Understanding the types Of UL94 flame retardant standards is an extremely important category that needs to be widely disseminated

UL9 is an indispensable standard in a world where fire safety is essential. UL94 is applied to most types of plastic materials in production today. This standard provides clear and strict classifications of material fire resistance regulations. UL94 helps protect against everyday fire risks. In addition, manufacturers also have stricter regulations in the process of maintaining product quality control before launching to the market. Understanding the types Of UL94 flame retardant standards is an extremely important category that needs to be widely disseminated. Let's update the UL94 standards and the great benefits they bring right away!

1. What Is UL94 Rating?

These UL94 ratings are important to ensure the safety of plastic components in many different applications

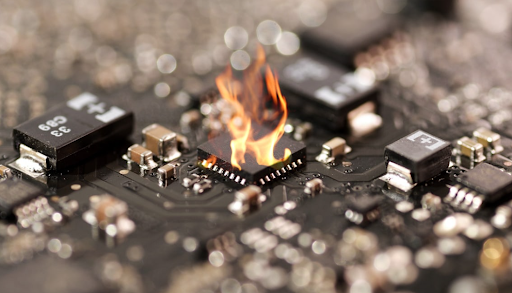

The UL94 rating is known as the standard for the flammability of plastic materials used in appliances and equipment. This is a very popular standard developed by Underwriters Laboratories (UL). First of all, this rating measures the ease with which a material can catch fire. In addition, this UL94 standard helps evaluate the speed at which the material extinguishes after it catches fire. These UL94 ratings are important to ensure the safety of plastic components in many different applications. In particular, UL94 ensures the safety of places that are prone to fire and explosion such as electronic equipment, technical equipment, and household appliances. Therefore, UL94 is very important in ensuring compliance with fire prevention regulations to maintain product quality and ensure consumer safety. UL94 is also a rating that helps facilitate the market acceptance of products made from plastic materials more convincingly.

2. All Types Of UL94 Flame Retardant Standards

The UL94 rating includes several different classifications. Each classification is designed to measure the flammability properties of plastic materials under different conditions. UL94 helps manufacturers and engineers select the right materials for applications that require good flame resistance. Here are the UL94 flame resistance standards.

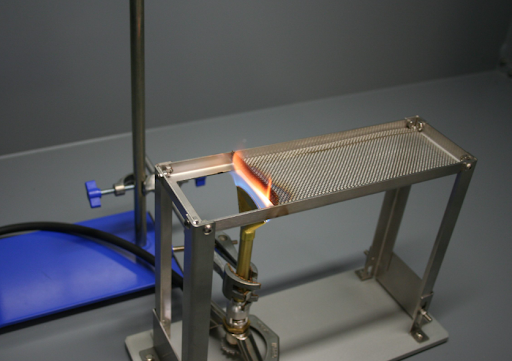

UL94 standard helps evaluate the speed at which the material extinguishes after it catches fire

2.1. Horizontal (HB)

Materials thinner than 3 mm have a standard velocity of less than 76 mm/min. Materials between 3 and 13 mm thick have a standard velocity of less than 40 mm/min. Plastic materials that commonly apply this type of UL94 rating include common plastics used in household items, housings for appliances, toys and electronic devices, etc. Especially ABS plastic used in keyboard cases.

2.2. Vertical (V)

V-0: UL94 rates materials that will stop burning within 10 seconds after the flame is removed and no flame droplets fall. This UL94 rating is typically applied to high-performance electronic equipment materials such as circuit boards, connectors, and enclosures for electrical equipment. For example, Polycarbonate and some types of nylon are common materials in this category.

V-1: Here UL94 rates the material as stopping burning within 30 seconds after the flame is removed and no flame droplets fall. This UL94 rating can be applied to materials used in applications that require moderate flame resistance. Some examples include enclosures for office equipment or automotive interior parts. Specifically, Polypropylene with flame retardant additives can achieve a V-1 rating.

V-2: This is when the material stops burning within 30 seconds after the flame is extinguished. UL94 allows the material to continue dripping as long as it does not ignite. This UL94 rating applies to materials used in applications requiring basic flame resistance, such as the enclosures of some consumer electronics. Typical examples include lower-grade polycarbonates or composites that may achieve a V-2 rating.

UL94 ensures the safety of places that are prone to fire and explosion such as electronic equipment, technical equipment, and household appliances

2.3. Longitudinal (5V)

5VA: The material ceases burning within 60 seconds after five five-second flame applications and does not develop any drops or holes. This UL94 rating applies to plastic materials used in demanding applications such as aerospace, medical devices, and industrial equipment. Some high-performance plastics such as PEEK (polyether ether ketone) may achieve a 5VA rating.

5VB: The material ceases burning within 60 seconds after five five-second flame applications, but may develop holes. This UL94 rating applies to materials used in automotive parts applications, heavy duty electrical enclosures, and some industrial applications. Modified polycarbonate or some flame retardant nylon materials may achieve a 5VB rating.

