Low friction plastics have revolutionized multiple industries, offering materials that are not only durable but also reduce friction in mechanical systems. These plastics are essential in a wide range of applications, from machinery components to automotive parts, where minimizing wear and tear is crucial for increasing longevity and efficiency. Understanding the types of low friction plastics available, along with their benefits and potential drawbacks, can help in selecting the right material for your specific application.

1. A List Of Low Friction Plastics You Should Know

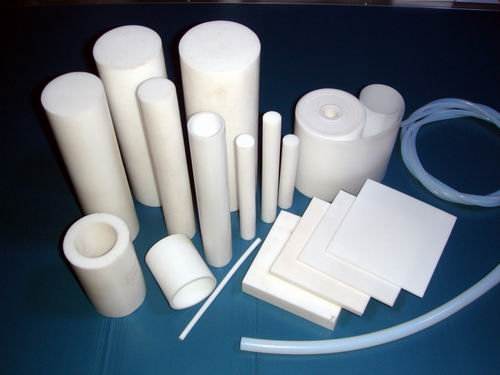

Low friction plastics are vital materials in numerous applications, primarily due to their unique ability to reduce friction and wear. This characteristic not only enhances the efficiency of mechanical components but also extends the lifespan of the products. Below are some noteworthy low friction plastics, each with distinct properties and applications:

