Fiberglass polycarbonate compound, which combines fiberglass with polycarbonate, is a versatile material that is lightweight yet strong. This article aims to delve into the advantages and typical applications of fiberglass polycarbonate and provide insights into its properties and manufacturing process.

Table of Contents

1. What is Fiberglass Polycarbonate?

a. Definition

b. Composition

c. Manufacturing Process

2. Exceptional Benefits of Fiberglass Polycarbonate

a. Strength and Durability

b. Weather Resistance

c. Light Transmission

3. Different Types of Fiberglass Polycarbonate

3.1. PC-GF 10

3.2. PC-GF 20

3.3. PC-GF 30

4. Application of Fiberglass Polycarbonate

a. Automotive Industry

b. Electronics and Electrical Components

c. Consumer Goods

d. Aerospace and Defense

e. Industrial Machinery

g. Medical Devices

h. Others

5. Conclusion

6. Introduction of EuroPlas Glass Fiber Polycarbonate

7. FAQs

1. What is Fiberglass Polycarbonate?

A composite material called fiberglass polycarbonate combines the durability of fiberglass with the transparency and impact resistance of polycarbonate. It finds extensive usage in scenarios requiring robustness, excellent weather resistance, and light transmission.

a. Definition

Distinguished by versatility and durability, Fiberglass polycarbonate (PC-FG) presents an amalgamation of fiberglass's strength and polycarbonate's impact resistance and transparency. This makes it a preferred choice for applications demanding exceptional strength, superior weather resistance, and ample light transmission.

b. Composition

Fiberglass and polycarbonate are the two main components of fiberglass polycarbonate. glass-reinforced plastic (GRP) is a composite material incorporating fine glass fibers embedded within a polymer matrix. Polycarbonate, a transparent thermoplastic, boasts outstanding impact resistance and optical properties.

c. Manufacturing Process

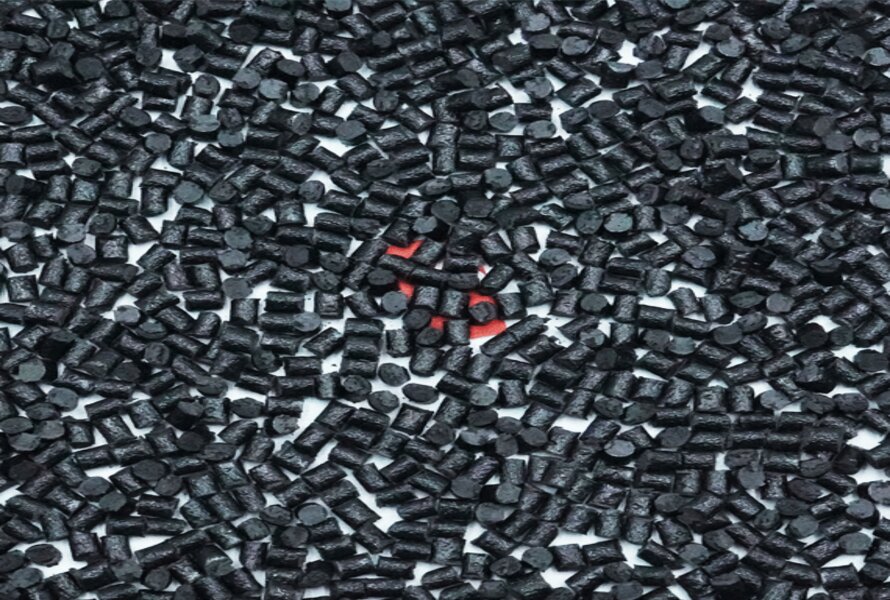

The manufacturing process of PC-GF involves:

- Raw material preparation, weighing and mixing of polycarbonate resin and glass fibers

- Compounding through melting

- Blending, pelletization, molding using injection or other processes

- Cooling, finishing, quality control, and packaging for distribution

Variations in the process can occur based on manufacturer and application requirements, with advanced technologies employed for specific performance and efficiency enhancements.