Understanding the types Of UL94 flame retardant standards is an extremely important category that needs to be widely disseminated

2.4. Longitudinal for thin materials

VTM-0: For thin materials, the material ceases to burn within 10 seconds after the flame is extinguished, with no flame droplets. This UL94 rating applies to thin films and shields. Some common items include insulating films for capacitors, flexible printed circuit boards, or thin protective covers. Some types of polyester films typically meet this UL94 standard.

VTM-1: For thin materials, the material ceases to burn within 30 seconds after the flame is extinguished, with no flame droplets. This UL94 rating applies to thin materials used in applications requiring moderate flame resistance such as thin insulation, tapes, and some thin-walled piping. Some polyethylene films may achieve a VTM-1 rating.

VTM-2: For thin materials, the material ceases to burn within 30 seconds after the flame is removed, but flame droplets are permitted. This UL94 rating applies to thin materials used in applications requiring moderate flame resistance. Certain thin acrylic or PVC films may achieve a VTM-2 rating.

UL94 brings enormous benefits to both manufacturers and consumers

2.5. Horizontally for foam materials

HF-1: The material ceases to burn within 2 seconds after the flame is removed, with no flame droplets. UL94 is rated for foams used in critical applications such as medical devices, automotive interior components, and advanced packaging materials. Examples include some polyurethane foams.

HF-2: The material ceases to burn within 2 seconds after the flame is removed, but flame droplets are allowed. UL94 is rated for foam materials used in applications requiring moderate flame resistance such as furniture padding, mattresses, and automobile seats. Some flexible polyurethane foams can achieve an HF-2 rating.

HBF: The material burns at a slow rate without flame droplets. UL94 is rated for foam materials used in applications requiring minimal flame resistance such as basic packaging foam, some upholstery foams, and craft foams.

3. Why is UL94 Important?

UL94 helps ensure that plastic materials used in consumer products do not pose a significant fire or explosion hazard

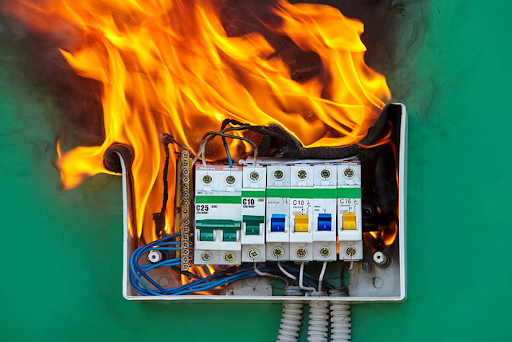

Safety Assurance: For human safety, UL94 helps ensure that plastic materials used in consumer products do not pose a significant fire or explosion hazard. The ability to classify materials based on the flammability level of the UL94 standard helps protect consumers from fire risks and property damage. In industry, using materials that meet UL94 standards can effectively prevent fires. UL94 helps protect workers, equipment, and facilities from unwanted accidents.

Material selection: UL94 ratings are trusted and used by many engineers and designers today. UL94 can help choose the right materials for each different project. Applying UL94 will help clarify the fire resistance of materials, thereby making decisions about the right materials for specific applications. UL94 thus helps ensure both product performance, safety and cost optimization.

Ensure compliance with fire regulations: Currently, in many different industries, UL94 rating is a trusted and widely recognized standard. According to UL94, products that do not meet UL94 standards may not be allowed to circulate on the market. This is one of the factors that requires manufacturers to strictly comply with fire regulations. From there, manufacturers will always maintain quality control and ensure that their products always meet safety requirements. In addition, products that meet these UL94 standards are often more marketable because they are safer.

Meet international standards: UL94 is highly appreciated and recognized worldwide. UL94 facilitates global trade by ensuring that products meet safety standards in different countries. This allows manufacturers to expand their markets without having to undergo extensive testing.

Liability: UL94 can reduce liability risks by using materials that comply with the established standards. In the event of an accident, UL94 certification can help demonstrate due diligence and mitigate liability.

4. Conclusion

In conclusion, the UL94 standard is considered an extremely important standard to ensure the fire resistance of plastic materials. Understanding the specific requirements of UL94 will help the production process become more and more efficient. In addition, human health and life are also protected thanks to the UL94 standards. It can be said that UL94 brings enormous benefits to both manufacturers and consumers. Therefore, UL94 needs to be widely disseminated and more strictly regulated worldwide.

5. About EuroPlas

EuroPlas is proud to be one of the most trusted and reputable material suppliers worldwide. You can easily find and buy bio-fillers, color masterbatches, plastic additives, engineering plastic compounds and bio-plastic compounds, etc. with just one click. In particular, EuroPlas provides high-quality flame retardant plastic products such as PBT GF-FR, PC-FR, HIPS, ABS-FR, PP-FR and some flame retardant additives. Besides, visit EuroPlas blog today for more useful information about materials. We are an optimal material solution provider with a wide range of high-quality plastic lines. Our solutions meet the diverse needs of industries around the world, not only in terms of high standards and reliability but also in terms of environmental obligations.