In the realm of PA66 GF (glass-filled polyamide 66), various additives are employed to optimize performance and address specific requirements. These additives play a crucial role in enhancing the material's properties, ensuring durability, and meeting diverse application needs.

Read more: What are plastic additives? 8 most common plastic additives in plastic industry

1. What is PA66 GF?

Glass-Filled Nylon, a type of technical plastic, results from the fusion of Nylon compounds with glass fibers. Specifically, PA66-GF, a variant of glass-filled Nylon, utilizes polyamide 66 (PA66) as its fundamental compound. PA66 is alternatively referred to as Nylon 66 or polyhexamethylene adipamide.

PA66, a synthetic polymer renowned for outstanding mechanical and thermal properties, boasts impressive chemical resistance. Its robust and resilient nature renders it indispensable across various applications where its exceptional mechanical and thermal attributes, combined with strong chemical resistance, position it as the ideal material. From industrial applications to everyday use, PA66's versatility shines through in diverse settings.

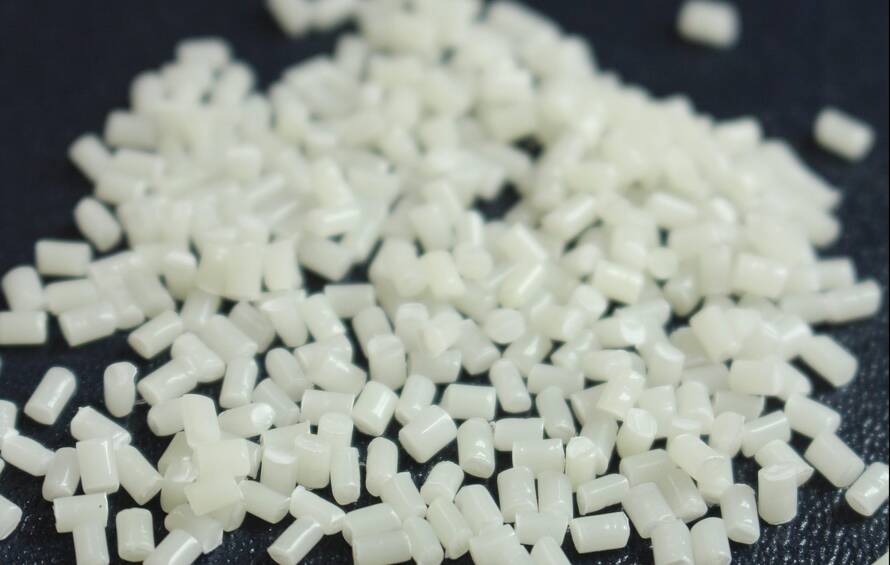

PA66 GF is a type of polyamide 66 (PA66) that is reinforced with glass fiber (GF). Some popular PA66 GF plastic granules include:

- PA66 GF60: PA66 GF60 is a combination of PA66 and 60% glass fiber. This combination enhances the mechanical properties of PA66, especially the tensile strength and elastic modulus, creating a material that is both stronger and stiffer. The use of glass fibers also enhances the thermal properties of PA66, enhancing heat resistance and dimensional stability, making it particularly suitable for applications in high-temperature environments.

- PA66 GF30: PA66 GF30 is a PA66 variant strengthened with 30% glass fiber content. This modification enhances mechanical properties, including increased strength, rigidity, creep strength, and dimensional stability. Ideal for parts enduring high static loads in elevated temperatures over extended periods, this glass-filled modification outperforms unreinforced PA66. However, caution is warranted in sliding applications due to potential abrasive effects from glass fibers on mating surfaces, making Nylon 66 GF30 less suitable for such scenarios.

Read more: PA66 GF30 - PA66 30% glass fiber: Outstanding benefits & applications

- PA66 GF25: The specialized PA66 GF25, featuring glass fiber reinforcement and dry impact resistance, presents an optimal solution for aluminum systems, ensuring superior results.

