through the die to give it a plastic cover. To create an adhesion between the plastic and the material inside, we’ll use pressure tooling. An example of this method’s application is the plastic coating for electric wires.

3.5. Co-extrusion

Coextrusion is the utilization of 2 extruders to create the extrusion of multiple layers of material simultaneously. In this case, 2 extruders will melt and deliver plastic into a single extrusion head (die) which will extrude the materials in the desired form. The layer thicknesses are controlled by the relative speeds and sizes of the individual extruders delivering the materials. All methods described above (blown film, overjacketing, tubing, sheet) can apply this process.

3.6. Extrusion coating

To coat an additional layer onto existing products like paper, foil, or film, we’ll use extrusion coating to conduct the blown or cast film process. This method is perfect for improving the characteristics of paper by coating it with polyethylene to make it more resistant to water. The extruded layer can also be used as an adhesive to bring two other materials together.

4. Plastic extrusion process

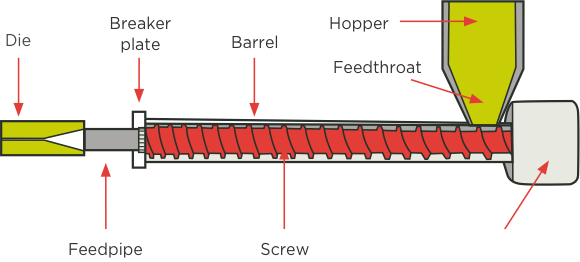

Before getting to know the plastic extrusion process, I think we should take a quick look at a plastic extruder. This image is an illustration of a plastic extruder, I’ll explain each parts of the machine right below.

4.1. What does a plastic extruder look like?

- Hopper: This is where people pore granular pieces of plastic into the extruder. It stores the plastic and prepares for the next process stage.

- Feedthroat: The feed throat is the part under the hopper. Here plastic goes from the hopper to the barrel.

- Breaker Plate: It’s like a filter for the barrel and helps maintain the pressure.

- Barrel: Its main duty is to soften the plastic and takes it close to the melting point.

- Rotating screw: It pushes the material to the feed pipe.

- Feed pipe: A pipe helping the molten plastic coming from the barrel.

- Die: This pushes the plastic to the desired shape.

- Cooling System: It’s used to solidify the plastic.

4.2. Plastic extrusion process

- Step 1: Fill in the hopper with a number of plastic pieces. The plastic will gradually go from the hopper to the feed throat and barrel.

- Step 2: The barrel then heated the materials using the three temperature intensity zones.

- Step 3: a continuously rotating screw on the barrel will push the molten plastic toward the next component of the machine.

- Step 4: Afterwards, the breaker plate will filter the liquid plastic. This screen helps remove other substances from the plastic and maintain internal pressure. Then, the liquid goes through a feed pipe before being poured into the die.

- Step 5: The die will constrain the molten liquid and shape it into the desired form.

- Step 6: When going out from the die, the extrusion product will be cooled in a water shower or cooling rolls to ensure that the shape will be permanent.

European Plastic Company (EuP) is a leading masterbatch manufacturer in Vietnam. We offer various materials for plastic extrusion technology for common applications, raffia, and non-woven fabric. If you are looking for a material solution for your plastic extrusion products, please don’t hesitate to contact us via email, and phone number ((+84) 24 3201 0358 ). You can also find us on Facebook, Youtube, and LinkedIn. We’d be more than glad to help!