Acrylic and polycarbonate are two common types of transparent thermoplastics used in a wide range of applications. While it can be difficult to distinguish between these products by their appearance, there are also some key differences that set them apart. Which is stronger, acrylic or polycarbonate? Let’s dive into the comparison in the article below.

I. Acrylic vs polycarbonate applications

1. Properties of acrylic and polycarbonate

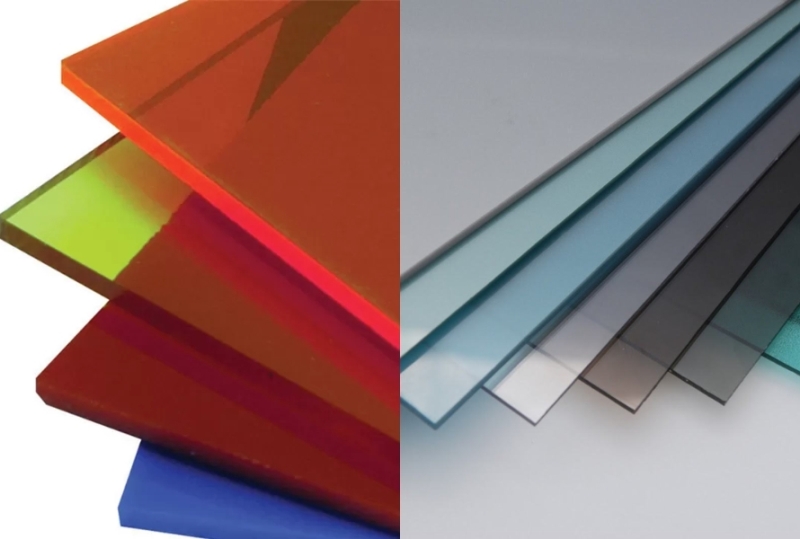

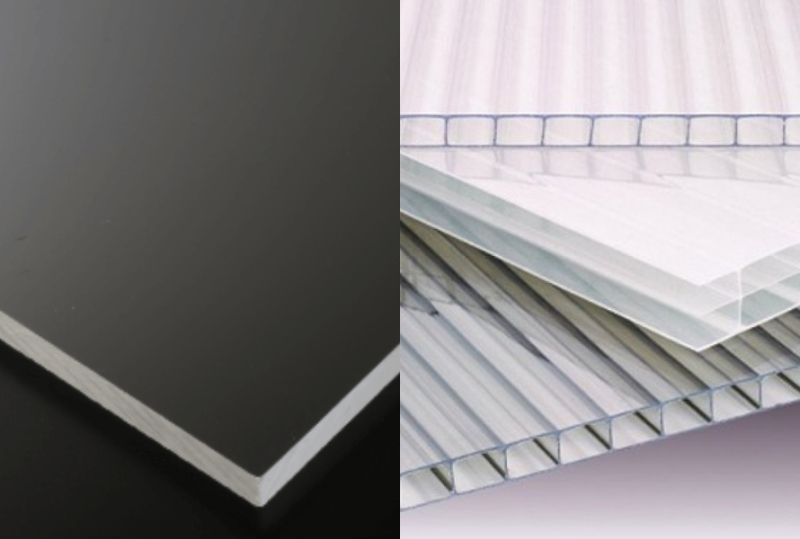

Acrylic, also known as polymethyl methacrylate (PMMA), is a transparent thermoplastic that is lightweight and shatter-resistant. It has a high tensile strength, good optical clarity, and is resistant to weathering and aging.

Polycarbonate, on the other hand, is a thermoplastic that is known for its impact resistance and high strength. It is also lightweight and has good optical properties.

2. Applications of acrylic vs polycarbonate

Acrylic and polycarbonate have various properties that are beneficial for the end products. Therefore, both plastics are the key material of a wide range of applications in many industries. Some of which are fairly similar, and others which are very different.

Acrylic is recommended for applications requiring highly clear, lightweight material or a certain size or shape because it is easily molded without affecting visibility. When strength and impact resistance is required, or when the material might be subjected to intense heat, polycarbonate is preferable.

It's important to spend time comparing the two plastics side by side thoroughly to choose the best material for your project. This might help you decide which is ideal for your particular job.

