As environmental concerns escalate and the global demand for sustainable alternatives grows, bio-based plastics have emerged as a key player in the push for greener materials. These plastics serve a dual purpose: maintaining the functionality of traditional plastics while contributing to the larger goal of sustainability. In this article, we will explore what defines bio-based plastics, their composition, advantages, and applications of bio-based plastics, with a focus on EuroPlas’ contributions to this evolving sector.

1. Definition Of Bio-Based Plastics

Bio-based plastics for containers

Bio-based plastics are a category of materials created, either partially or entirely, from renewable organic resources rather than petroleum. These organic resources include a wide range of plant-based materials such as corn starch, sugarcane, vegetable oils, and cellulose. What sets bio-based plastics apart is their origin—biological matter—compared to conventional plastics made from petrochemicals, which rely on non-renewable fossil resources. This distinction is crucial in assessing their potential for reducing the overall carbon footprint of products and industries.

2. What Can Be Called As Bio-Based Plastics?

When we refer to plastics as "bio-based," we are specifically talking about their feedstock, or the raw material from which they are made. This means that part or all of the plastic is derived from biological (living) resources. However, bio-based does not necessarily mean biodegradable. The term "bio-based" focuses on the origin of the material, while "biodegradability" refers to how the material behaves at the end of its life.

There are several types of plastics that can be considered bio-based, depending on their composition and source of raw materials:

Partially Bio-Based Plastics: Some plastics are only partially bio-based, meaning they incorporate a mix of both renewable resources and petrochemical components. A common example is Bio-PET (polyethylene terephthalate), which is made from plant-based materials like sugarcane but retains properties similar to conventional PET. This type of plastic is not biodegradable but is still considered bio-based because it utilizes renewable sources in its production.

Fully Bio-Based Plastics: These plastics are entirely derived from biological feedstocks and do not contain any fossil fuel-derived components. An example is PLA (polylactic acid), made from fermented plant sugars such as corn starch. PLA is both bio-based and biodegradable, making it a popular choice for packaging and single-use items. Another example is PHA (polyhydroxyalkanoates), which is produced by bacterial fermentation and is both bio-based and biodegradable.

Non-Biodegradable Bio-Based Plastics: It’s important to note that not all bio-based plastics are biodegradable. For instance, Bio-PE (bio-based polyethylene), which is produced from sugarcane, is chemically identical to conventional polyethylene and offers the same durability and non-biodegradable properties. These plastics can still be recycled through traditional systems, making them a sustainable alternative for industries looking to reduce their reliance on fossil fuels.

Biodegradable Bio-Based Plastics: Plastics like PLA and PHA can break down into harmless byproducts in the right conditions, such as industrial composting facilities. These are widely used in applications like food packaging, disposable cutlery, and agricultural films.

3. Advantages of Bio-Based Plastics

Bio-based plastics offer several key advantages over traditional petroleum-based plastics, which makes them a compelling choice for industries looking to adopt more sustainable practices. Below are the primary benefits of using bio-based plastics:

3.1. Reduced Carbon Footprint

One of the most significant advantages of bio-based plastics is their ability to reduce carbon emissions. Since they are made from renewable plant-based resources, they absorb CO2 from the atmosphere during the growth phase of these plants. This process helps offset the carbon emissions generated during production. By contrast, traditional plastics made from fossil fuels release large amounts of carbon dioxide during their lifecycle, from extraction to disposal, contributing to the growing problem of greenhouse gas emissions.

3.2. Renewable Resource Base

Bio-based plastics can reduce carbon emissions

Bio-based plastics are derived from renewable resources such as corn, sugarcane, and other plants, unlike petroleum-based plastics that rely on finite fossil fuels. These renewable feedstocks can be replenished annually, providing a more sustainable source of raw materials. This shift away from non-renewable resources can help reduce dependence on oil, which is becoming increasingly scarce and expensive. Additionally, plant-based plastics can support agricultural economies by creating demand for biomass production.

3.3. Energy Efficiency in Production

The production of bio-based plastics often requires less energy than traditional plastics, especially when using feedstocks like corn or sugarcane. This lower energy demand further contributes to their reduced environmental impact. Moreover, technological advancements have made the conversion of biological materials into plastic polymers more efficient, meaning less energy is required to produce the same volume of bio-based plastics.

