When it comes to flame retardant compounds, EuroPlas stands out with its diverse product offerings tailored to meet industry needs. Specializing in formulations that comply with international fire safety regulations, EuroPlas ensures that its compounds effectively inhibit flame propagation, making them suitable for various sectors, including textiles, construction, and electronics. The company's commitment to quality means that each flame retardant compound is rigorously tested for thermal stability and effectiveness, providing peace of mind to customers.

When it comes to flame retardant compounds, EuroPlas stands out with its diverse product offerings tailored to meet industry needs

1. Overview Of Flame Retardant Compound

Flame retardant compounds are specialized chemical substances added to materials to reduce their flammability and delay the spread of fire. These compounds can be incorporated into a wide range of materials, including plastics, textiles, wood, and paints, to enhance their fire resistance.

Their development began in ancient times when people realized that certain chemicals could reduce the combustibility of materials. One of the earliest documented uses was by the Egyptians, who treated wood with alum to slow down combustion. In the 19th century, early forms of fireproofing agents were developed to protect buildings, electronics, etc. Over time, advancements in chemistry and materials science have led to the creation of more effective and diverse flame retardant compounds.

Flame retardants are typically classified into two main categories:

- Additive flame retardants: These compounds are added to materials during the manufacturing process. They work by disrupting the combustion process and preventing the formation of flammable gas.

- Reactive flame retardants: These compounds are chemically bonded to the material during manufacturing, making them more resistant to leaching and degradation.

2. A List of EuroPlas’ Flame Retardant Compounds

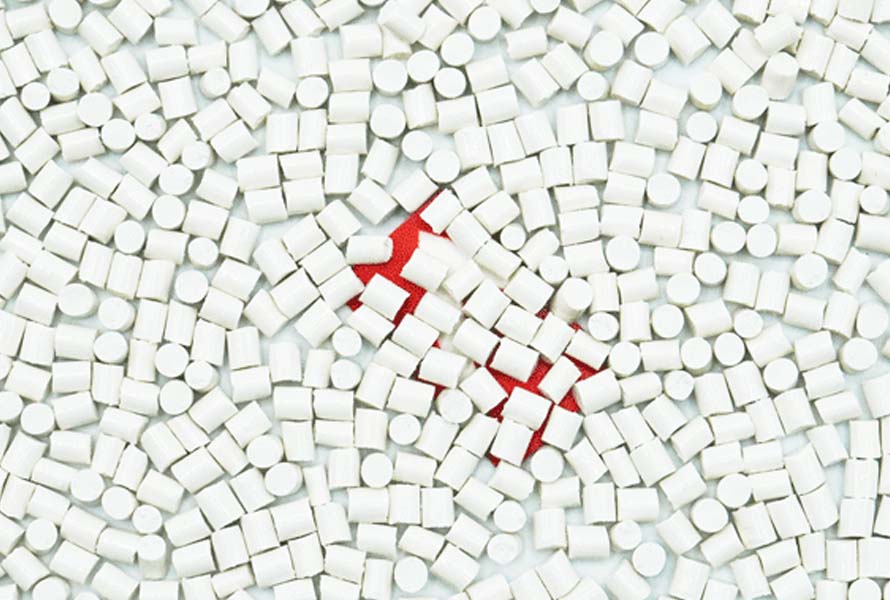

EuroPlas offers a range of high-performance flame retardant compounds designed to meet diverse industrial needs. These compounds are engineered to enhance the fire safety properties of various plastic materials, ensuring compliance with global safety standards across different sectors.

2.1. PP flame retardant compound

Polypropylene (PP) flame retardant compounds are created by blending regular PP resin with specially formulated halogenated or non-halogenated flame retardant additives. EuroPlas offers a range of PP flame retardant compounds that comply with various UL94 fire resistance standards, including 5VA, 5VB, V0, V1, and V2. This allows for tailored fire safety solutions depending on the specific needs of an application.

EuroPlas provides PP flame retardant compounds meeting UL94 international standards

The benefits of PP flame retardant compounds extend beyond enhanced fire resistance. EuroPlas offers these compounds as a complete solution, eliminating the need for separate mixing of resin and flame retardant additives. This simplifies the manufacturing process and ensures consistent material properties.

