Most of us are familiar with Nylon as we see it in many daily applications. Since the properties of Nylon are outstanding, it's an ideal choice for manufacturers to use for their end products.

Our article will give you a close look at the material and their features in detail. Plus, we will introduce our high-class EuroPlas PA (Nylon) engineering plastic compound for your reference. Hesitate no more but scroll down right now!

1. What are nylons?

Nylon refers to the synthetic polymers family, which is composed of polyamides. These repeating polymer patterns are formed by linking amide links. Nylon chemical structure is (C6H11NO)n.

Is Nylon a thermoplastic? Yes, plastic Nylon is silk-like thermoplastic made from petroleum, which usually goes through the melting process into various shapes, firms, and fibers.

Is Nylon a polymer? Yes, and this nylon polymer can be used as a base to combine with different additives to obtain a broad range of textures and properties suitable for specific product requirements. There are five common types of this material, including nylon 6,6, nylon 6, nylon 510, nylon 4,6, and nylon 1,6. They all possess strength, elasticity, lustrousness, resiliency, and damage resistance at different levels.

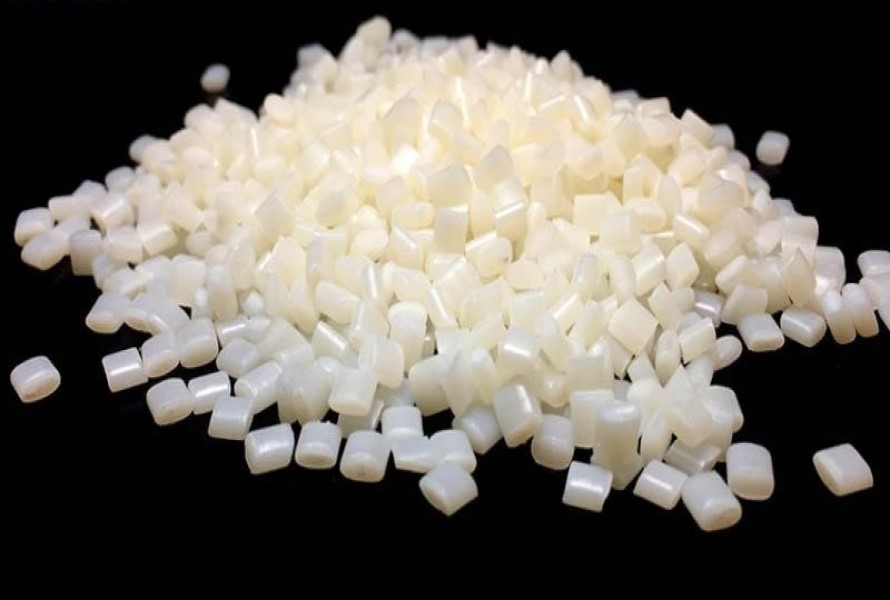

Nylon

Read more: Nylon 6: Definition, properties and common uses

2. Properties of Nylon

2.1 Nylon density g/cm3

The density of Nylon is slightly different between types, yet the average number is around 1.14 g/cm3.

2.2 Nylon chemical compatibility

In general, Nylon is gasoline, fuels, oils, mineral spirits, and some alcohol resistant. The material is not compatible with ozone and most acids.

2.3 Nylon heat resistance

The melting point of Nylon is the highest among thermoplastics, meaning it’s heat resistant. The Nylon melt temperature is 220°C or 428°F.

Nylon flammability: It will not ignite until it reaches the temperature of 420 to 530°C or 788 to 986°F.

2.4 Nylon uv resistance

This thermoplastic is sensitive to UV rays, meaning it's susceptible to degradation under sunlight. However, its UV resistance varies depending on the nylon variation. For example, Nylon 6 or Nylon 12 tolerates UV radiation better than Nylon 6,6.

2.5 Modulus of elasticity of Nylon

The modulus of elasticity of Nylon is 0.4 x 106 psi or 2.7 GPa.

2.6 Glass transition temperature of Nylon

This value depends on the types of Nylon, the molecular weight distribution and additives influences. For example, the glass transition temperature of dry nylon 6 is 47 °C or 117 °F, while this figure in dry nylon 6,6 is 70 °C or 158 °F.

2.7 Nylon yield strength

The material has a yield strength of 45 - 90 MPa.

3. Nylon sustainability

Nylon is strong, durable, and can be molded into shape. Yet, none of its forms is biodegradable, meaning its final products will stay on land for hundreds of years.

Can Nylon be recycled? The good news is yes. Though recycled products are still non-biodegradable, the nylon recycling process is encouraged. Instead of producing new Nylon, we can reuse used Nylon and turn it into new material. Thus, less oil will be extracted from the Earth.

4. Is nylon food safe?

Yes, nylon plastic is a common food-safe thermoplastic since its chemical features don't come into food while cooking. Nylon properties allow it to be an alternative to rubber, wood, brass, and steel.