3.4. Versatility and Performance

Many bio-based plastics exhibit performance characteristics similar to, or even superior to, conventional plastics. For example, bio-based polyethylene (Bio-PE) has the same strength and durability as petroleum-based polyethylene, making it a suitable replacement in industries like packaging and consumer goods. Similarly, bio-based polylactic acid (PLA) is not only biodegradable but also exhibits high tensile strength and clarity, making it ideal for applications in packaging, 3D printing, and disposable products.

3.5. Compatibility with Existing Recycling Systems

Bio-based plastics are compatible with recycling systems

Another important advantage of some bio-based plastics is their compatibility with existing recycling infrastructures. Plastics like Bio-PE and Bio-PET can be recycled alongside their traditional counterparts, making it easier for manufacturers and consumers to adopt them without needing significant changes in waste management practices. This makes bio-based plastics a more accessible and scalable solution to the plastic pollution problem, as they can be seamlessly integrated into the current system.

3.6. Biodegradability in Some Forms

While not all bio-based plastics are biodegradable, certain types like PLA and PHA can break down into harmless byproducts in specific conditions, such as industrial composting facilities. This property is especially advantageous in reducing plastic waste in applications like single-use packaging and disposable items. When properly disposed of, biodegradable bio-based plastics can contribute to a circular economy by transforming waste into resources like compost, which can be used in agriculture.

3.7. Reduced Environmental Impact

By using plant-based raw materials and producing fewer greenhouse gas emissions, bio-based plastics contribute to a lower overall environmental impact. They not only help decrease pollution and resource depletion but also offer potential improvements in waste management. As more companies and governments commit to reducing plastic waste and carbon emissions, bio-based plastics offer a tangible solution that aligns with global sustainability goals.

4. Applications of Bio-Based Plastics

Bio-based plastics are finding widespread use across numerous industries, thanks to their versatility and sustainability. Here are some of the key applications:

4.1. Packaging Industry

Bio-based plastics in the packaging industry

One of the largest and fastest-growing markets for bio-based plastics is the packaging industry. Bio-based plastics such as PLA, Bio-PE, and Bio-PET are increasingly being used to produce containers, films, and bottles for food, beverages, and personal care products. These materials provide the necessary durability to preserve product freshness while offering a reduced carbon footprint compared to petroleum-based alternatives. The biodegradability of some bio-based plastics, like PLA, also makes them an attractive option for single-use packaging, as they can break down in industrial composting systems.

In addition, bio-based plastics used in packaging can enhance brand perception by aligning with consumer preferences for eco-friendly products. Many companies are turning to bio-based solutions as part of their commitment to reducing plastic waste and enhancing sustainability throughout the supply chain.

4.2. Automotive Industry

Bio-based plastics are finding increased applications in the automotive industry due to their lightweight and durable properties. Materials like Bio-PA (Bio-Polyamide) are used in car interiors, engine components, and exterior parts, offering the same strength and heat resistance as their petroleum-based counterparts. By using bio-based plastics, automotive manufacturers can reduce the overall weight of vehicles, which improves fuel efficiency and lowers carbon emissions.

Moreover, bio-based plastics in the automotive sector can be designed to meet high-performance standards, including resistance to chemicals, heat, and mechanical stress. These properties make them an ideal material for producing parts that need to withstand tough conditions over a long period, such as in engine compartments and vehicle exteriors.

Bio based plastics applied in car interior

4.3. Consumer Goods

The consumer goods industry, including electronics, household items, and toys, is also embracing bio-based plastics. For example, bio-based polyethylene is used in the production of electronics casings and household products like containers, kitchenware, and toys. The demand for sustainable materials in this sector is growing rapidly, as consumers increasingly prioritize eco-friendly products that reduce environmental impact.

Bio-based plastics offer the same durability, flexibility, and functionality as traditional plastics, making them a viable alternative without compromising product performance. This shift helps reduce the use of petroleum-based plastics in daily consumer items, contributing to the broader goal of reducing plastic waste.

4.4. Textiles and Apparel

The textiles industry has also embraced bio-based plastics, with materials like PTT (polytrimethylene terephthalate) used to create fabrics for clothing, upholstery, and carpets. Bio-based textiles offer the same softness, elasticity, and durability as traditional polyester but with a reduced environmental footprint. These materials can be sourced from renewable resources such as corn or sugarcane, further supporting the movement towards sustainable fashion.

Bio-based plastics in textiles also contribute to circularity in fashion, as some bio-based fabrics are recyclable, reducing waste in an industry known for its significant environmental impact. As the fashion industry increasingly moves toward eco-conscious practices, bio-based plastics offer a promising solution for creating high-performance textiles with a lower environmental toll.

