In the world of industrial materials production, a small but extremely important ingredient is TiO2, also known as titanium dioxide. When it comes to white pigments, TiO2 is always the first mentioned due to its significant influence on the quality and performance of the final product. The presence of TiO2 in white pigments has opened up countless application possibilities across diverse industries, from paints and plastics to paper, cosmetics, and food. So, what effects does TiO2 truly bring to white masterbatch?

In this article, EuroPlas will explore with readers the amazing effects of TiO2 in white masterbatch and discover how a small compound can create such a big impact, from improving product quality to ensuring safety for users and the environment.

1. Overview of TiO2

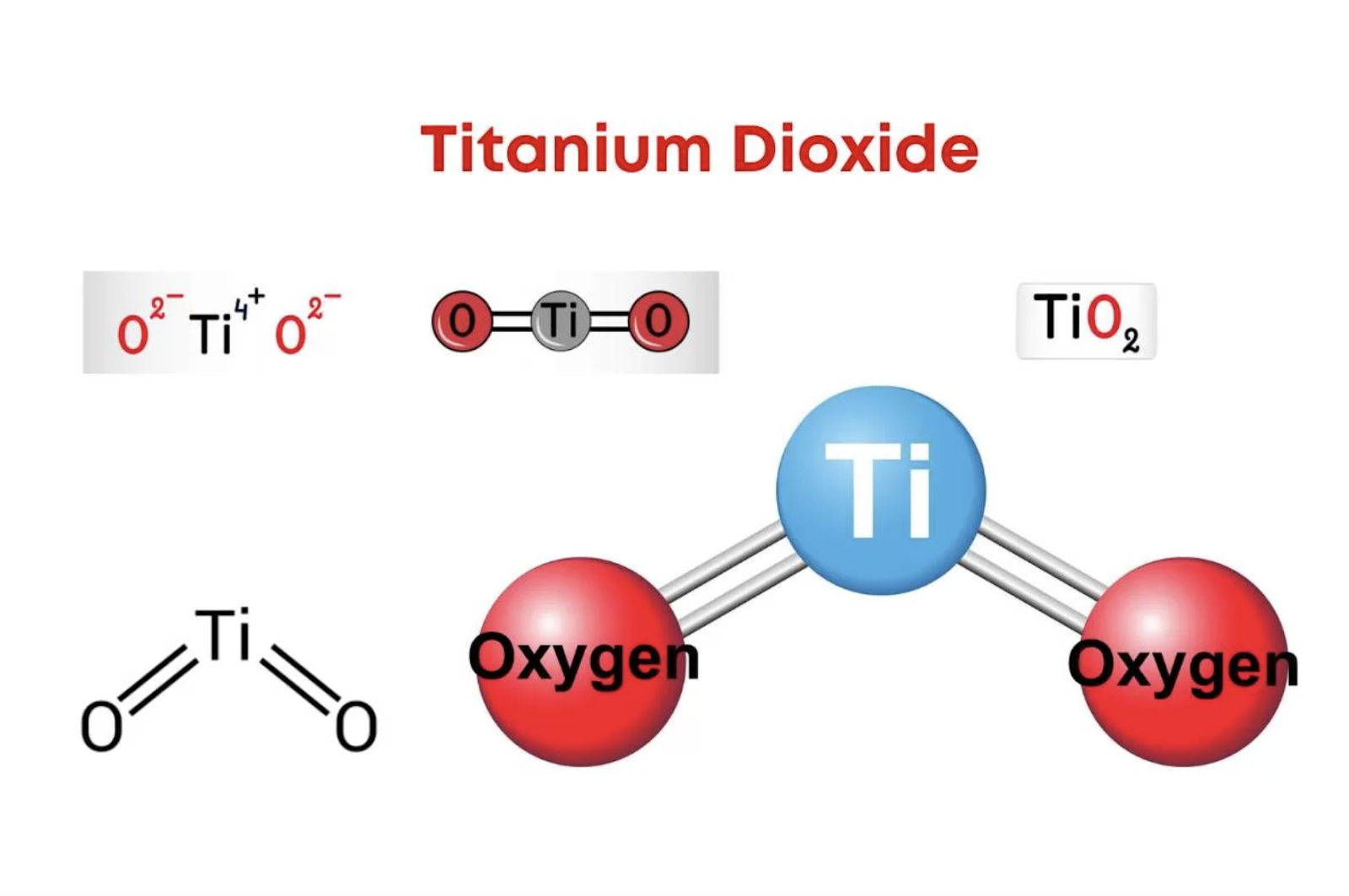

TiO2, also known as Titanium Dioxide, is an inorganic compound with the chemical formula TiO2. It is an odorless, tasteless white powder that is widely used in many different industries, especially in the production of white masterbatch, paints, printing inks, plastics, and other consumer products.

