Commodity plastics in our lives

Let's try a practical demonstration of the presence of plastic in our lives. Looking at desks, bedrooms, living rooms, bathrooms, plastic is almost everywhere. In particular, plastic products have been recognized by many manufacturers as an indispensable factor for the development of their businesses. The importance of choosing the right material not only gives users a satisfactory product but also makes a great contribution to improving the cost efficiency of the business. Every year, the goods manufacturing industry produces a large number of commodity plastics in many fields such as medicine, health care, beauty, food and beverage, and entertainment. Stay here to learn about the outstanding properties and diverse transformations of this compound. See more right below!

1. What is commodity plastic?

Commodity plastics beads

Commodity plastic has been around for a long time and is still present in our lives today. Typical examples of commodity plastics include household products, packaging, food trays and containers, bottles, bags, packaging films, or product protective packaging. Commodity plastics are produced in large quantities every year based on high consumer demand. Thanks to its high and diverse applications, commodity plastics are present almost everywhere in human life. The big advantage of this compound is cost savings, so it can bring businesses very high profits every year.

2. List of commodity plastics and appliactions

Commodity plastic is a type of plastic with low price but very high applicability. The materials are divided into different groups based on the purpose for how they are used. Some types can be mentioned as follows:

Bags made of Polyethylene

Polyethylene has the chemical formula C2H4 and the generalized chemical formula is (C2H4)n. This type of substance may also be called polythene and is abbreviated as PE. The density of polyethylene can be from 0.88 grams per cubic centimeter to 0.96 grams per cubic centimeter. The melting temperature of this type is ranging from 115 degrees Celsius to 135 degrees Celsius, relatively low. From this, it can be said that polyethylene has poor heat resistance. The most common types of PE are low density (LDPE), medium density (MDPE) and high density (HDPE).

PE is becoming the leading choice to replace high-cost materials on the market, thereby saving a large amount of costs for investors. Because its heat resistance is not too impressive, it is considered flexible plastic. PE is most commonly used in applications such as agricultural packaging, mattress, bags, bottles, bubble wrap, food packaging, industrial lining. Most products made from PE are disposable so they are in very high demand in the market.

Food containers made of Polypropylene

Polypropylene has the chemical formula C3H6 and the generalized chemical formula is (C3H6)n. This type is also known by other names as polypropene and is abbreviated as PP. The density of amorphous polypropylene is known to be 0.855 grams per cubic centimeter while the density of the crystalline variant is closer to 0.95 grams per cubic centimeter. This is a non-polar polymer. In terms of properties, the melting temperature of this plastic usually ranges from 130 degrees Celsius to 171 degrees Celsius. This makes polypropylene malleable when heated to a certain temperature.

PP is also a form of flexible plastic but is harder and more heat resistant than PE. Polypropylene plastic beads are transparent white, colorless, odorless, tasteless, and non-toxic, so they are easy to mix to create eye-catching colors. PP stands out with properties such as chemical resistance and is safe for health, so it is used to produce potable water bottles and 20-liter water bottles. Besides, features such as good elasticity, anti-deformation, and electrical insulation which can be used for electronics and technology. PP is transparent so it is also used in food container designs.

Read more: PP Plastic: Everything you need to know

Polyvinyl Chloride applied in plumbing

Polyvinyl Chloride has the chemical formula CH2=CHCl or C2H3Cl. The abbreviation is PVC. The melting point of PVC is known to range from 100 degrees Celsius to 260 degrees Celsius. Polyvinyl chloride is divided into two basic forms: rigid PVC (or RPVC) and flexible PVC. Rigid PVC is mainly used in the construction industry. Flexible PVC is known to have applications in electrical engineering.

PVC also has a reasonable cost, so it is also one of the notable options for investors. The volume of products which are manufactured from this type can be up to several tens of millions of tons per year. In addition to its low price, PVC is also popular thanks to its ability to resist environmental degradation and chemical resistance. PVC can be used in profiled applications such as doors and windows, pipes, plumbing, flooring as an alternative to rubber. In addition, it is also used in electric cables thanks to its effective electrical insulation properties.

Read more: PP Vs PE Plastic: Which One To Choose?

Food trays made of Polystyrene

Polystyrene has a generalized chemical formula is (C8H8)n. The abbreviation is PS. The melting point of PS is known to Approximately 240 degrees Celsius. In terms of properties, this is a hard plastic and is the most widely used plastic. This compound can be melted and hardens as it cools. Although insoluble in water, this type can be dissolved by many aromatic hydrocarbon solvents and chlorinated solvents.

PS is often a great choice and plays a key role in the packaging industry. PS is widely used to produce packaging items, insulated packaging and single-use food containers. This is also a material used for products in direct contact with water because it has quite good water resistance.

Read more: Different Plastic Types: What You Need to Know

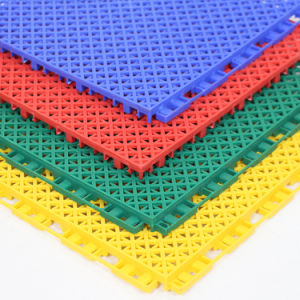

Durable PET plastic mats

Polyethylene Terephthalate has the chemical formula (C10H8O4)n. The abbreviation is PET. The melting point of Polyethylene Terephthalate is known to be between 245 degrees Celsius and 265 degrees Celsius. It is a transparent and semi-crystalline natural plastic. It is also the most widely recycled because of its ability to resist microorganisms. Among its properties, hardness and stiffness, good durability, ductility are the most prominent

PET is quite safe for health thanks to its antibacterial properties, so it is used in water bottles, food bags, food containers, and packaging films. To maximize its durability, people have used it to produce products such as plastic mats and microwave boxes.

Read more: Differences Of Plastic Resin And Filler Masterbatch In Overall

Common plastics are generally quite diverse in properties and applications. Plastic products bring price perfection to consumers and great economic benefits to investors. See more outstanding plastics here!

3. About EuroPlas

EuroPlas is honored to be one of the world's leading manufacturers with more than 16 years of experience in the field of filler masterbatch production. We are proud to bring investors PE filler masterbatch and PP filler masterbatch with the best quality. Contact EuroPlas immediately for more information and solutions for choosing the most optimal plastic material for a variety of products!