Additionally, EuroPlas can customize these compounds based on the specific requirements of your finished product. This flexibility allows you to achieve desired mechanical properties in conjunction with enhanced fire safety.

2.2. PC flame retardant compound

PC-FR compound integrate flame retardant additives directly into the PC resin, resulting in a self-extinguishing material that fulfills stringent safety regulations. EuroPlas offers a diverse range of PC flame retardant compounds, encompassing both halogenated and non-halogenated formulations.

This provides manufacturers with the flexibility to choose the option that aligns best with their environmental and performance goals. Additionally, these compounds meet demanding UL94 fire resistance standards, ensuring optimal safety for electronic devices.

PC-FR compounds incorporate flame retardant additives into PC resin for self-extinguishing safety

The advantages of PC flame retardant compounds extend beyond exceptional fire resistance. EuroPlas ensures that these compounds maintain all the desirable properties inherent to PC, including high heat resistance, excellent electrical insulation, and impressive dimensional stability. This comprehensive approach guarantees optimal performance in tandem with superior fire safety.

Furthermore, EuroPlas offers customization options to tailor the PC flame retardant compound to your specific needs. This allows for the creation of a material that not only meets stringent fire safety regulations but also delivers the necessary mechanical and electrical properties for your electronic components.

2.3. HIPS flame retardant compound

High-impact polystyrene (HIPS) flame retardant compounds offer a valuable solution for applications where both fire safety and visual appeal are important. EuroPlas achieves this balance by carefully blending HIPS resin with specifically formulated flame retardant additives.

These additives enhance fire resistance without compromising the inherent qualities of HIPS, such as high impact strength and excellent surface finish. Additionally, EuroPlas offers a diverse range of HIPS flame retardant compounds that comply with various UL94 fire resistance standards such as V0, V1 and V2, allowing users to tailor the level of fire safety to their specific needs.

HIPS flame retardant compounds provide effective fire safety and enhance visual appeal in applications.

The benefits of HIPS flame retardant compounds extend beyond enhanced fire safety and attractive aesthetics. EuroPlas offers these compounds as a pre-mixed solution, eliminating the need for separate mixing of resin and additives. This streamlines the manufacturing process and ensures consistent material properties.

HIPS flame retardant compounds are also prized for their versatility, making them suitable for a wide range of applications in industries such as electronics, automotive, and construction. This combination of fire safety, aesthetics, and efficient production makes HIPS flame retardant compounds an ideal choice for various applications.

2.4. ABS flame retardant compound

ABS (Acrylonitrile butadiene styrene)-FR compounds offer the perfect blend of strength and fire safety. EuroPlas achieves this by incorporating carefully selected flame retardant additives into the ABS resin. These additives effectively hinder the combustion process, enhancing the material's fire resistance without compromising its inherent strengths.

EuroPlas provides a diverse range of ABS flame retardant compounds that comply with various UL94 fire resistance standards including V0, V1, and V2.This allows for tailored safety solutions depending on the specific needs of the application.

ABS (Acrylonitrile butadiene styrene)-FR compounds offer the perfect blend of strength and fire safety.

The benefits of ABS flame retardant compounds go beyond improved fire resistance. These compounds are offered as pre-mixed solutions, eliminating the need for separate resin and additive mixing. This streamlines the manufacturing process and ensures consistency in material properties.

Additionally, EuroPlas offers customization options to tailor the ABS flame retardant compound to your specific needs. This allows you to achieve desired mechanical properties in conjunction with enhanced fire safety, making ABS flame retardant compounds a versatile choice for applications requiring both strength and safety.

2.5. PBT GF-FR compound

Polybutylene terephthalate (PBT) glass fiber reinforced flame retardant (PBT GF-FR) compounds represent a powerful combination of features. EuroPlas creates these compounds by integrating glass fibers and flame retardant additives into the PBT resin.

This results in a high-performance material that offers exceptional mechanical strength, dimensional stability, and superior fire resistance. EuroPlas' PBT GF-FR compounds meet various UL94 fire safety standards (5VA, 5VB, V0, V1, and V2), ensuring they comply with stringent regulations in demanding applications.

EuroPlas' PBT GF-FR compounds combine glass fibers and flame retardants for superior performance.