TiO2 is not just a simple white masterbatch. It is a versatile compound with many superior properties, from the ability to create pure whiteness, superior color fastness, to the ability to protect against UV rays and improve the mechanical properties of materials. TiO2 has gradually become an indispensable ingredient in many industrial applications and daily life.

See more:

What is titanium dioxide? Titanium dioxide used in plastic

What is color masterbatch and how was masterbatch produced?

1.1. Structure and chemical properties of TiO2

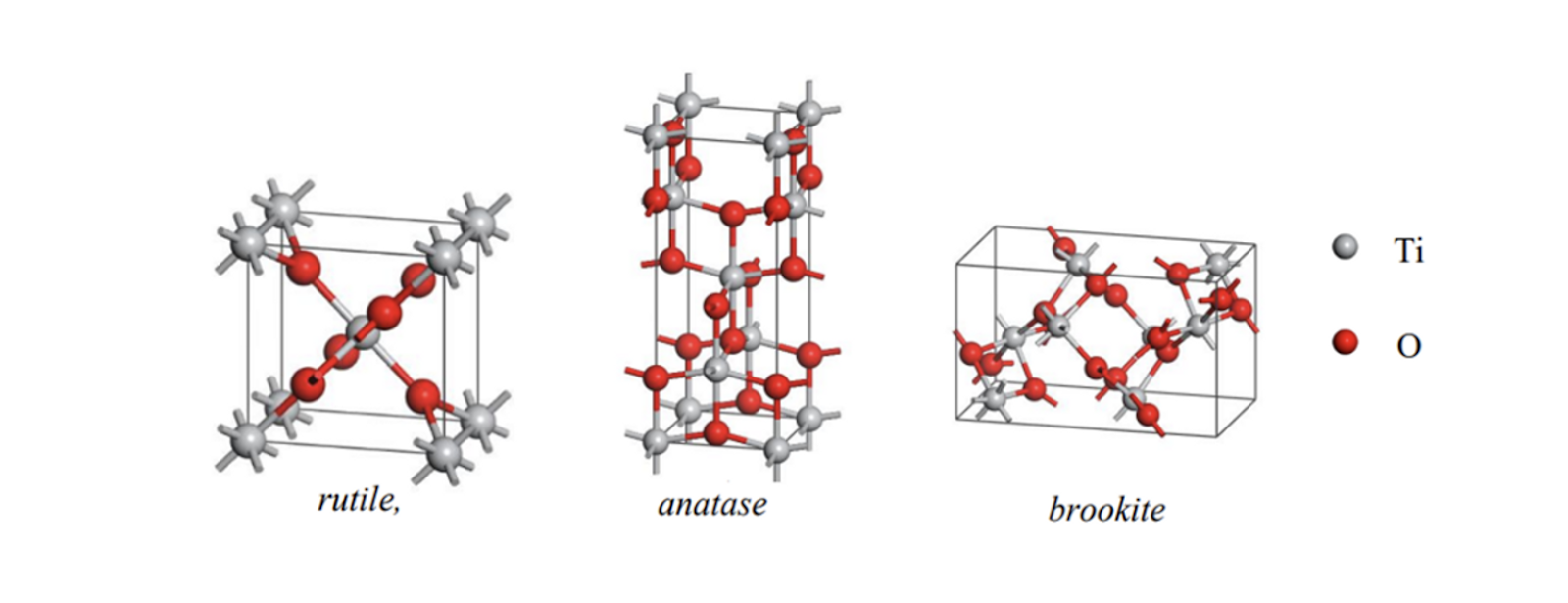

TiO2 has a polymorphic crystal structure, which means it exists in many different structural forms. Rutile is the most common form of TiO2 and is widely used in industry due to its high stability and large refractive index. The other two common forms are Anatase and Brookite.

