Carbon black or black coal is one of the components that make up black masterbatch. Therefore, the indicators of their characteristics and properties can directly affect the quality of black masterbatch. Currently, N220, N330, S550 or S660 are popular types of carbon black on the market. In this article, EuroPlas will discuss the role, important indicators, impact on the product as well as the application of carbon black to black masterbatch. Don't miss it!

1. The role of carbon black in black masterbatch

Due to its excellent quality, carbon black is an excellent material that can be purchased and used in the production of black masterbatch. Carbon black has 4 core roles, specifically as follows:

-

Carbon black increases the adhesion as well as the stability of additives and virgin plastic to create black plastic particles. It is the adhesion of raw materials that creates the mechanical durability of black plastic particles. Therefore, they are used in the production of electronic equipment and auto parts.

-

Black plastic particles can be combined with many different superior additives because carbon black has the ability to mix and dissolve easily with most raw materials. Therefore, the basic properties of black plastic particles such as: UV resistance, anti-oxidation, etc. are also significantly improved.

-

In addition, carbon black plays an important role in saving production costs. Because carbon black is a popular raw material on the market and the production process of black plastic particles or color masterbatch is not too complicated. Therefore, manufacturers can save a lot of costs when producing in large quantities.

-

In addition, the stable electrical conductivity of carbon black will also directly support black plastic particles. That is why they become suitable raw materials for the production of electronic devices as well as ensuring safety during use.

-

Carbon black is outstanding in its ability to create black color for plastic materials or final products. Adding carbon black to colored plastic particles helps create good black color for plastic products, so it is an essential ingredient for many applications such as automobiles, insulating products and many other industrial applications.

.jpg)

Carbon black plays an important role in the production of black masterbatch

2. Important indicators of carbon black

Carbon black is a combination of 4 letters and numbers with the first character being: "N" or "S. Both represent the curing speed of a raw material mixture when not combined with carbon black. Specifically as follows:

-

"N": Normal, meaning normal curing speed, is a typical carbon black code of furnace technology (International name: Furnace Black).

-

"S": Slow, meaning slow curing speed. Their typical carbon black code belongs to soot coal produced by furnace technology.

-

After the characters "N" and "S", there will be the 2nd digit. They represent the average surface area of carbon black. Manufacturers use N2 (Nito) surface technology with ASTM 4820 testing method to determine the surface area.

-

The 3rd & 4th characters will be decided by the manufacturer to mark the details of the supplying units together. In particular, they will have a value 10 times that of the digit in the 2nd position.

.png)

Standard size measurements of black masterbatch

Besides those characters, the size of carbon black is also an important indicator to pay attention to. The size of the particles has a direct impact on the performance & quality of black masterbatch. In the plastics industry, particle sizes from 14nm to 90nm are commonly used.

Carbon black has a number of different applications due to particle size. Therefore, knowing the structure, porosity, physical shape and particle size is very important because these characteristics affect the performance of the product.

The properties and roles of carbon black are specifically expressed through meaningful indicators displayed on the packaging. Manufacturers as well as customers need to understand their detailed meanings to make the most suitable choice

3. The influence of indicators on product quality

The quality of black plastic products depends not only on the indexes but also on many other important factors, specifically as follows:

-

The size index will affect the dispersion of carbon black during the combination with virgin plastic. This will affect the color quality of black plastic and related products.

-

The surface area parameter of carbon black affects the hardness of the surface of black plastic products. Manufacturers can add additional plastic additives to strongly promote this advantage.

-

The curing speed index will also determine the quality of black plastic products. Because carbon black reduces the induction time and reduces the curing speed when the amount of surface acid groups on carbon black increases. The mechanism seems to be one of the competitive reactions between rubber and fillers to activate zinc oxide.

-

The temperature tolerance of black masterbatch ranges from 160 - 280 degrees Celsius. Therefore, products made from black masterbatch are applied in a variety of fields such as: Plastic pipes, automobile parts, electronic equipment, etc. The quality and life of the product are also significantly increased. Especially for products that are frequently exposed to heat or UV rays.

Carbon is applied in a variety of fields such as automobiles, packaging, electronics

4. Applications of carbon black

Carbon black is used in the production of black masterbatch. This is a variable material in the electronics industry. Basically, carbon black has the ability to resist and conduct electricity stably. Therefore, they can ensure safety during long-term use. In particular, black masterbatch minimize the problems of leakage or short circuits of electronic systems

Surface area indicators make carbon black a suitable filler in the production of car tires as well as other rubber products. Thanks to the ability to absorb heat and reduce thermal energy, black masterbatch increase the durability and stability of tires when they are rubbed against the road surface for a long time.

