PA66 is the abbreviation for polymer compound 66 or synthetic resin

PA66 is the abbreviation for polymer compound 66 or synthetic resin. It is made from two monomers, hexamethylenediamine and adipic acid, which are chemically combined to form long chains of repeating units. The current market is recording a high level of PA66 application and is constantly increasing. Currently, PA66 is divided into a variety of different groups based on compound ratio and performance. The following article will provide useful information about common types of PA66 and how to choose a suitable PA66 line for your upcoming project.

1. Six types of PA66

PA66 is divided into a variety of different groups based on compound ratio and performance

Corresponding to the name, PA66 GF60 is a combination of PA66 and 60% glass fiber. At this ratio, PA66 GF60 is strongly enhanced with inherent properties such as hardness, durability, and good elasticity. In addition, PA66 GF60 also demonstrates excellent properties when possessing heat resistance and dimensional stability when operating in harsh environments.

1.2. PA66 GF50

PP66 GF50 is also the result of combining PA66 with 50% glass fiber. This combination also aims to improve the properties of the original material. They also possess basic properties such as strength, flexibility, and good strength. However, in PP66 GF50 stands out with its higher thermal stability and improved thermal stability compared to similar products. Specifically, PP66 GF50 maintains an excellent anti-warping rate even in environments operating under high loads at high temperatures (up to 130°C).

PA66 GF30 is a combination of PA66 and 30% glass fiber (GF 30%). This combination gives the material perfectly improved properties. They possess higher durability, creep resistance, and hardness. In addition, PA66 GF30 possesses numerous excellent mechanical properties and ideal dimensional stability. PA66 GF30 is one of the top choices for applications requiring elasticity, good heat resistance and long-term load balance. The additive of PA66 GF30 is inherently black and enhances long-term external UV protection. Some common applications of PA66 GF30 include car covers, engine covers and some exterior designs.

1.4. PA66 GF35

35% glass fiber has excellent durability and thermal stability combined with PA66, we get PA66 GF35. This material is also considered to have superior hardness than PA66 GF30. Thanks to its outstanding hardness, PA66 GF35 is always the ideal choice for mechanical engineering and aerospace applications. In addition, when using PA66 GF35 plastic, we can choose the size flexibly thanks to its ability to adapt well to extremely diverse extrusion methods into sheets and bars.

1.5. PA66 GF15

The combination of PA66 and 15% glass fiber brings to the manufacturing industry a new material called PA66 GF15. This is a material commonly used in the process of creating thermoplastic structural foam (TSF). The material PA66 GF15 is well adapted to the plastic injection molding process in the production line. This is one of the materials that is considered quite durable and hard but not as strong as materials containing a higher percentage of glass.

1.6. Flame retardant PA66

Flame retardant PA66 plastic is a combination of PA66 plastic and flame retardant. This is a combination that gives the material great properties. Among them, the most outstanding feature of fireproof PA66 is its ability to operate durably in high temperature environments. The reason is thanks to flame retardant additives that have the ability to prevent polymer materials from igniting or inhibit the flame propagation process of the material. This feature makes PA66 one of the materials with impressive performance in harsh thermal environments.

Read more: PA66 GF30 - PA66 30% glass fiber: Outstanding benefits & applications

Read more: Common additives used in PA66 GF

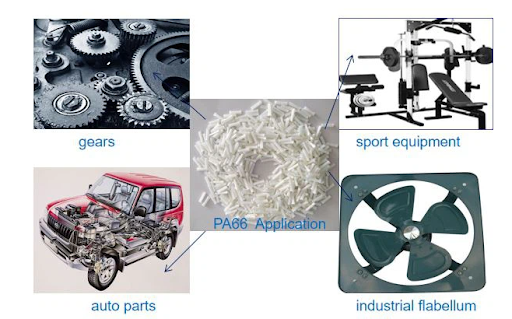

2. Applications of PA66 across industries

PA66 is considered one of the materials with extremely flexible combinations to significantly improve material properties

PA66 is quite commonly used in car manufacturing components. With its durable features and improved stiffness and flexibility, PA66 brings improved components to the automotive industry. In particular, PA66 partly solves the problem of volume, helping to significantly save machine operating materials.

The aerospace industry has successfully applied the constantly improving features of PA66. Thanks to its hardness and ease of shaping, PA66 provides aircraft components with a sturdy, safe cover. In addition, PA66's ability to enhance fire resistance helps it perform well in the role of thermal stability of machinery during flight.

Not stopping at the automotive and aviation technology industries, PA66 also plays a good role in protecting a variety of machinery components. Among them, mechanical equipment that needs to regularly operate in long-term environments such as agricultural machines, industrial production machines and some electronic devices. Possessing durable features, PA66 plastic helps users save maintenance time. In addition, their light weight helps them save energy consumption during operation many times more than metal.

PA66 is very flexible in improving properties such as hardness, impact resistance, abrasion resistance, melt resistance, etc. This makes PA66 always the ideal choice for outdoor applications such as children's play areas, garden design, outdoor furniture, swimming pools, etc. They give users years of durable performance even when operating in harsh weather environments.

Plastics have long been a major contributor to medical devices. In particular, PA66 frequently appears in applications such as medical devices, orthopedic and cardiovascular implants. PA66 contributes to improving the mechanical and heating properties of medical processes.

3. How to choose the right PA66

We need to determine product performance requirements to properly determine suitable PA66

- Based on operating environment

Relying on the operating environment is one of the indispensable things to help us choose the right PA66. Factors to consider such as frequency of impact, temperature requirements, operating environment indoors or outdoors or even underground

- Based on production method

Products can be manufactured and shaped according to many different processes and specifications. To choose the right PA66, we need to consider the product manufacturing process such as injection molding, extrusion, 3D printing, molding, etc. Depending on each production process, we can consider choosing the compatible PA66 line. This contributes significantly to limiting damage and waste of raw materials during the production process.

- Based on performance requirements

To properly determine suitable PA66, we need to determine product performance requirements. Different applications will have different performance requirements such as hardness, elasticity, ductility, heat resistance, and abrasion resistance. These performance requirements are extremely diverse depending on each production plan. Therefore, careful consideration of the product performance requirements will help us choose PA66 that is suitable for the project.

4. Conclusion

In short, PA66 is one of the extremely popular materials in the manufacturing sector. They contribute from the fields of industrial production, engineering, and daily life. Currently, PA66 is considered one of the materials with extremely flexible combinations to significantly improve material properties. Depending on the ratio of reinforcing compound, PA66 plastic is divided into many diverse groups and each group exhibits a specific property. To properly choose PA66, you need to consider factors such as product requirements, operating environment, and production method.

5. About EuroPlas’ PA6-PA66 products

PA66 has lower water absorption but higher temperature resistance, hardness and abrasion resistance

Plastic compound material is one of the pride of EuroPlas. Among them, PA6 and PA6 are two typical PA plastics. PA6, PA66 from EuroPlas have high precision in performance parameters, mechanical durability, and improve long-term usability. PA6 has a comparable melting temperature but is easier to process, less deformable and reasonably priced. PA66 has lower water absorption but higher temperature resistance, hardness and abrasion resistance. With many years of experience in the industry, we understand and are committed to providing customers with optimal and quality raw materials. Please refer to EuroPlas's blog for more useful information! We will help you find the optimal answer for the right material line.

Read more: PA66, PA6 blend compound