Plastics are one of the most commonly used materials in many industries. Manufacturers always require an effective plastic cutting tool to get their job done with high accuracy and zero damage.

Since there are various plastic cutting tools in the market to work with different types of plastics, choosing the right option seems complicated. This article will help you find out with tips to simplify the process. Let's follow along!

Read more: What is plastic? Everything you need to know about plastic

1. Things to know before cutting plastics

The thing is that friction is needed for cutting, but it produces heat at the same time, causing the plastics to melt when heated.

If your material gets melted a little bit, you'll have uneven and rough edges. If it melts too much, you'll face the process called "chip-weld," in which the material will re-bond behind the cutting tool. In both cases, your final products will not meet the quality and aesthetic requirements.

Using high spindle speeds and low feed rates is a good general rule of thumb when working with plastic to reduce the heat. You should modify feeds and speeds based on the chip formation. Ideally, the chips should be relatively small.

Long, stringy chips can appear on plastics, requiring regular chip cleaning to avoid entanglement and interfering with the cutting process.

Over-clamping can lead to breakage and deformation since plastics are softer and more flexible than metals. Thus, it's better to use soft jaws or fixtures to avoid scratching the surface.

Keeping the incision shallow might also aid in avoiding heat accumulation. It is cooler to have two shallow passes than one deep pass.

Many polymers can be machined dry. However, with a coolant or air blast, you can avoid melting some plastics and enhance their surface quality. Make sure the coolants you use are appropriate for the plastic. Certain polymers may absorb the coolant, which might cause deterioration or changes in dimensionality.

If our final products require a smooth surface, using a finishing pass with a fine tool and a slower feed rate is highly recommended.

When some polymers are machined, harmful gases may be released. Always make sure there is enough ventilation, and use safety gear, such as masks and goggles.

2. Tips to choose the plastic cutting tool

For machining purposes, plastic material can be broadly divided into two categories: soft and hard. Single or double-edge "O" flute tools, which come in straight or spiral shapes, are needed for soft plastic material. Hard plastic calls for spiral "O" flutes with hard plastic geometry and double-edge "V" flute tools. It is advised to use three-edge finishers. For manual operations, high-speed steel and solid carbide are easily obtainable as tool materials for the majority of these router bits, which are CNC machinable.

The possibility of plastic chipping while cutting increases with its hardness. In case of chipping, try to have more teeth on each blade. Reduce the number of teeth, though, if the material begins to exhibit indications of glazing or overheating. Soft plastics, as previously said, require fewer teeth.

Thinner plastics are easier to chip than harder ones. As a result, the rake angle should be lowered, and the blade will need more teeth. Plus, the sharp top bevel angles may be necessary, especially when dealing with very soft or paper-thin polymers.

Fewer teeth, a greater radial clearance angle, and more tooth overhang are necessary for heat-sensitive polymers.

3. Tools to avoid

Before getting to know the best plastic cutting tools, you should know which one you should not use to avoid poor cuts and dangerous situations. They include:

- Traditional sharp utility knife: Traditional utility knives have extremely sharp edges that pose a significant risk to safety even though they may be useful for cutting things.

- Kitchen knife: Plastics are not intended to be cut with kitchen knives. It might be risky and inefficient to use one.

- A hot knife: Cutting through plastic with a hot knife will put you in danger of plastic ignition and burning.

- Power tools: These tools pose the risk of getting a burn since the RPM (revs per minute) power tools will melt the plastic you are cutting through.

4. List of most commonly used plastic cutting tools

4.1. Hard plastics

4.1. Hard plastics

Hard plastics include both thin and thick types, but the term "hard" refers to the plastic's brittleness. Plastic toys and pegs are two examples of hard plastic.

Using the incorrect tools for cutting brittle, hard plastic might cause the edge to break or fracture. The best hard plastic cutting tools are a saw or a piece of string, depending on the size, direction, and precision of the cut.

A saw: A jigsaw, hand saw, and table saw are perfect for cutting thick, hard plastics. It's highly recommended to choose a blade with a high tooth count for a smoother cut.