Fiberglass polycarbonate compound

2. Exceptional Benefits of Fiberglass Polycarbonate

Fiberglass polycarbonate offers many advantages, contributing to its popularity across diverse industries. Let's explore its outstanding features:

a. Strength and Durability

PC-GF has exceptional strength and impact resistance because of the fiberglass reinforcement, which makes them perfect for applications where structural integrity is important. They can withstand heavy loads, hail, and other harsh weather conditions, ensuring long-term durability.

b. Weather Resistance

Fiberglass polycarbonate demonstrates high resistance to UV radiation, preventing yellowing and maintaining clarity over time. It also exhibits excellent tolerance to extreme temperatures, making it suitable for hot and cold climates.

c. Light Transmission

One key advantage of fiberglass polycarbonate is its exceptional light transmission capabilities. Allowing natural light to pass through reduces the need for artificial lighting, resulting in energy savings and creating a pleasant indoor environment.

Exceptional Benefits of Fiberglass Polycarbonate compound

3. Different Types of Fiberglass Polycarbonate

There are various types of PC-GF available in the market, each with a different ratio of polycarbonate and glass fiber content. The most common types include:

3.1. PC-GF 10

- Description: PC-GF 10 is a PC-GF grade with 10% glass fiber content.

- Properties: This type offers good mechanical strength and dimensional stability, making it suitable for applications where moderate reinforcement is required.

- Applications: PC-GF 10 is commonly used in consumer electronics, such as laptop casings and smartphone components.

3.2. PC-GF 20

- Description: PC-GF 20 contains 20% glass fiber content, providing higher reinforcement than PC-GF 10.

- Properties: PC-GF 20 offers improved mechanical strength, stiffness, and impact resistance compared to PC-GF 10.

- Applications: It finds applications in automotive parts, electrical connectors, and housing for power tools.

3.3. PC-GF 30

- Description: PC-GF 30 contains 30% glass fiber content, offering further reinforcement and improved mechanical properties.

- Properties: This type exhibits excellent strength, rigidity, and impact resistance, making it suitable for demanding applications.

- Applications: PC-GF 30 is often used in automotive components, industrial machinery parts, and structural components.

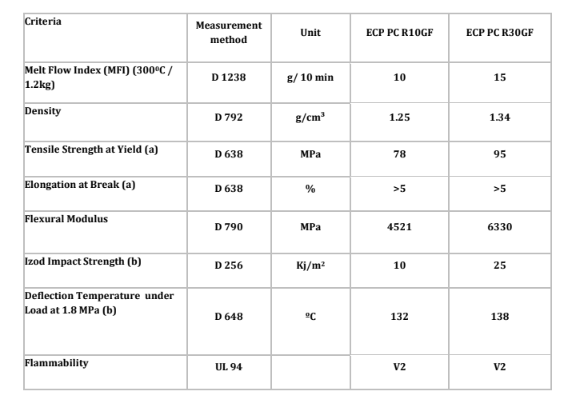

Specifications of Compound PC GF

4. Application of Fiberglass Polycarbonate

a. Automotive Industry

The automotive industry extensively utilizes PC-GF compounds due to its exceptional mechanical properties and lightweight nature. It finds applications in:

- Exterior Parts: PC-GF compound is used for manufacturing exterior parts such as bumpers, grilles, mirror housings, and body panels, providing impact resistance and dimensional stability.

- Interior Components: It is utilized for interior components like instrument panels, door handles, and trim parts, offering a balance between aesthetics and durability.