The advantages of PBT GF-FR compounds extend beyond their impressive safety profile. The incorporation of glass fibers significantly enhances the mechanical properties of the base PBT resin. This translates to increased strength, stiffness, and dimensional stability, making it ideal for applications requiring high structural integrity under challenging conditions.

3. Key Features of EuroPlas Flame Retardant Compounds

EuroPlas flame retardant compounds come with a range of advanced features that make them suitable for various applications. Some of the key features include:

- Superior Flame Retardancy: Designed to prevent the spread of fire, EuroPlas flame retardant compounds meet UL94 international safety standards (V0, V1, V2, etc.), ensuring high levels of fire resistance across industries.

- Thermal Stability: These compounds can endure high temperatures without losing their structural integrity or performance, which is crucial in high-heat environments.

- Mechanical Strength: Despite the inclusion of flame retardant additives, the compounds maintain excellent mechanical properties like durability, impact resistance, and flexibility.

- Material Versatility: EuroPlas provides flame retardant compounds for different plastic types, including PP, PC, HIPS, ABS, and PBT GF. This caters to a wide range of applications across various industries, such as electronics, automotive, and construction.

- Pre-Mixed Solutions: Offers flame retardant compounds as pre-mixed solutions, eliminating the need for separate resin and additive mixing. This streamlines the manufacturing process and ensures consistent material properties.

- Customization Options: EuroPlas allows for customization of flame retardant compounds to meet specific requirements. This allows for achieving desired functionalities alongside fire safety.

- Compliance with Regulations: EuroPlas flame retardant compounds comply with stringent fire safety regulations, ensuring the safety of finished products.

EuroPlas flame retardant compounds can endure high temperatures without losing their structural integrity or performance

4. Applications of EuroPlas’ Flame Retardant Compounds

EuroPlas' flame retardant compounds find application in a wide range of industries due to their ability to enhance fire safety while maintaining material performance. Here are some key application areas:

- Electrical and Electronics: Used in components like connectors, cables, switchgear, and circuit breakers to enhance fire safety and prevent electrical.

- Automotive: Parts exposed to potential heat sources, such as dashboards, interior components, and wiring harnesses, benefit from EuroPlas' flame retardant compounds. This improves overall vehicle safety and complies with stringent automotive fire safety regulations.

- Construction: Construction materials like insulation, cable trays, conduits, and structural components require fire resistance. EuroPlas offers solutions for these applications, enhancing building safety and meeting fire safety codes.

- Home Appliances: Appliances like washing machines, refrigerators, and toasters can utilize EuroPlas' flame retardant compounds in their housings and internal components. This ensures the safety of household appliances and reduces fire risks.

- Consumer Goods: Many consumer goods, such as toys, furniture components, and luggage, can benefit from the fire safety boost offered by EuroPlas' flame retardant compounds. This provides peace of mind to consumers and helps manufacturers comply with safety regulations.

EuroPlas flame retardant compounds boost safety in various industries, preserving material performance

By offering a wide range of flame retardant compounds with different properties and customization options, EuroPlas helps manufacturers across diverse industries enhance the safety, ensure optimal performance and fire safety.

5. Conclusion

To sum up, EuroPlas stands out as a trusted provider of innovative flame retardant compounds. Incorporating EuroPlas' flame retardant compounds into your manufacturing process offers a wealth of benefits. Their primary function, of course, is to significantly enhance fire safety, ensuring your products comply with regulations and prioritize user safety. However, EuroPlas goes beyond just fire safety. Their commitment to maintaining material performance eliminates the need for performance compromises. This translates to products that retain their essential properties, delivering optimal functionality in your end-use applications.

Furthermore, EuroPlas offers pre-mixed solutions, streamlining your manufacturing process. This eliminates the need for separate resin and additive mixing, reducing production time and minimizing potential errors. Additionally, EuroPlas provides customization options, allowing you to tailor the flame retardant compound to your specific needs. This ensures optimal performance and avoids the need for additional materials or adjustments.

Ultimately, EuroPlas flame retardant compounds offer a cost-effective and reliable solution. They enhance safety, maintain performance, streamline your process, and can be customized to your needs. For further inquiries, contact EuroPlas today.