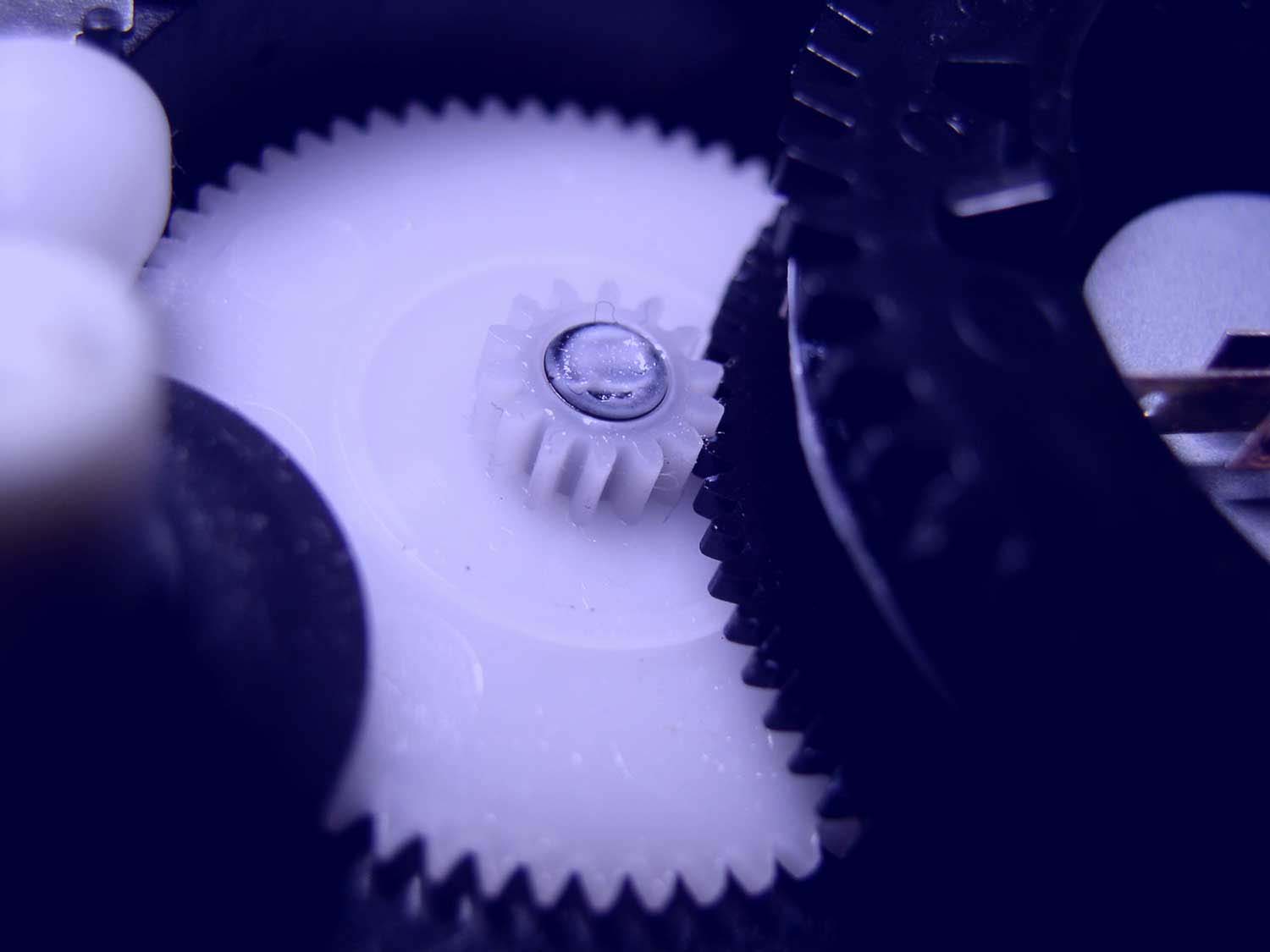

1.1. Polyoxymethylene (POM)

Polyoxymethylene, often referred to as acetal or polyacetal, is a high-performance engineering plastic that has gained prominence in various industrial applications. Known for its low friction properties and exceptional wear resistance, POM is characterized by its high strength and rigidity.

Polyoxymethylene is often referred to as acetal or polyacetal.

Overview: POM exhibits low moisture absorption, making it an ideal choice for precision components that require dimensional stability. Its excellent mechanical properties allow it to maintain performance even under high loads, making it suitable for demanding environments.

Applications: Commonly used in the production of gears, bearings, and automotive components, POM is favored in applications where high strength and rigidity are necessary. Industries such as automotive, aerospace, and consumer goods utilize POM for its reliability and longevity. For instance, POM gears in machinery help minimize wear, ensuring smooth operation over extended periods.

1.2. Polyethylene (PE)

Polyethylene is one of the most widely used plastics globally, and its low coefficient of friction makes it an excellent choice for applications requiring smooth movement and reduced friction. PE can be produced in various forms, including low-density polyethylene (LDPE) and high-density polyethylene (HDPE), each offering unique advantages.

Polyethylene is one of the most widely used plastics globally.

Overview: The flexibility and chemical resistance of polyethylene contribute to its versatility. It can withstand various environmental conditions, making it suitable for both indoor and outdoor applications.

Applications: PE is commonly found in packaging films, containers, and even in the manufacturing of low-friction surfaces for equipment and machinery. In the food industry, PE is often used in packaging to ensure that products remain fresh while minimizing friction during processing.

1.3. Polytetrafluoroethylene (PTFE)

Polytetrafluoroethylene, known by the brand name Teflon, is perhaps one of the most recognized low friction plastics due to its extremely low friction and non-stick properties. PTFE is a fluoropolymer that can withstand high temperatures and is resistant to most chemicals, making it highly versatile.

PTFE is commonly used in seals, bearings, gaskets, and non-stick applications.

Overview: PTFE’s unique molecular structure gives it remarkable properties, including excellent thermal stability and chemical resistance. It can operate effectively in extreme conditions, which makes it an ideal choice for various applications.

Applications: PTFE is widely used in cookware coatings, gaskets, seals, and in industries requiring low friction and high chemical resistance. In aerospace applications, PTFE is often used in fuel lines and valves due to its reliability and ability to prevent leaks.

1.4. Nylon (Polyamide)

Nylon, also known as polyamide, is a synthetic polymer that exhibits excellent toughness and low friction properties. It can be blended with other materials to enhance its characteristics, making it a popular choice in various applications.

Nylon is a synthetic polymer that exhibits excellent toughness and low friction properties.

Overview: Nylon’s ability to absorb moisture can affect its dimensional stability, but its overall strength and wear resistance make it a preferred material in numerous industrial applications. The modification of nylon with various additives can enhance its performance and durability.

Applications: Used in applications such as bearings, bushings, and automotive parts, nylon is appreciated for its durability and wear resistance. In the textile industry, nylon is used for its strength and elasticity, making it suitable for clothing and outdoor gear.