Yet, choosing the best plastic should be simple, depending on what you plan to use acrylic or polycarbonate for. These are some typical uses for these two polymers to help you in making the appropriate decision.

| Acrylic Applications |

Polycarbonate Applications |

- Furniture

- Windows and glass substitutes

- Medical technologies and implants

- Indoor and outdoor signage

- Insulations

- Light covers

- Retail displays

- Craft projects

- Residential & commercial aquariums

- Motorcycle helmet visors

- Police riot control vehicles

- Hockey rink glass

- LED-diffusing lighting panels

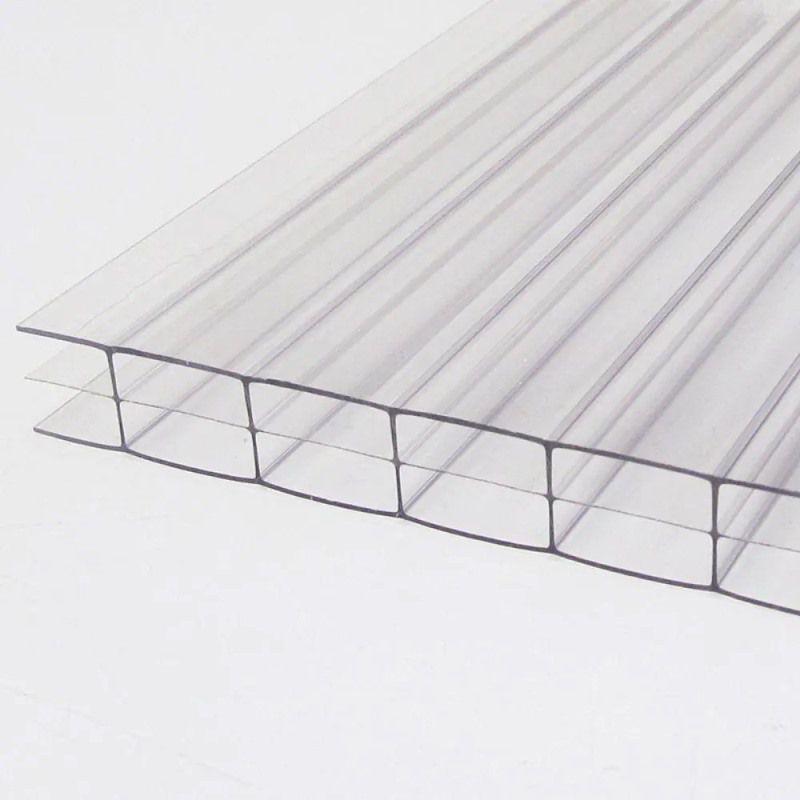

- Architectural glazing, skylights

|

- Construction materials

- Bullet-resistant windows and doors

- Greenhouse windows

- Electronic components

- Clear molds for casting

- Roofing panels

- Reusable drinking bottles

- Sports equipment

- Outdoor Signs

- Sun-glass/eyeglass lenses

- Riot shields

- Compact discs and DVDs

- Face shields

- Machine guards

|

II. Acrylic vs polycarbonate cost

Both polycarbonate and acrylic are less expensive than glass and other engineering materials, making them an affordable option for homeowners and building contractors. However, when it comes to the difference between acrylic and polycarbonate cost, the cost of acrylic sheets is less expensive and more affordable than polycarbonate.

Polycarbonate sheets are around 35% more expensive than acrylic plastic. This is because acrylic is easier to manufacture and has been in production for a longer time than polycarbonate. The average cost per kilogram of polycarbonate sheet is approximately $2.50 - $3.50, while the price of acrylic sheet is about $1.00-2.00.

The difference in cost depends on the product form and grade of the materials. Even if polycarbonate could consume a large budget of your development or project, the properties that drive up its price could be a wiser long-term investment.

III. Acrylic vs polycarbonate recyclability and sustainability

1. Recyclability

Both acrylic and polycarbonate are thermoplastic, making them both recyclable and processable. These materials can be remelted and molded numerous times; however, the quality degrades with each repetition. These materials also can be shredded and used as fillers for other polymers.

Compared to polycarbonate, acrylic is far more flexible and simple to recycle when it comes to recyclability. It can be remelted and recast to create new building materials without much degradation.