4.5. Agriculture

In the agricultural sector, bio-based plastics are used to produce mulch films, irrigation systems, and packaging for agricultural products. These plastics help improve efficiency in farming operations while offering a more sustainable alternative to traditional plastic products. For example, bio-based mulch films made from PLA can be composted after use, contributing to soil health and reducing the need for conventional plastic disposal.

Bio-based plastics are also employed in the production of biocompatible seed trays and other agricultural tools, offering the same durability as traditional materials while providing the added benefit of sustainability. With the agricultural industry increasingly focused on reducing plastic waste and improving resource management, bio-based plastics offer practical solutions to these challenges.

Bio based plastics applied in agriculture

5. About EuroPlas’ Bioplastics

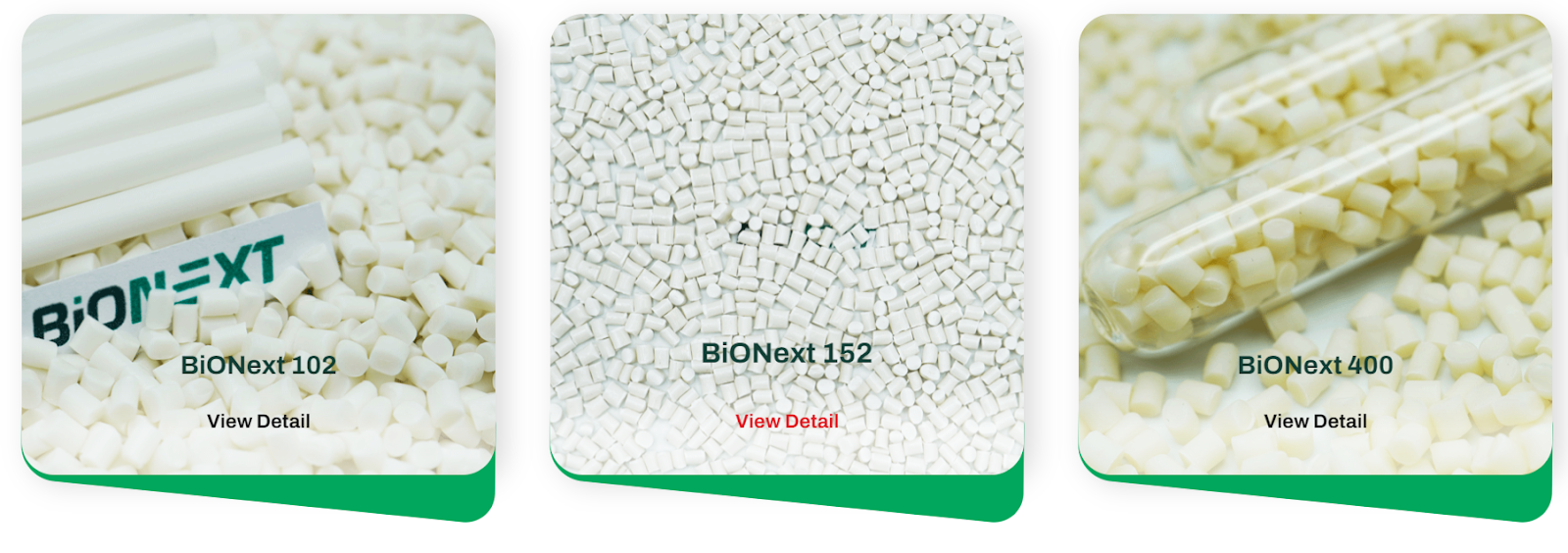

EuroPlas is at the forefront of developing sustainable solutions with its innovative BiONext bioplastic compounds. These bio-based materials are created from renewable resources such as polylactic acid (PLA) and polyhydroxyalkanoate (PHA), offering a biodegradable solution that decomposes within 12 months. BiONext products not only contribute to environmental sustainability but also provide excellent mechanical properties, including high strength and durability, making them suitable for injection molding, extrusion, and blown film applications.

Bio based plastics - BiONext at EuroPlas

EuroPlas continues to drive innovation in the bioplastics market, positioning BiONext as a key material for reducing the plastic industry’s reliance on fossil fuels while delivering products that meet the functional demands of modern industries. From packaging and consumer goods to agriculture, EuroPlas is playing a crucial role in shaping a sustainable future with bio-based solutions.

For more information about EuroPlas’ Bioplastics, please don’t hesitate to reach out. Contact us today!