Automotive Industry

b. Electronics and Electrical Components

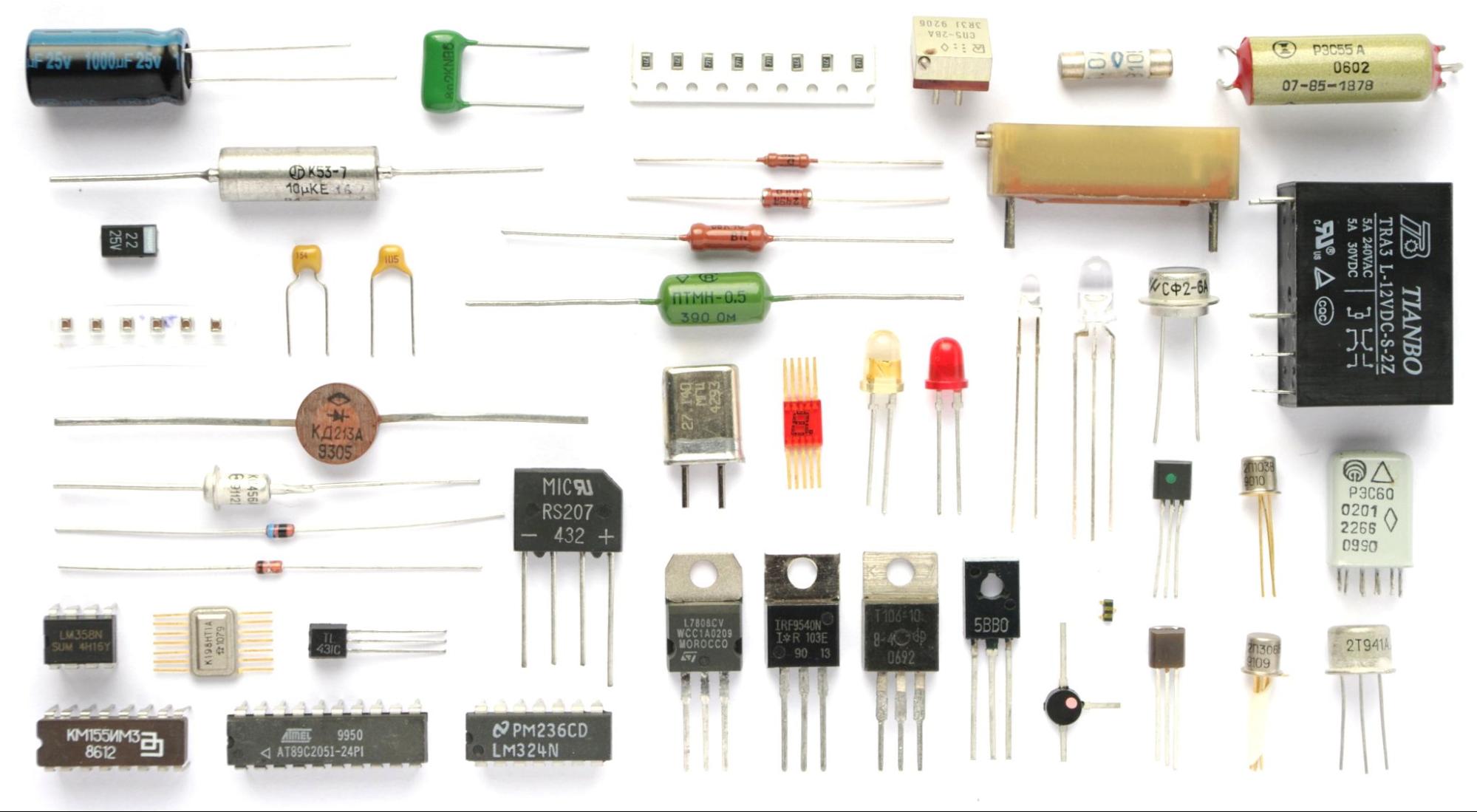

PC-GF compound's combination of electrical insulation properties and mechanical strength makes it suitable for various electronic and electrical applications, including:

- Connectors and Housings: PC-GF compound is used for manufacturing connectors, sockets, and housing components for electronic devices, ensuring durability and electrical safety.

- Circuit Boards: It finds applications in the production of circuit boards, where its heat resistance and dimensional stability are crucial.

Electrical Components

c. Consumer Goods

PC-GF compound is employed in the consumer goods industry, where both strength and aesthetics are essential. Some applications include:

- Appliances: It is used for manufacturing components of appliances like blenders, coffee makers, and vacuum cleaners, providing impact resistance and heat resistance.