Chemically, TiO2 is a fairly inert compound, insoluble in water and most organic solvents, and only soluble in hydrogen or hydrofluoric acid. This property helps TiO2 to be highly durable in many different environmental conditions.

1.2. TiO2 production process

TiO2 is produced through two main methods:

- Sulfate method: Ilmenite ore (FeTiO3) is treated with sulfuric acid to produce titanyl sulfate, which is then hydrolyzed and calcined to produce TiO2.

- Chloride method: Rutile or ilmenite ore is treated with chlorine and carbon at high temperature to produce TiCl4, which is then oxidized at high temperature to produce TiO2.

Each method has its own advantages and disadvantages, and the choice of production method depends on many factors such as raw material source, product quality requirements and environmental regulations.

1.3. Outstanding properties of TiO2

TiO2 possesses several unique properties, making it an important ingredient in many applications:

| UV protection |

TiO2 effectively absorbs UV rays, protecting materials from sunlight-induced decomposition and discoloration. This property is especially important for outdoor applications or products requiring high color fastness.

|

| High durability and stability |

TiO2 boasts a stable chemical structure, resisting decomposition from factors like light, temperature, or humidity. This ensures the product's color and other properties remain intact over time.

|

| Photocatalytic activity |

Under UV light, TiO2 generates free radicals that decompose organic substances. This property is utilized in self-cleaning and environmental treatment products.

|

| Outstanding whiteness |

With a high refractive index of 2.7 for rutile, TiO2 reflects nearly all visible light, producing a bright, pure, and uniform white effect. This makes it the premier choice for creating white products or enhancing the brightness of other colors.

|

| Environmentally friendly |

TiO2 is considered safe for various applications, including products in direct contact with humans, such as cosmetics and food.

|

1.4. Applications of TiO2

TiO2 has a wide range of applications across various industries, including:

- Cosmetics: Sunscreen, makeup powder, etc.

- Food: Coloring in some foods.

- Paper and packaging: Increase the whiteness and opacity of paper.

- Environmental treatment: Application in water and air treatment systems.

- Plastics and polymers: Coloring and improving the durability of plastic products.

- Paint and coating industry: Increase coverage and color fastness.

See more: Diverse titanium dioxide uses in different industries

In short, TiO2 is a versatile compound with many superior properties, playing an important role in many industries, especially in the production of white pigments. Understanding the structure, properties and applications of TiO2 will help us appreciate its importance in modern life, and open up new possibilities in the development and application of this material in the future.

2. Benefits of TiO2 for White Masterbatch

TiO2 plays an important role in creating and improving the quality of white masterbatch. Here are the main benefits that TiO2 brings to white masterbatch:

2.1. High Versatility

TiO2 can be used in many different types of white pigments, serving diverse applications such as: Paints and coatings, Plastics and polymers, Paper and packaging, Cosmetics and personal care, Food and pharmaceuticals, etc. It can be said that TiO2 is a versatile active ingredient when it becomes an important ingredient in many different industries.

2.2. Protection from UV Rays

TiO2 has the ability to effectively absorb UV rays, helping to protect white pigments and surrounding materials from the harmful effects of sunlight, specifically:

- Preventing decomposition and discoloration caused by UV rays

- Extending product life when used outdoors

- Protecting other ingredients in the product formula

2.3. Improved Dispersion

TiO2 has a small and uniform particle size, helping to improve the dispersion ability in different substrates; Offering several advantages:

- Creates more uniform color

- Improves gloss and surface texture

- Increases efficiency, reduces the amount of pigment needed

2.4. Fire Resistance

TiO2 has natural fire resistance properties, which helps improve the fire resistance of products containing white pigments. This is especially important in industrial applications such as: Construction materials, Plastics and polymers, Industrial paints, etc.