5. Uses of Nylon

Nylon appliance

Nylon is widely available in many final products. Some of its uses include:

- Clothing production: from shirts, foundation garments, swimwear, and raincoats to military supplies such as ropes, ponchos, and tents.

- Fishing nets: Plastic is an ideal option for fishnets since it's strong, lightweight, and wear and tear tolerant. Especially, it has tensile strength, allowing the net to hold more weight without breaking.

- Machine part: Manufacturers usually mold the plastic into different sheets and forms for pipes, tubes, bolts, and screws. Besides, it's easy to be melted into filaments, making it useful for packaging, sheet stock, films, or 3d printing.

- Machine parts: The lightweight, durable, heat and chemical-resistant properties of Nylon are suitable for many machine parts such as bolts, nuts, and screws.

Since Nylon thermal conductivity is good, it's also a common material for many electronic items, including electrical cords and circuit boards. Besides, manufacturers apply plastic in the appliance bearings since it has a low coefficient of friction and excellent abrasion resistance.

6. How much does Nylon cost?

Nylon is considered a low-cost material, which is around 3 dollars per kg. Note that the price varies depending on time, nylon forms, and where you buy it from.

7. Introduction of EuroPlas PA (Nylon) engineering plastic compound

Understanding the market demand for an all-in-one stable and high-quality material for protection, EuroPlas has successfully developed a PA (Nylon) engineering plastic compound for our customers. The most highlighted items of our products include PA6, PA66 blend compound, and PA66, PA6 Glass fiber compound.

Polyamide-6 (PA6) and Polyamide-66 (PA66) are among the top choices for manufacturing, thanks to their outstanding properties. The former is cheaper, easier to process, and distorts less, while the latter is stiffer and has higher temperature resistance and better abrasion resistance. EuroPlas has added other additives to the PA6 and PA66 resin to increase their performance.

7.1. PA6, PA66 Blend compound

Blend PA compound

PA6, PA66 Blend compound combines PA6/PA66 resin, elastomer, and impact strength modifiers, giving it resiliency and strong mechanical properties. This material from EuroPlas will help you produce mechanically strong and highly precise final products. Its application includes roller bearings, carburetors, control valves, exhaust gas, and other gear-related components.

7.2. PA66, PA6 Glass fiber compound

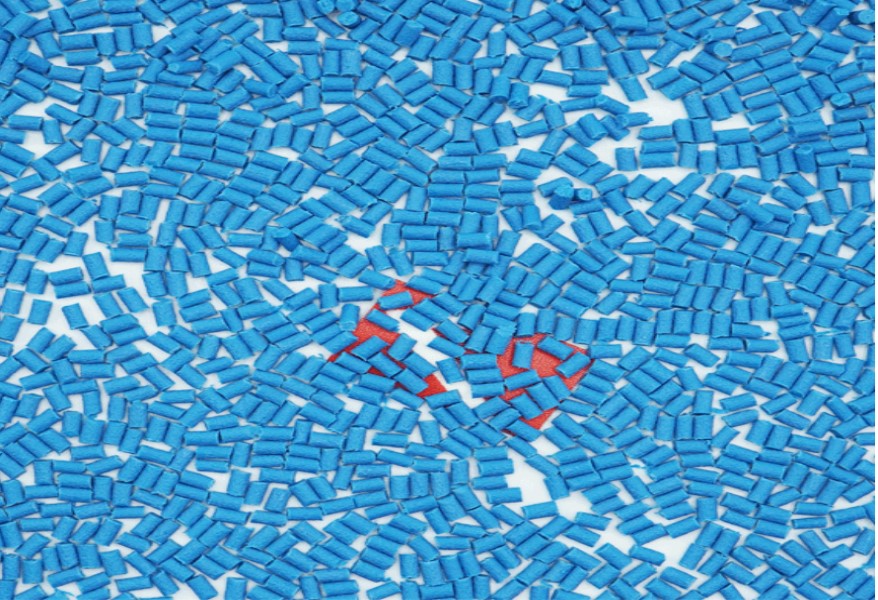

Pa6 Pa66 glass fiber compound

PA resin is mixed with glass fiber reinforced, providing the PA66 and PA6 Glass fiber compound with toughness, mechanical strength, high heat deflection temperature, chemical resistance, and wear resistance. With 30-50% of glass fiber, EuroPlas PA66, PA6 Glass fiber compound is ideal for producing drive belts, bearings, gears, carburetor components, household electrical components, and computer details.

Conclusion

We can see the applications of Nylon almost everywhere, from clothing to manufacturing, since it's strong, durable, elastic, damage resistant, and relatively cheap. The plastic is stable and easy to be molded. If you're looking for some good deals on PA (nylon) engineering plastic compound, EuroPlas is always ready with good offers.