- Sporting Goods: PC-GF engineering plastic compound finds use in the production of sporting goods such as helmets, protective gear, and equipment, offering impact resistance and strength.

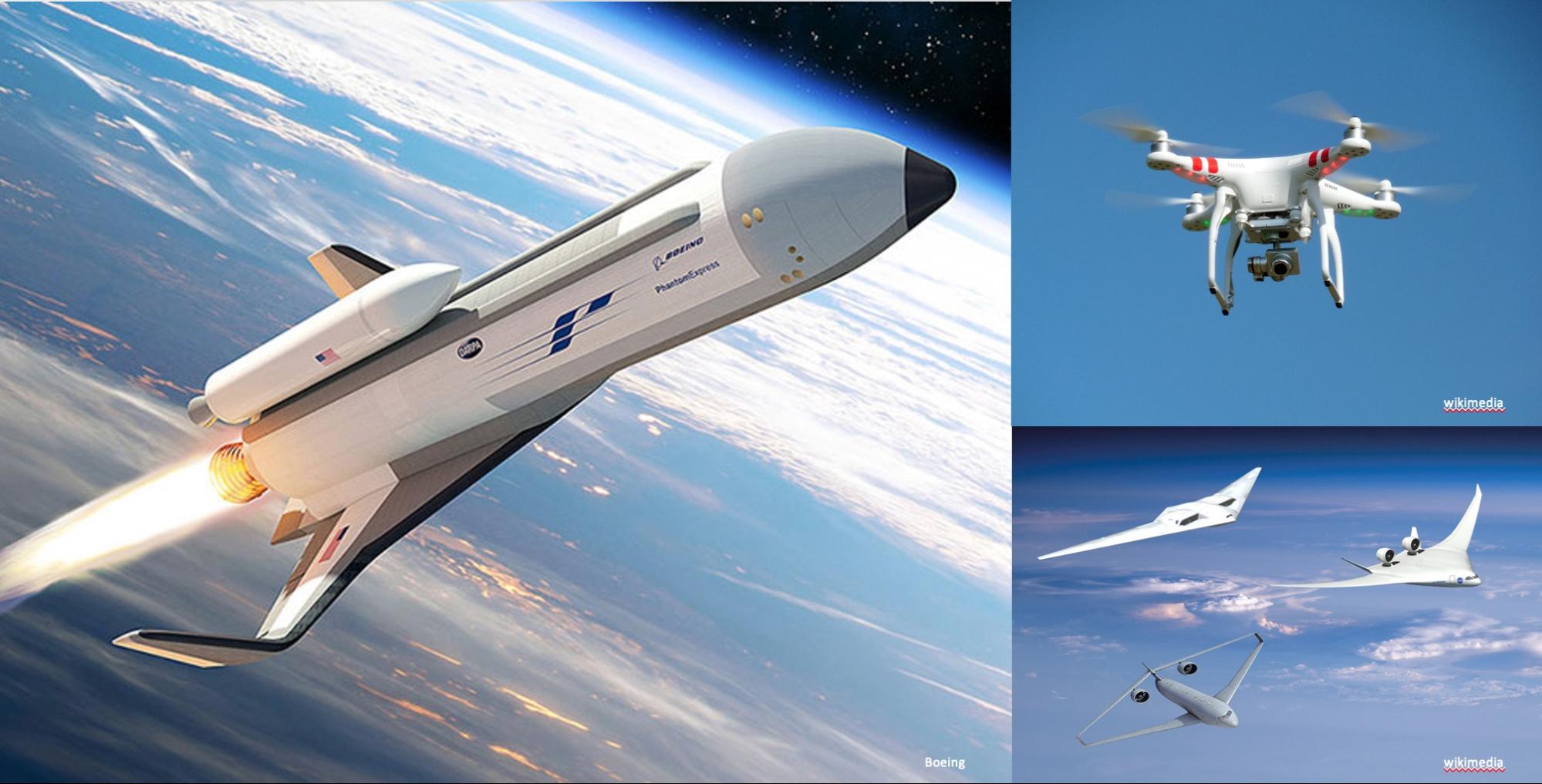

d. Aerospace and Defense

PC-GF compound is utilized in the aerospace and defense sectors, where high performance and reliability are critical. It finds applications in:

- Aircraft Interiors: PC-GF compound is used for manufacturing interior components of aircraft, including panels, trays, and seating, offering lightweight and fire-resistant solutions.