On the other hand, because of the presence of Bisphenol A (BPA), polycarbonate can only be reshaped and reused in a limited number of applications. When soaked in water or at high temperatures and humidity levels, BPA has been proven to leak from the product. BPA usage is restricted or prohibited in various countries because it is considered potentially dangerous for consumers' health. Therefore, polycarbonate is not advised for use in food and beverage containers.

2. Sustainability

In terms of sustainability, compared to an identical amount of glass, the production of polycarbonate and acrylic consumes significantly less heat and energy. Because polymer materials can be recycled far more readily than glass, their energy costs can be dispersed across a variety of uses over the course of their lifetime.

Like all plastics, neither acrylic nor polycarbonate decomposes over time. If the plastics are not disposed of correctly, they can accumulate in landfills and enter waterways. It is essential to recycle and dispose of these products properly to minimize negative environmental effects.

IV. Acrylic vs polycarbonate uv resistance

1. UV Resistance and Light transmission

Exposure to ultraviolet (UV) light can cause plastics to degrade over time. This degradation can result in discoloration, brittleness, and loss of strength and flexibility.

Both acrylic and polycarbonate offer better clarity than glass, letting in more light. Acrylic has exceptionally high UV resistance. It can block up to 98% of UV rays. It also resists yellowing from the sun and gives better clarity than glass transmitting 92% of light.

This property makes it a perfect alternative to glass windows, where strength is key. This quality also makes it ideal for outside signage, where constant UV exposure can quickly damage the print underneath.

Polycarbonate offers a light transmission of 88%, yet it is not effectively UV-resistant. This material can become slightly yellow after being exposed for a long period of time.

However, polycarbonate's light-diffusing qualities are advantageous for greenhouse applications because direct sunlight can burn plants. And if companies want to use polycarbonate in their products, they can significantly improve its UV resistance with UV stabilizers.

2. Clarity

In terms of optical clarity, both acrylic and polycarbonate offer good transparency, but acrylic is generally considered to be more optically pure. It also has a higher refractive index than polycarbonate because it can transmit more light and create a more brilliant display.

V. Acrylic vs polycarbonate chemical resistance

Chemical resistance is a crucial factor to consider when choosing a plastic material for different applications. If you're looking for a plastic material that can withstand exposure to various chemicals, then acrylic and polycarbonate are two popular options to consider.

Polycarbonate has excellent chemical resistance to many types of chemicals, including acids, bases, and some organic solvents. However, polycarbonate is not suitable for exposure to some chemicals, such as chlorinated hydrocarbons, ketones, and aromatic hydrocarbons. These chemicals can cause the material to degrade over time, leading to discoloration, cracking, or even failure.

Generally, chemical laboratory solutions, including water as the solvent, do not affect acrylics. Acrylic is resistant to most acids, bases, salt solutions, alkalis, detergents, dilute inorganic acids, and aliphatic hydrocarbons.

Acrylic is not suitable for applications that require exposure to strong solvents or chemicals such as acetone, benzene, and toluene. When exposed to these chemicals, it can cause discoloration and surface hazing on the acrylic surface.

VI. In a nutshell, which is stronger, acrylic or polycarbonate?

When it comes to tensile and flexural strength, acrylic is generally considered to be stronger than polycarbonate. Acrylic has a higher tensile strength, meaning it can withstand more pulling force without breaking, and higher flexural strength, meaning it's less likely to bend or deform under load.

However, when it comes to impact strength, acrylic is not as impact-resistant as polycarbonate. Acrylic can crack or shatter upon impact, which makes it less suitable for applications where impact resistance is critical.

Polycarbonate has an incredibly high impact strength, making it virtually unbreakable in many applications. In addition, it can withstand extreme temperatures, ranging from -40°C to 120°C, without breaking or cracking. This is why polycarbonate is often used in safety glasses, riot shields, and other protective gear.

Therefore, when considering cost, recyclability and sustainability, UV resistance, as well as tensile and flexural strength, acrylic is stronger. On the other hand, polycarbonate is the ideal material for products that require high-impact resistance.

Overall, acrylic and polycarbonate have unique properties and advantages that make them suitable for various applications. It's important to understand these materials differences to choose the right one for the products.