Plastic recycling is an essential but intricate puzzle, with some plastics seamlessly joining the recycling stream, while others encounter barriers. From the chemical composition to contamination concerns, this blog explores the factors influencing a plastic's recyclability.

We'll unravel the nuances of PET, HDPE, PVC, and more, shedding light on the journey from consumption to recycling bin. Join us on this exploration as we decode the intricacies that determine which plastics qualify for recycling, why can't some plastics be recycled and why it matters in our collective effort for a greener, more responsible world.

1. Brief overview of the importance of plastic recycling

In our modern world, plastic plays a pivotal role in our daily lives due to its durability and versatility. However, the significance of plastic recycling is often hindered by the confusion surrounding which plastics are recyclable.

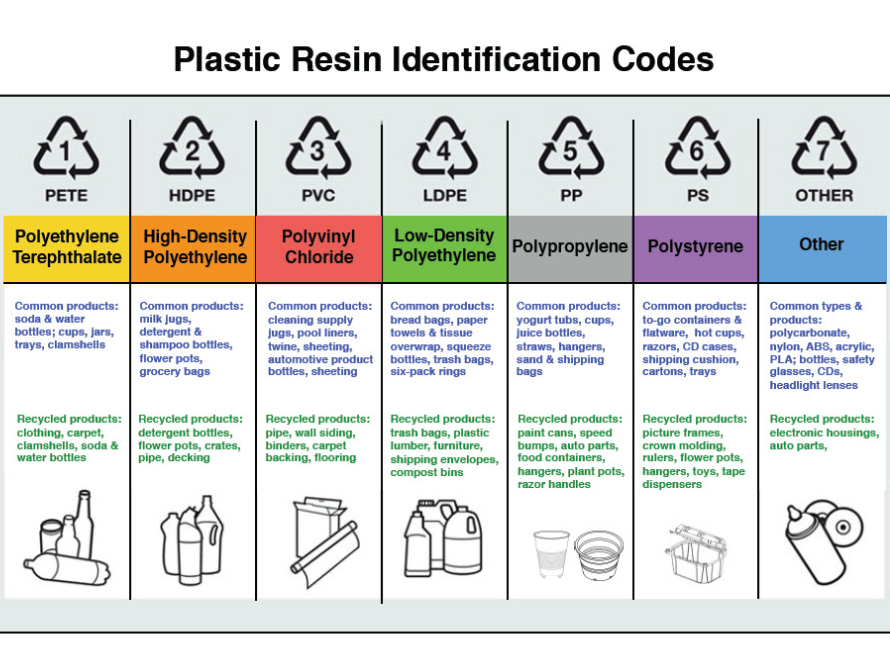

This confusion arises from the various resin identification codes (RIC) found on plastic items, denoting different types of plastics such as PET, HDPE, PVC, and more.

Consumers, faced with these codes, may struggle to understand the associated recycling guidelines, leading to unintentional misplacements of non-recyclable plastics in recycling bins. This misinterpretation can contaminate recycling streams, posing challenges for municipal recycling facilities tasked with sorting and processing recyclables.

The consequences extend beyond individual actions, affecting the overall efficiency of recycling programs. Contaminated batches diminish the quality of recycled materials, undermining the sustainability goals of recycling initiatives.

To address this issue, clear and standardized labeling, along with educational efforts, is essential. Empowering consumers with the knowledge to make informed choices about plastic usage and disposal is crucial.

By fostering awareness and understanding of recyclability criteria, we can collectively contribute to a more effective plastic recycling system, reducing the environmental impact of plastic waste on our planet.

Read more: How Is Plastic Recycled?

2. Types of Plastics

Understanding the various types of plastics is crucial for effective recycling. Plastics are categorized into different groups based on their chemical composition, making it essential to distinguish between them to determine their recyclability.

The identification of common recyclable and non-recyclable plastics is essential for consumers and recycling facilities alike. Additionally, recycling symbols and resin codes play a significant role in conveying information about the recyclability of plastics.

Read more: How Is Plastic Recycled?

2.1 Explanation of Different Types of Plastics

Plastics are broadly classified into several types, each with its unique properties and applications. Here are some of the most common types:

- PET (Polyethylene Terephthalate): Commonly used in beverage bottles and food packaging, PET is widely recyclable. It's known for its clarity and lightweight nature.

- HDPE (High-Density Polyethylene): Found in milk jugs, detergent bottles, and some plastic bags, HDPE is highly recyclable. Its sturdiness and resistance to chemicals make it a favorable material.

- PVC (Polyvinyl Chloride): PVC is commonly used in pipes, cables, and construction materials. It poses challenges for recycling due to the release of harmful chlorine during processing. As a result, PVC is often not accepted in recycling programs.

- LDPE (Low-Density Polyethylene): Used in plastic bags, shrink wrap, and various containers, LDPE is less commonly recycled through curbside programs. However, some facilities accept it for recycling.

- PP (Polypropylene): Found in yogurt containers, bottle caps, and packaging, PP is becoming more widely accepted in recycling programs due to increased demand for this versatile plastic.

- PS (Polystyrene): Commonly known as Styrofoam, PS is lightweight and often used in packaging materials. However, it is challenging to recycle, and many recycling programs do not accept it.

2.2 Identification of Common Recyclable and Non-Recyclable Plastics

Recyclability depends on the type of plastic and local recycling capabilities. Generally, PET, HDPE, and some PP containers are types of recyclable plastics and widely accepted in recycling programs. On the other hand, PVC and PS are often excluded due to recycling challenges and environmental concerns.

