According to the United Nations Environment Programme, every day, over 2000 plastic garbage trucks litter the world’s oceans, rivers, and lakes. It is estimated that each year, 19-20 million tonnes of plastic trash are dumped into aquatic ecosystems, not including plastic waste on land. Plastic pollution has become one of the most alerting environmental issues, as the rapidly increasing production of disposable plastic products overwhelms the world’s ability to deal with them.

Thus, enterprises and users tend to look for environmentally friendly plastic alternatives. In recent years, protein-based bioplastics have come to the forefront as an innovative and sustainable solution in dealing with global plastic pollution.

Read more: What are bioplastics made from? Materials to make bioplastics

1. Definition of protein-based bioplastics

Protein-based bioplastics are made from natural proteins such as soy protein, whey protein, and zein. There are so many raw materials suitable for the production of protein plastics, which are of animal origin (casein, fibroin, collagen, keratin, etc.) or of plant origin (gluten, algae, oil, etc.).

2. How are protein-based bioplastics made?

The process of producing protein-based bioplastics

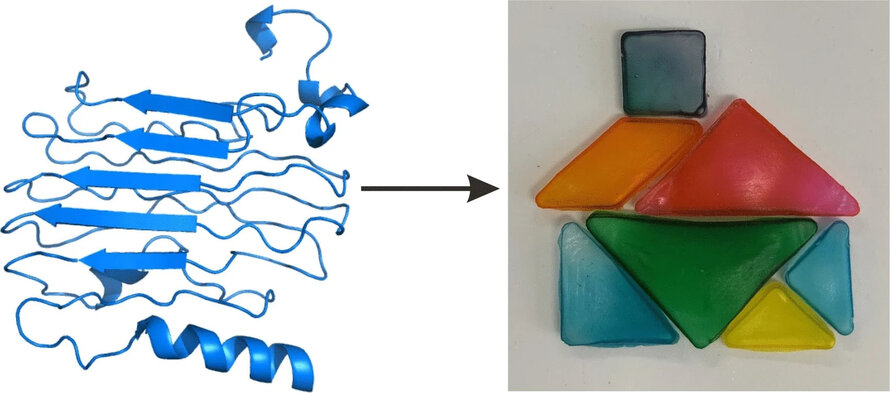

Proteins are chains of amino acids built up or broken down by enzymes. Connecting amino acids with a special enzyme can make biodegradable materials named protein-based bioplastics.

The process of producing protein-based bioplastics involves several main steps:

- Extraction: First, extracting the protein from plant or animal sources by various techniques such as precipitation, filtration, or centrifugation.

- Purification: The protein extracted will be purified to remove impurities or unwanted substances, ensuring it achieves the purest form.

- Mixing and molding: Combining purified protein with other natural ingredients such as starch or cellulose. Then continue molding that mixture into different shapes and forms. In that step, manufacturers can add one or more optional components such as an anti-infective compound, preservatives, plastic additives, etc, to make the final production more perfect.

- Completing: Finally, the protein-based bioplastic is dried and finished to achieve the desired surface properties and meet demands as well as standards on the global market.

Read more: How different types of bioplastics are produced?

3. The future of protein-based bioplastics

The outlook of protein-based bioplastics in the future

Protein-based bioplastics offer great potential as an alternative to conventional plastics in various applications. It is due to their biodegradability and natural origins, which help us deal with plastic pollution. Besides, a key feature of these bioplastics is their antimicrobial activity, which is beneficial to the food industry, pharmaceuticals, medicine, agriculture, etc. Nowadays, more and more ongoing researches focus on enhancing these properties to develop effective and sustainable choices for different industries.

Despite significant benefits, research indicates that protein-based bioplastics are not extensively employed in industrial applications due to several drawbacks. Particularly, when compared to conventional petroleum-based plastics, they have higher costs and inferior performance. Moreover, these bioplastics often struggle with mechanical and barrier properties, and water stability issues because most untreated proteins are hydrophilic. Fortunately, scientists conducted many experiments and continuously endeavored to create a new eco-friendly method that uses rapeseed cake to produce protein-based bioplastics.

Another study shows that there are still some issues that limit wide applications of protein-based packaging such as poor mechanical properties, low moisture resistance, and microbial contamination. To address those drawbacks, several methods to improve the water-resistance properties of protein-based packaging were critically discussed and reviewed. Those approaches include blending, emulsification, conjugation, nanocomposite, enzymatic/chemical crosslinking, polyol-based plasticizer alternatives, and physical treatments. Blending, laminating, or emulsification with hydrophobic materials such as lipids and zein has given promising results.

Additionally, scientists also add extra cross-linking techniques to enhance mechanical properties. Based on the findings of this study, incorporating another cross-linking stage could adjust the properties of protein-based bioplastics.

Achieving the full potential of protein-based bioplastics requires a commitment to continuous innovation and a collaborative approach among scientists, industry experts, and policymakers. By cooperating together, these groups can address existing limitations, explore new opportunities, and drive the advancement of bioplastic technologies. This united effort is essential for overcoming challenges and creating effective solutions for a sustainable future.

4. Conclusion

In conclusion, protein-based bioplastics offer alternative substance solutions for traditional plastics, giving potential options for dealing with plastic waste and environmental protection. However, those materials also have many limitations and challenges that scientists, governments, and enterprises are trying their best to overcome, thus developing perfect bioplastics for various industrial areas. By addressing the drawbacks and embracing advancements, we can look forward to a future where these bioplastics play a significant role in creating cleaner and greener ecosystems.

BiONext 400 bioplastic compound made by EuroPlas

To keep up with the trends of promoting sustainable development, EuroPlas offers a large number of bioplastic compounds created from renewable sources. It is our mission to enhance plastic enterprises' competitiveness and contribute to efforts to decrease fossil raw materials in the global market.

BiONext 400 bioplastics at EuroPlas is a bioplastic compound made from bioplastic and modified starch powder, offering an eco-friendly alternative to traditional plastics. Our compounds show many outstanding mechanical and aesthetic properties including:

- High hardness,

- Significant impact resistance being ideal for injection molding and extrusion,

- Good elongation for applications like blown films,

- A glossy, beautiful surface and easy machining ability,

- Easily breaks down into water, CO2, and biomass within 12 months after disposal, thus causing no harm to the environment.

Thanks to remarkable advantages, EuroPlas’ BiONext 400 bioplastic compound is widely used in various applications, especially single-use cutlery, packaging, and wrapping due to keeping moisture on the surface, resulting in longer food preservation. In addition, we provide types of other compounds for diverse demands such as BiONext 102, BiONext 152, BiONext 500, BiONext 600, and BiONext 700.

Let's build a greener and healthier world with EuroPlas bioplastic compounds! Please contact us for more detailed information.