Plastic outdoor furniture has become increasingly popular due to high applicability, low maintenance, and affordability. However, regular exposure to the elements, such as sunlight, rain, and dust, can cause the plastic to deteriorate over time, affecting its appearance and functionality. To combat these issues, manufacturers added polymer additives for plastic outdoor furniture. These additives enhance the properties of the plastic, making it resistant to various environmental factors and improving its overall performance. This article will explore the different types of polymer additives used in the manufacture of plastic outdoor furniture and the benefits they provide.

Related:

- What are plastic additives? 8 most common plastic additives in plastic industry

- Top 5 polymer additives for agricultural films

- Automotive UV stabilizers - All you should know

- Clarifying agent for plastic - everything you need to know

- Antistatic additive for plastics - all you should know

- Top 20 reliable plastic additives companies in 2022

1. Why need polymer additives for plastic outdoor furniture?

The use of polymer additives in the production of plastic outdoor furniture has become increasingly popular in recent years, as manufacturers look for ways to create high-quality, long-lasting products that are both functional and attractive. Polymer additives are substances added to the raw plastic material during the manufacturing process, with the goal of improving the properties of the final product. These additives can enhance the material's durability, weather resistance, color stability, and much more, making plastic outdoor furniture better suited to its intended use. Some of the key benefits of polymer additives include:

Improved weather resistance

One of the main benefits of polymer additives in the production of plastic outdoor furniture is improved weather resistance. Polymer additives such as ultraviolet (UV) stabilizers and anti-oxidants are added to protect the material from the harmful effects of UV radiation and prevent the material from breaking down due to exposure to the elements. This ensures that the furniture remains functional and attractive for many years, even when exposed to the elements.

Enhanced durability

Another key benefit of polymer additives is enhanced durability. Additives like impact modifiers and reinforcing agents are added to increase the toughness of the material, making it less susceptible to cracks, chips, and other forms of damage. This improves the overall quality and longevity of the furniture, reducing the need for frequent repairs or replacements.

Increased color stability

Polymer additives can also be used to enhance the color stability of the material. Colorants and pigment masterbatches can be added to create vibrant, eye-catching colors and patterns that remain stable over time, even when exposed to the elements. Because it can help to keep the material looking attractive and vibrant for many years, even in harsh outdoor environments, kinds of polymer additives are increasingly preferred for plastic outdoor furniture.

Anti-fogging properties

Anti-fogging agents can be added to prevent condensation from forming on the surface of the material, improving visibility and reducing the risk of mold or mildew growth. This is particularly important for plastic outdoor furniture, as condensation can cause unsightly streaks and discoloration, and can also provide an ideal environment for mold and mildew growth.

Improved processing

Some polymer additives can also make the production process more efficient and cost-effective, allowing manufacturers to produce high-quality products with lower costs and faster production times.

Enhanced sustainability

By using biodegradable additives, manufacturers can create environmentally friendly products and can be easily broken down into natural, harmless substances.

Generally speaking, the use of polymer additives in the production of plastic outdoor furniture provides numerous benefits, making the final product more durable, attractive, and functional. In addition to these benefits, some polymer additives can also make the production process more efficient and cost-effective. This allows manufacturers to produce high-quality products with lower costs and faster production times, making it easier to meet the demands of consumers for the production of high-quality outdoor furniture.