The small and uniform size of carbon black makes it easy to dissolve into virgin plastic materials. Therefore, the color of black masterbatch is significantly improved. Black packaging products are a typical example. The color and quality of black packaging is largely determined by the uniformity of carbon black.

Black plastic is commonly used in construction materials such as plastic pipes, insulation materials, roofing membranes. HDPE black plastic pipes are highly appreciated for their durability and resistance to chemical corrosion, making them suitable for water supply and drainage pipes. Black plastic sheets are also used for moisture resistance and as vapor barriers in walls and foundations.

In addition, the stable durability and small particle size indexes help carbon black to disperse well with raw material mixtures. Therefore, they are considered one of the perfect colorants. In addition, carbon black also contributes certain values to the current printing industry thanks to the above characteristics.

uroPlas's black masterbatch ensures the parameters as well as the quality of raw materials

5. Conclusion

EuroPlas has explained in detail the meaning of carbon black indicators in black masterbatch. Customers also have the opportunity to learn more about EuroPlas black plastic granules and their practical applications.

6. About EuroPlas black masterbatch products

EuroPlas is proud to be one of the prestigious manufacturers of filler masterbatch in the Vietnamese market. We provide a variety of plastic materials such as: Color masterbatch, compound engineering plastic, bioplastic. Black masterbatch is also one of the key product lines of EuroPlas.

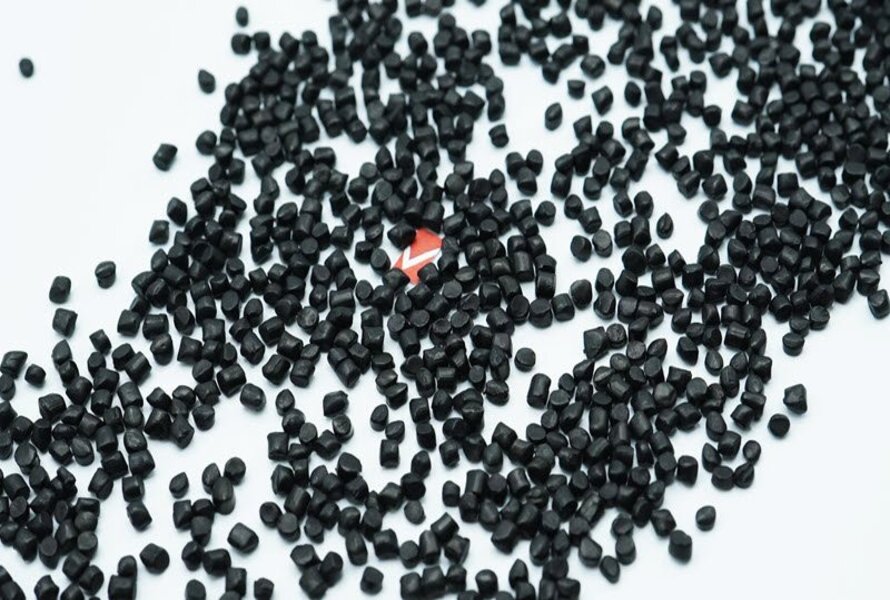

Black masterbatch at EuroPlas is produced from 3 main components: carbon black, virgin plastic and suitable additives. EuroPlas black masterbatch products possess 4 core advantages as follows:

-

Creating black color according to the requirements of the finished product

-

Good dispersion

-

High color fastness, good heat resistance

-

Contributing to improving the features of the final product such as UV resistance

A variety of color shades depending on customer requirements.

The heat resistance of carbon black helps increase the durability of products that are frequently exposed to high temperatures

In addition, EuroPlas also strictly inspects the specifications of black masterbatch products as follows:

-

Color: Black

-

Additives: Dispersants, processing aids

-

Processing temperature: 160 - 280°C

-

Particle size: 3 (± 0.3) mm

-

Packaging: 25 kg/PP or PE bag

-

Storage: Keep in dry conditions

-

Recommended usage rate: 2 - 5%

Please continue to follow and contact EuroPlas to get answers to questions related to plastic materials as well as the earliest updates on knowledge about the global plastic market