1.5. Polypropylene (PP)

Polypropylene is a versatile plastic with a low coefficient of friction. It is lightweight and has good chemical resistance, making it suitable for a wide range of applications across different industries.

Polypropylene is often used for bottle caps thanks to its lightweight properties.

Overview: PP can be easily molded and processed, making it a favorite among manufacturers. Its low density contributes to its lightweight nature, while its resistance to moisture and chemicals enhances its usability in various environments.

Applications: Commonly used in packaging, automotive components, and textiles, PP is a popular choice in various industries. For example, in the automotive sector, PP is often used for interior components due to its lightweight and durable characteristics.

1.6. Ultra-High Molecular Weight Polyethylene (UHMWPE)

Ultra-high molecular weight polyethylene (UHMWPE) is a subset of polyethylene that possesses an extremely high molecular weight, leading to enhanced strength and durability. Its low friction properties make it an exceptional choice for applications where reduced wear is critical.

UHMWPE is a subset of polyethylene that possesses an extremely high molecular weight.

Overview: UHMWPE has outstanding impact resistance and is often used in environments where heavy loads are a concern. Its ability to withstand harsh conditions makes it a preferred material for many industrial applications.

Applications: Common applications include conveyor systems, marine environments, and medical devices. In the medical field, UHMWPE is used in joint replacements due to its low wear rates and biocompatibility.

1.7. Polyvinylidene Fluoride (PVDF)

Polyvinylidene fluoride (PVDF) is a high-performance thermoplastic known for its excellent chemical resistance and low friction properties. Its stability in harsh environments makes it suitable for various applications.

PVDF is a high-performance thermoplastic.

Overview: PVDF is highly resistant to UV radiation, making it an ideal choice for outdoor applications. Its low friction characteristics contribute to its effectiveness in moving parts.

Applications: Commonly used in the chemical processing industry, PVDF is found in valves, fittings, and piping systems. Its ability to withstand aggressive chemicals while providing low friction makes it a reliable choice for many industrial applications.

2. Are Low Friction Plastics Bringing Benefits Or Setbacks?

While low friction plastics offer numerous advantages, it is essential to consider both the benefits and potential setbacks associated with their use. Understanding these aspects helps industries make informed decisions regarding the selection of materials.

2.1. Benefits of Low Friction Plastics

Reduced Wear and Tear: One of the most significant advantages of low friction plastics is their ability to significantly reduce wear on moving parts. This leads to an extended service life and less frequent replacements. For businesses, this can result in substantial cost savings over time, as fewer replacements mean lower maintenance costs.

Improved Efficiency: By minimizing friction, these plastics enhance the efficiency of machinery and equipment. This improved performance can lead to higher productivity and better energy efficiency. Industries that utilize low friction plastics in their machinery often see a noticeable increase in operational efficiency, allowing them to produce more with less energy.

Versatility: Low friction plastics can be used in a wide range of applications, from consumer products to heavy industrial machinery. Their adaptability makes them suitable for diverse industries. This versatility means that manufacturers can rely on a single material for multiple applications, simplifying their supply chain and reducing inventory costs.

Weight Reduction: Many low friction plastics are lightweight, which can contribute to overall weight reduction in products, particularly in the automotive and aerospace industries. This reduction not only improves fuel efficiency but also enhances performance, making these plastics particularly valuable in sectors where weight is critical.

Noise Reduction: Low friction plastics can also help reduce noise in mechanical systems. The smooth surfaces and low friction characteristics of these materials contribute to quieter operations, which is increasingly important in residential and urban environments.

Low friction plastics can also help reduce noise in mechanical systems.

2.2. Setbacks of Low Friction Plastics

Environmental Concerns: Many low friction plastics are derived from fossil fuels, raising concerns about their environmental impact. The disposal of plastic products can lead to pollution and other ecological issues. With increasing scrutiny on plastic waste, industries are pressured to seek more sustainable alternatives.

Cost Implications: While low friction plastics can reduce wear and maintenance costs, the initial cost of these specialized materials can be higher than traditional plastics. Companies must weigh the long-term savings against upfront expenses. It’s essential for businesses to consider their specific needs and budget constraints when selecting materials.

Limited Thermal Stability: Some low friction plastics may have limited thermal stability, making them unsuitable for high-temperature applications. This limitation could restrict their use in specific environments, particularly in industrial settings where heat generation is common.