A piece of string: It's an ideal option for cutting small pieces of hard plastic, including hand-made plastic toys or other hard plastic craft goods.

4.2. Thick plastics

With plastics that are thicker than ¼ inches (such as plastic skirting, plastic piping, and Perspex sheeting), the best equipment is a saw.

For precise and smoothest plastic cutting, a fine-toothed saw works most effectively. It also serves you well when you need to make several non-linear cuts.

If you want to cut thicker plastic items, like pipes, a jigsaw works great. However, it might not provide you with precise results.

Larger plastic pipes or thick plastic blocks are easily cut using a table saw. Remember to use a non-melting blade with caution.

4.3. Thin plastics

Plastic sheets, plastic packing, and plastic banding are a few examples of thin plastic. In this case, the most suitable plastic cutting tool is a utility knife, as it offers excellent control and grip. A utility knife functions similarly to scoring glass. Since the tool cuts a shallow incision in the plastic, making it easier to break the plastic or cut through it completely.

5. EuroPlas - Where you can find the best plastic materials

EuroPlas is known as a leader in the masterbatch field since the company satisfies a wide range of requirements for unique plastic raw material solutions to optimize production costs and improve the competitiveness of the customers.

Here is the list of outstanding products from EuroPlas:

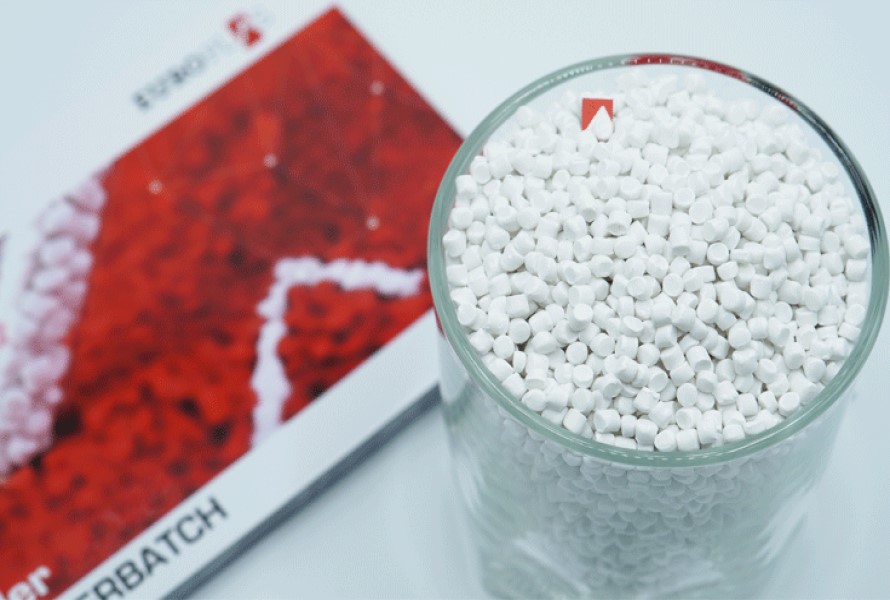

With more than 15 years of producing and exporting filler masterbatch to thousands of businesses around the world, EuroPlas is proud to offer a wide range of filler masterbatch to help manufacturers save cost, enhance productivity and produce high-quality plastic products.

EuroPlas filler masterbatch combines calcium carbonate CaCO3, primary resin, and other plastic additives based on the customers' requirements. The products have many advantages, such as reduced shrinkage, improved stiffness, and bend strength, the capability to enhance stability, printability, and surface quality of the final products, and energy savings. It's ideal for injection molding, blow molding, PVC pipe manufacturing, packaging, plastic frames, door production, etc.