Before discarding plastics, check with local recycling guidelines to determine which types are accepted. Avoid placing non-recyclable plastics in recycling bins, as this can contaminate the recycling stream and hinder the recycling process.

2.3 Recycling symbols and resin Codes

To help consumers identify the type of plastic used in a product, recycling symbols and resin codes are used. These symbols, often displayed as a number within a triangle of arrows, provide information about the resin used in the item. Here are some common symbols:

- PET (#1): Found in beverage bottles and food containers.

- HDPE (#2): Used in milk jugs, detergent bottles, and containers.

- PVC (#3): Commonly found in pipes and construction materials.

- LDPE (#4): Used in plastic bags, shrink wrap, and squeezable bottles.

- PP (#5): Found in food containers and bottle caps.

- PS (#6): Used in foam products and disposable food containers.

- Other (#7): Represents various other plastics, including composites.

3. Factors influencing recyclability:

Recycling plastics is a complex process influenced by several factors. Understanding these factors is crucial in comprehending why some plastics are recyclable, while others are not.

3.1. Material composition

The chemical composition of plastics plays a significant role in their recyclability. A few types of recyclable plastics like PET and HDPE have straightforward molecular structures, making them easier to process and recycle. On the other hand, complex compositions, such as those found in certain types of composites, make recycling more challenging.

3.2. Contamination

Contamination is a major obstacle to effective recycling. Plastics contaminated with food residues, chemicals, or other non-recyclable materials can compromise the entire recycling stream. Proper cleaning and separation of recyclables at the source are crucial to maintaining the quality of materials.

3.3. Product design

The design of plastic products greatly influences their recyclability. Factors such as the use of multiple materials, intricate shapes, or excessive labeling can make recycling more difficult. Designing products with recyclability in mind, including easily separable components, helps streamline the recycling process.

3.4. Local recycling capabilities

The infrastructure and capabilities of local recycling facilities play a pivotal role in determining which plastics can be recycled.

Some facilities may lack the technology to process certain types of plastics, while others may have limited markets for specific recycled materials. The availability of recycling programs and the types of plastics they accept vary from region to region.

3.5. Market demand for recycled materials

The demand for recycled materials in the market directly influences the recyclability of certain plastics.

Plastics with higher market demand, such as PET and HDPE, are more likely to be recycled. Limited demand for certain plastics may discourage recycling efforts, even if the materials are technically recyclable.

3.6. Economic viability

The economic feasibility of recycling specific plastics is a critical factor. Some plastics may be technically recyclable but require additional processing or incur higher costs, making recycling economically unviable. This can result in certain plastics being excluded from recycling programs.

3.7. Regulatory environment

Government regulations and policies also impact the recyclability of plastics. Some regions have stringent recycling mandates, encouraging the recycling of specific plastics, while others may have more relaxed regulations. The regulatory framework can influence the prioritization of certain plastics in recycling programs.

4. Challenges in plastic recycling:

While recycling is a crucial component of sustainable waste management, the plastic recycling industry faces several challenges that impact its effectiveness. Understanding these challenges is essential to developing solutions and improving overall recycling rates.

4.1. Mixed materials and contamination

One of the primary challenges in plastic recycling is the prevalence of mixed materials and contamination. Products often consist of different types of plastics or include non-recyclable components. Additionally, contamination from food residues or other substances can reduce the quality of recycled materials, making them less desirable for manufacturers.

4.2. Complex composites

Certain plastic products are composed of complex combinations of materials, making it difficult to separate and recycle them effectively. These composites pose a challenge for recycling facilities, as the separation process becomes intricate and may not be economically viable.

4.3. Lack of standardized recycling codes

The absence of standardized recycling codes on plastic products complicates the sorting process. While resin codes (1-7) provide some information, they don't address specific recycling requirements or processes. Standardized labeling could help consumers and recycling facilities better identify and handle different plastics.

4.4. Limited market demand for some plastics

The recyclability of plastics is closely tied to market demand for recycled materials. Some types of plastics face limited demand in the manufacturing sector, reducing the economic incentive for recycling. This lack of demand can lead to certain plastics being excluded from recycling programs.

4.5. Technological limitations

Advancements in recycling technology are essential for effectively processing a wide range of plastics. However, some plastics may require sophisticated technologies that are not universally available. Lack of access to advanced recycling equipment can hinder the recycling of certain materials.

4.6. Consumer awareness and behavior

Effective recycling requires active participation from consumers, including proper sorting and disposal of plastic waste. Lack of awareness about recycling practices, confusion over recyclability, and improper disposal contribute to challenges in the recycling stream.

4.7. Globalization of the plastics market

The global nature of the plastics market complicates recycling efforts. Plastics are often manufactured in one region and used in another, leading to inconsistencies in recycling practices. A more cohesive international approach is needed to address these challenges.

4.8. Infrastructure gaps

Insufficient recycling infrastructure in some regions hampers the collection and processing of plastic waste. The lack of recycling facilities and convenient collection points can discourage individuals from participating in recycling programs.

4.8. Economic factors

The economic viability of recycling specific plastics is a critical challenge. Some recycling processes may be expensive, making it challenging to compete with the production of new plastics. Economic factors influence the decision to recycle or dispose of certain plastics.

Read more: How Is Plastic Recycled?

5. Conclusion:

In the realm of recyclable plastics, challenges like mixed materials and the lack of standardized infrastructure underscore the need for a comprehensive solution. As we strive for sustainability, consumer education, technological advancements, and global collaboration emerge as crucial elements.

By comprehending the intricacies of plastic recyclability, we pave the way for informed choices and sustainable practices, contributing to a healthier planet for current and future generations. Together, let's shape a future where every plastic finds a purpose in the circular economy.