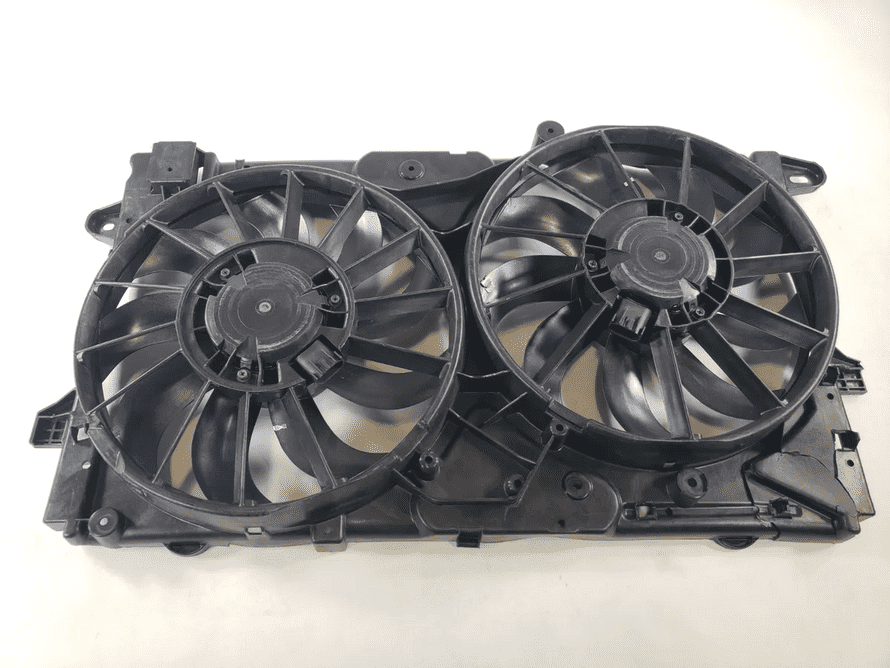

The product made by PA66 GF

2. Common plastics additives used in PA66 GF

2.1. Clarifying additive

Throughout the processing phase for PA66 GF, various factors, including the incorporation of fillers or the utilization of recycled plastic, may compromise the transparency of the product. The deployment of a clarifier emerges as a viable solution to counteract these challenges. This not only heightens product gloss but also presents a cost-effective strategy for manufacturers.

The improved transparency facilitates applications in film production, packaging, household plastics, and more, contributing to both cost savings and enhanced visual appeal.

2.2. Optical brightener

Optical brighteners, specifically tailored for PA66 GF (glass-filled polyamide 66), are employed to counteract yellowing and enhance the whiteness of plastics, inks, coatings, paper, and fiber. In the case of PA66 GF, optical brighteners like OB1 and KSN are suitable additives for achieving the desired brightness and color effects.

2.3. Plasticizers agents

Plasticizers stand as the most widely employed additives in plastics, typically found in the form of non-volatile, colorless liquids. These substances enhance the flow and thermoplasticity of a polymer by reducing the viscosity of the polymer melt. Common plasticizer chemistries encompass citrates, benzoates, ortho-phthalates, terephthalates, adipates, azelates, sebacates, and trimellates.

As relatively non-volatile organic substances, primarily in liquid form, when integrated into a plastic or elastomer, plasticizers contribute to:

- Flexibility: They impart greater flexibility and softness to the product.

- Extensibility: The plastic or elastomer becomes less prone to breakage, especially at cold temperatures.

- Processability: Plasticizers facilitate and ease the processing of the material, making it more malleable during manufacturing.

2.4. Desiccant additive

A desiccant is a hygroscopic substance that plays a crucial role in maintaining a dry state, contrasting with humectants that promote moisture retention. Desiccants effectively eliminate humidity from the air by absorbing moisture, ensuring a consistently dry and moisture-free environment. The presence of moisture can lead to damage in various products such as electronics, apparel, cosmetics, medications, and vitamins, necessitating a dry atmosphere for preservation.

Moist conditions can foster the growth of bacteria, mold, and fungus, causing degradation. In electronics, moisture can result in permanent damage and corrosion, making desiccants essential in preventing such issues.

2.5. Flame retardant

Flame Retardant additives

Combustion can occur when a substance is heated to its flammable temperature in the presence of oxygen. Flame retardants are typically formulated to offer a specific degree of resistance to ignition or the spread of flames. This is achieved by various mechanisms, such as reducing oxygen availability, promoting the buildup of char at the material's surface, inhibiting combustion reactions within the flame zone, or employing other mechanisms.

For halogen-free flame retardants specifically designed for PA66 GF (glass-filled polyamide 66), aluminum diethyl phosphinate (ADP) and MPP come highly recommended. MCA is also a viable option as a flame retardant for non-glass fiber-reinforced polyamide.

Besides, a combination of brominated flame retardants and antimony trioxide is commonly employed as halogen flame retardants. This strategy ensures effective flame-retardant properties in glass-filled polyamide 66 formulations.

2.6. Heat stabilizer agents

Stabilizing agents, including mercaptoethanol and EDTA, along with MAO and COMT inhibitors such as pargyline and pyrogallol, were introduced into the reaction mixture. This addition served the purpose of safeguarding both the substrate and the resulting product from potential spontaneous or enzymatic degradation during the incubation period.

Various types of heat stabilizers, including polyamide, amine, phenolic, organic and inorganic phosphates, copper salt-based, and iodide-based stabilizers, can be employed in polyamide applications. Blends of these stabilizers are often utilized to achieve diverse performance characteristics in polyamide.