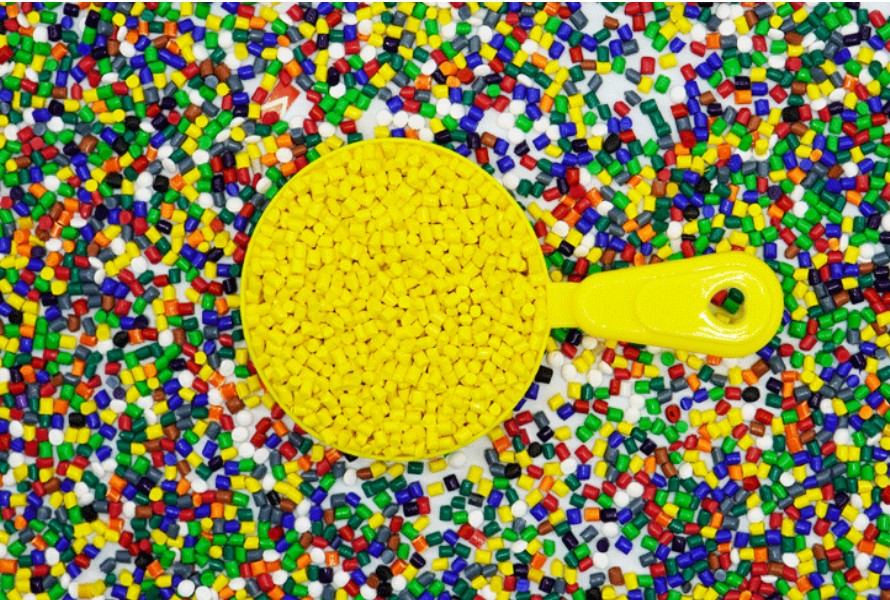

Color masterbatch from EuroPlas is a solution for end-product aesthetics. It's made from high-quality pigments, carrier resin, and some special additives, creating a colorful and attractive appearance. EuroPlas provides a wide range of colors and effects, from simple to complicated, of color masterbatch.

Color masterbatch from EuroPlas is a solution for end-product aesthetics. It's made from high-quality pigments, carrier resin, and some special additives, creating a colorful and attractive appearance. EuroPlas provides a wide range of colors and effects, from simple to complicated, of color masterbatch.

Besides the help to meet color requirements, the material saves time and cost as manufacturers can use it directly in the production process. Plus, it causes no harm to the environment.

Plastic additives are a necessary substance used in the production process to improve the material's performance. Besides, they help the plastic become more durable, thanks to the enhanced chemical and physical resistance.

Plastic additives are a necessary substance used in the production process to improve the material's performance. Besides, they help the plastic become more durable, thanks to the enhanced chemical and physical resistance.

EuroPlas has a wide range of additives for plastic, such as Flame retardants, Desiccants, Odor removing additives, Anti-UV additives, Anti-aging additives, Anti-fog additives, Antistatic additives, Anti-blocking additives, and Processing-aid additives.

EuroPlas engineering plastic compound is full-function-in-one-material to save time and production costs. The combination is made of resin, additives, and reinforcements (based on the end-product requirements).

EuroPlas engineering plastic compound is full-function-in-one-material to save time and production costs. The combination is made of resin, additives, and reinforcements (based on the end-product requirements).

All EuroPlas products are various, including PA6, PA66 blend compound, PBT GF-FR compound, ABS Glass fiber compound, ABS Antistatic compound, PC flame retardant compound, and ABS. All are of high quality and flexibility. If you're looking for a material for automobile, electronics manufacturing, interior decoration, and renewable energy, you should not miss these products from EuroPlas.

As a professional, EuroPlas understands the industry's ongoing trend and demand for green, biodegradable plastic. And the company is also concerned about sustainable development and the environment; thus, a list of high-quality EuroPlas bioplastic compounds is produced to be used in various aspects, including automotive & transport, construction, fibers, electronics, household appliances, and especially food packaging.

As a professional, EuroPlas understands the industry's ongoing trend and demand for green, biodegradable plastic. And the company is also concerned about sustainable development and the environment; thus, a list of high-quality EuroPlas bioplastic compounds is produced to be used in various aspects, including automotive & transport, construction, fibers, electronics, household appliances, and especially food packaging.

BioNEXT, a bio compound exclusively developed by EuroPlas, can be decomposable within 12 months after use. The company guarantees that the end product passes strict quality control management to meet all the requirements.

Contact EuroPlas right now for the best price of all products!