Potential for Frictional Ignition: In some cases, low friction plastics can lead to increased static electricity buildup, which may pose a risk of ignition in flammable environments. Industries must implement appropriate safety measures when using these materials in potentially hazardous situations.

Processing Challenges: While low friction plastics have many benefits, they may also present challenges during processing. For example, certain low friction materials may require specific machinery or processing conditions, which can increase production complexity and costs.

3. Conclusion

In conclusion, low friction plastics play a crucial role in enhancing the performance and efficiency of various products and systems. Their unique properties, such as reduced wear and tear, improved efficiency, and versatility, make them indispensable in many industries. However, it is vital to consider the environmental implications and potential drawbacks associated with their use. As the demand for sustainable solutions grows, the development of bio-based low friction plastics could offer a viable path forward.

Manufacturers and industries should stay informed about the latest advancements in low friction plastics, including sustainable alternatives, to ensure they are making responsible and effective choices. The future of low friction plastics may include innovations that enhance their properties while also addressing environmental concerns, paving the way for a more sustainable approach to manufacturing.

4. About EuroPlas

At EuroPlas, we specialize in providing cutting-edge plastic solutions that cater to a broad range of industries, with a commitment to sustainability and performance. In the realm of low friction plastics, we offer a comprehensive lineup of products designed to meet the evolving needs of modern manufacturing. Here’s a look at our key products related to this area:

4.1. Engineering Plastics

EuroPlas offers high-performance engineering plastic compounds tailored for applications requiring low friction and superior wear resistance. These compounds, such as Polyamide (Nylon), are used in manufacturing gears, bearings, automotive components, and other precision products. These materials deliver exceptional mechanical strength, stability, and low friction qualities, making them ideal for demanding industrial applications.

4.2. Color Masterbatch

Our color masterbatches provide excellent aesthetic enhancements for low friction plastic applications. Available in a wide spectrum of colors, they offer stable pigment dispersion, heat resistance, and improved surface quality. By incorporating our color masterbatches, manufacturers can achieve both aesthetic appeal and functional durability in their final products, such as automotive parts or consumer goods, without compromising on quality.

4.3 Plastic Additives

To optimize low friction plastic performance, EuroPlas provides a variety of plastic additives. Our additive range includes anti-static additives, anti-UV additives, and processing aids, all designed to improve the functionality and longevity of plastic products. These additives help minimize friction, enhance chemical resistance, and protect against environmental factors, making them essential for industries where plastic durability is paramount.

4.4. Filler Masterbatch

Our filler masterbatch solutions, formulated with high-quality calcium carbonate (CaCO3), help manufacturers reduce costs while enhancing product properties such as hardness, durability, and printability. These filler masterbatches are especially beneficial for applications that require better processing stability, energy savings, and surface finish quality. This versatile solution can be applied across industries, from packaging to household goods.

4.5. Biofiller

EuroPlas offers biofillers as a sustainable and cost-effective alternative for eco-friendly plastic production. Our BiOMates biofillers, made from bioplastic and modified CaCO3, are designed to enhance gloss, film hardness, and surface quality while supporting biodegradability. BiOMates fillers are widely used in biodegradable packaging and other environmentally conscious products, helping manufacturers align with sustainability goals without sacrificing performance.

4.6. Bioplastic Compounds

Sustainability is a cornerstone of EuroPlas, and our bioplastic compounds are designed to reduce environmental impact without compromising on material properties. BiONext bioplastic compounds are derived from renewable resources such as polylactic acid (PLA) and Polyhydroxyalkanoate (PHA), as well as plant-based materials like corn and potatoes. These compounds allow for the production of biodegradable end products that can decompose within 12 months.

Bioplastic compounds are highly advantageous due to their biodegradable nature, making them ideal for environmentally friendly applications. Our bioplastics retain excellent mechanical properties, offering high hardness, impact strength, and elongation. They are widely used in applications such as food packaging, agricultural films, disposable items, and shopping bags, contributing to a circular economy.

If you’re looking to integrate low friction plastics into your projects, EuroPlas is here to help. Contact us today for more information about our products and how they can benefit your operations. Don't forget to check out our blog for more insights and updates!