- Defense Equipment: It is employed in the production of defense equipment such as helmets, protective shields, and vehicle components, providing impact resistance and durability.

Aerospace

e. Industrial Machinery

PC-GF compound plays a significant role in the manufacturing of industrial machinery, where durability and reliability are essential. It finds applications in:

- Machine Components: It is used for manufacturing machine components like gears, casings, and structural parts, providing strength and resistance to wear.

- Conveyor Systems: PC-GF compound is employed in the production of conveyor systems, offering high load-bearing capacity and dimensional stability.

Industrial Machinery

f. Medical Devices

PC-GF compound is utilized in the medical industry for various applications that require a combination of strength, sterilizability, and chemical resistance. Some applications include:

- Surgical Instruments: It is used for manufacturing surgical instruments like forceps, clamps, and handles, providing strength and resistance to sterilization processes.

- Medical Equipment Housings: PC-GF compound finds use in the production of medical equipment housings, ensuring durability and resistance to chemicals and disinfectants.

g. Others

Apart from the aforementioned industries, PC-GF compound also finds applications in areas like construction, telecommunications, and renewable energy, where its unique properties cater to specific requirements.

5. Conclusion

The strength of fiberglass is combined with the transparency and impact resistance of polycarbonate to create an amazing material. It is the perfect option for many applications because of its remarkable qualities, which include strength, weather resistance, light transmission, thermal insulation, and fire resistance.

6. Introduction of EuroPlas Glass Fiber Polycarbonate

EuroPlas is a renowned manufacturer and supplier of top-quality glass fiber polycarbonate . With a commitment to excellence and innovation, EuroPlas has established itself as a trusted name in the industry. Our products undergo stringent quality control measures, ensuring exceptional performance and durability. The combination of fiberglass reinforcement and polycarbonate resin results in a product that withstands the test of time and various environmental conditions.

EuroPlas offers a diverse range of glass fiber polycarbonate to cater to different applications.

EuroPlas understands the importance of natural light in design and construction. Our glass fiber polycarbonate allows maximum light transmission, creating bright and inviting spaces. Additionally, it provides effective UV protection, shielding interiors from harmful radiation.

With comprehensive technical support, EuroPlas assists customers with product selection. We focus on sustainability, manufacturing using eco-friendly processes and materials. Trusted by professionals, EuroPlas pc-gf has been successfully implemented in various projects.

EuroPlas glass fiber polycarbonate offers a winning combination of strength, durability, and aesthetic appeal. Choose EuroPlas for high-quality glass fiber polycarbonate engineering plastic compound solutions.

EuroPlas Glass Fiber Polycarbonate (PC-GF) compound

7. FAQs

Is fiberglass polycarbonate suitable for outdoor use?

- Yes, fiberglass polycarbonate is highly weather-resistant and can withstand harsh outdoor conditions, including UV radiation, temperature fluctuations, and impact.

What does PC-GF stand for?

- PC-GF stands for Polycarbonate Glass Fiber.

What are the benefits of using PC-GF?

- The benefits of using PC-GF include its high strength and stiffness, excellent impact resistance, dimensional stability, and resistance to heat and chemicals.

Is PC-GF suitable for outdoor applications?

- Yes, PC-GF is suitable for outdoor applications due to its excellent weatherability and UV resistance.

Can PC-GF be recycled?

- Yes, PC-GF is recyclable. It can be processed and reused to create new products, reducing waste and promoting sustainability.

Is PC-GF expensive compared to other materials?

- The cost of PC-GF can vary depending on factors such as the application, quantity, and supplier. While it may be slightly more expensive than some other materials, its superior mechanical properties and durability often justify the investment.