2.5. Enhances Color Fastness

Thanks to its stable structure, TiO2 helps white pigments maintain their color for a long time, even when exposed to environmental factors such as sunlight, high temperatures, humidity or chemical agents. Extending the product's lifespan, this reduces the need/cost of maintenance and replacement.

2.6. Enhanced Mechanical Strength

When used in applications such as plastics or paints, TiO2 not only provides color but also contributes to enhancing the mechanical strength of the product, specifically:

- Increased impact resistance

- Improved hardness and abrasion resistance

- Helps the product withstand harsher conditions of use

2.7. Enhanced Whiteness and Brightness

TiO2 has a high refractive index, allowing it to reflect almost all visible light, helping to create a bright, pure and uniform white effect. This ability makes TiO2 the top choice in creating white products or increasing the brightness of other colors.

3. Conclusion

TiO2 is a crucial component in producing and enhancing white masterbatch, offering numerous benefits such as safety, increased whiteness and brightness, mechanical strength, color fastness, flame resistance, improved dispersion, UV protection, and high versatility.

These properties make TiO2 an essential ingredient in the production of white pigments for various industries. However, it's crucial to adhere to regulations and safety guidelines to optimize efficiency and protect both users and the environment.

As technology progresses, we anticipate advancements in TiO2 production and application, leading to innovative, high-quality, safe, and eco-friendly products.

4. About EuroPlas White Masterbatch

EuroPlas is proud to introduce a high-quality white masterbatch product line, specially designed to meet the diverse needs of customers in many industrial fields. With the perfect combination of advanced technology and high-quality raw materials, EuroPlas products not only bring outstanding color performance but also ensure long-term stability and durability for the final product.

4.1. Basic Information

- Color: White

- Packing: 25kg/bag

- Base resin: Polyethylene

- Granule size: 3 mm ± 0.3 mm

- Storage: Keep in dry conditions

- Additives: Dispersant, processing aid

- Certified safe for contact with food according to European standards Eu.No10/2011 and 1282/201.

4.2. Classification

EuroPlas offers a wide range of white masterbatches with different pigment contents, from 20% to 70%, to meet all production needs:

- EMPE 1020: 20% white masterbatch

- EMPE 1030: 30% white masterbatch

- EMPE 1040: 40% white masterbatch

- EMPE 1050: 50% white masterbatch

- EMPE 1060: 60% white masterbatch

- EMPE 1070: 70% white masterbatch

- Bio White: 40% white masterbatch (environmentally friendly version)

4.3. Outstanding Features

EuroPlas white masterbatch products are a sophisticated combination of high-grade Titanium Dioxide, virgin polyethylene base resin and special additives. This formula ensures bright white, opacity and transparency according to the specific requirements of each customer. Using a mixture of high-quality TiO2 in both rutile and anatase forms, with a ratio of 20% to 75%, EuroPlas's white masterbatch products not only meet the most stringent color requirements but also act as a protective shield, helping plastic pellets resist harsh environmental impacts, especially UV radiation.

Thanks to the above outstanding features, EuroPlas's white masterbatch not only meets but also exceeds customers' expectations for a high-quality, versatile and environmentally friendly product. We are committed to constantly innovating and improving our products to always be at the forefront of white masterbatch production, accompanying the development of the global plastics industry.

See more: The advantages and uses of white masterbatch across industries

EuroPlas is proud to be a pioneer in the field of filler masterbatch production. With years of industry experience, EuroPlas is committed to delivering superior products that meet the highest standards of quality, safety, and environmental responsibility. We are dedicated to providing top-quality products and exceptional customer service, making us a trusted partner for businesses across various industries. Contact EuroPlas's team of consultants today via hotline or email, or leave your information on the form for prompt and accurate support.