2.7. Antioxidant

Incorporating antioxidants for PA66 GF is a common practice to enhance product shelf life and augment high-temperature stability, providing an added stability margin during thermal processing.

Antioxidants such as BX AO 1098 and BX AO 168 serve as general-purpose options for PA66 GF, while BX AO 626, 627, and 9228 are utilized as high-performance antioxidants specifically designed for PA66 GF applications.

2.8. UV stabilizers

UV stabilizers

UV stabilizers, specifically formulated for PA66 GF (glass-filled polyamide 66), encompass two main categories: Ultraviolet Light Absorbers (UVA) and Hindered-Amine Light Stabilizers (HALS).

These stabilizers can be applied individually or in blends. UVA serves to filter harmful UV light, preventing color change and delamination in coatings, adhesives, and sealants. HALS functions by trapping free radicals, effectively preserving surface properties like gloss and preventing issues such as cracking and chalking in paints.

The synergistic combination of these two stabilizer families is highly effective. Notably, UV stabilizers like BX UV 329, BX UV 234, and BX UV 312 are suitable for use in PA66 GF applications.

2.9. Compatibilizer & Impact modifiers

Compatibilizers and impact modifiers tailored for PA66 GF (glass-filled polyamide 66) play a crucial role in enhancing the durability of molded or extruded plastics, particularly those subjected to constant impact forces, such as in cold weather conditions. These additives are introduced into compounded materials to impart specific performance features.

For PA66 GF applications, substances like POE-G-MAH and EPDM-G-MAH are utilized as compatibilizers and impact modifiers. These additives contribute to the strength and break resistance of the product, providing both durability and rigidity to prevent wrapping or sagging during everyday use.

2.10. Lubricants agents

Lubricants, particularly tailored for PA66 GF (glass-filled polyamide 66), are additives designed to enhance processing and aesthetic qualities in polymer applications. These lubricants serve the purpose of minimizing friction, enhancing fluidity, facilitating mold release during the processing of resin or compounds, and contributing to a smoother surface finish of the final products. In the context of PA66 GF, examples of suitable lubricants include EBS and PETS.

2.11. Colorants

Colorants play an important role in giving color to polymers, plastics, coatings, inks, and fibers, creating the aesthetics of various products. Used for polyamide 66 applications with glass fibers (PA66 GF), the colorant must exhibit exceptional thermal stability and chemical resistance to withstand the highly reducing environment of molten PA during draw dyeing. yarns.

Spin dyeing temperatures range from 250 to 290°C, depending on the type of polyamide. Similar to polyester extrusion, only a limited number of colorants are suitable for this purpose.

2.12. Nucleating agent

Nucleating agents, also known as clarifying agents, play a crucial role in enhancing the crystallization of semi-crystalline polymer applications. BX NA 101 and BX NA 102 serve as effective nucleating agents for PA66 GF, providing comparable performance to products from Clariant.

3. Conclusion

In conclusion, the judicious selection and incorporation of these additives are instrumental in unlocking the full potential of PA66 GF, enabling its widespread use across diverse industries. These additives collectively contribute to the material's strength, aesthetics, and overall functionality in various applications.

Polyamide-6 (PA6) and Polyamide-66 (PA66) stand as exemplary engineering thermoplastics, prized for their stiffness, strength, and heat resistance. When fortified with reinforcing agents like glass fiber, glass beads, or talc, these polymers attain even higher levels of performance.

PA66 and PA6 glass fiber compounds, comprising a blend of PA resin and glass fiber reinforcement, exhibit outstanding characteristics. This includes exceptional toughness, wear resistance, chemical resistance, high heat deflection temperature, and mechanical strength. Moreover, the material maintains stability, and electrical insulation properties, and facilitates ease of molding.

PA66, PA6 Glass fiber compound at EuroPlas

EuroPlas' PA66 and PA6 compounds, enriched with 30-50% glass fiber content, find widespread utility in the fabrication of gears, bearings, drive belts, carburetor components, computer elements, and household electrical components. Noteworthy features of these compounds include:

- All-in-one functionality in a single material

- Direct processability without additional materials

- Tailor-made to meet specific end-product requirements

- Increased stiffness, reduced shrinkage, and enhanced strength for PA66 and PA6 resins

- Improved impact resistance and thermal durability for end-products

Besides PA66, PA6 Glass fiber compound, we also offer lots of plastic additives such as clarifying additive, optical brightener additive, odor removing additive, flame retardant, anti-UV additive, anti-aging additive, anti-blocking additive… With more than 15 years in manufacturing and distributing plastic additives, EuroPlas always attempts to provide customers with the best quality products.

Contact us now if you are looking for a qualified supplier for plastics and additives.