2. Common polymer additives for plastic outdoor furniture

2.1. Color additive masterbatch

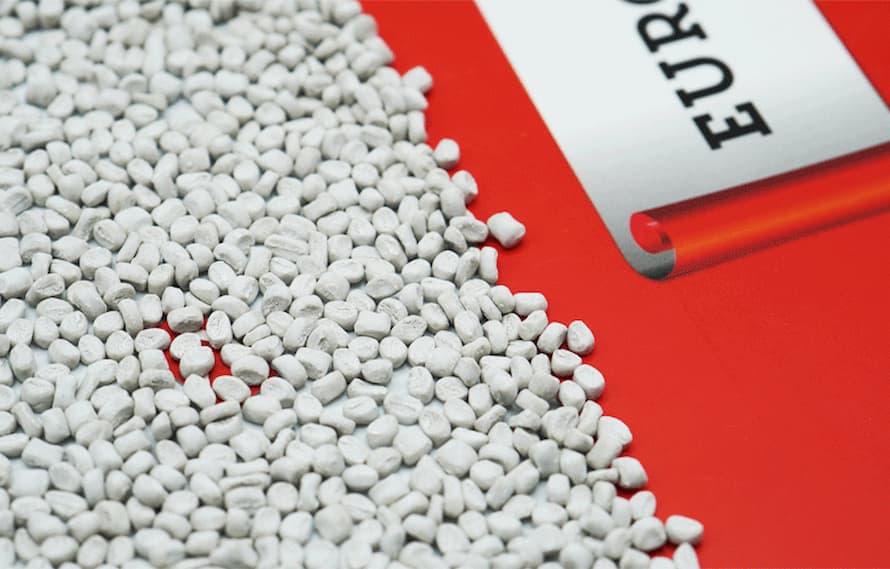

Color additive masterbatch is a specialized additive used to color plastic products, including plastic outdoor furniture. The additive is made by blending pigments and resin to form small pellets. These pellets are then mixed with the plastic resin used to make the furniture, resulting in a color that is evenly distributed throughout the product. Using color additive masterbatch for plastic outdoor furniture offers several benefits, including:

One of the biggest benefits of using color additive masterbatch is that it provides consistent coloring throughout the product. This type of masterbatch ensures that the final product has an even and uniform color, without any streaks or variations. This is because the pigments are pre-mixed into the masterbatch, which ensures that the color is evenly distributed throughout the product.

By using a color additive masterbatch, manufacturers can save time and reduce costs as compared to manually adding pigments to the resin. This is because the masterbatch is pre-mixed, reducing the time required to manually add pigments to the resin. Furthermore, the use of a specialized compound can help manufacturers avoid the need to purchase and store large quantities of pigments, which can be costly and time-consuming.

Color additive masterbatch provides enhanced quality in terms of color consistency, saturation, and vibrancy. This type of masterbatch provides enhanced color consistency, saturation, and vibrancy, which can improve the overall appearance and appeal of the end product.

By using color additive masterbatch, manufacturers can produce plastic outdoor furniture that is both visually appealing and cost-effective, helping to meet the demands of the marketplace.

2.2. Anti UV additives

Anti-UV additives are essential components in producing plastic outdoor furniture, especially those exposed to harsh environmental conditions like sunlight and extreme temperatures. The sun's UV rays can cause significant damage to plastic material, resulting in discoloration, cracking, and degradation. These effects can reduce the furniture's durability and lifespan, leading to costly repairs and replacements.

Anti-UV additives are created in line with how much exposure to the outdoors, direct sunlight, and certain climate conditions the chosen product will receive. Specifically, the role of anti-UV additives is to protect the plastic from the damaging effects of UV light by absorbing and scattering the UV rays. They do this by adding a layer of protection to the plastic, which helps to reduce the amount of energy absorbed by the material. This prevents the plastic molecules from breaking down, which would otherwise cause the plastic to become brittle and lose its structural integrity.

Every plastic product has unique chemical properties and must react differently to various environments. An anti-UV additive, including additional additives that are mixed into the polymer during production, must be created in line with certain predefined criteria in order to be genuinely effective.

Different hues and tints have varying propensities for UV damage. The addition of anti-UV additives also helps to maintain the original color of the plastic outdoor furniture for a longer period of time. This is because UV light is one of the primary causes of fading and discoloration in plastic materials. By protecting the furniture from the damaging effects of UV rays, anti-UV additives help to keep the plastic-looking fresh and new for much longer.

The lifecycle of plastic goods varies. Some items are predicted to have shorter life cycles than others, and vice versa. In order to extend UV additives' service lives as needed, they are made to match exact service life expectations.

When compared to other methods of protecting plastic outdoor furniture, the cost of using anti-UV additives is relatively low. Additionally, the benefits of using anti-UV additives far outweigh the cost, as they help to extend the lifespan of the furniture, reduce the need for repairs and replacements, and maintain the furniture's appearance and market value.

Anti-UV additives are an important aspect of the production of plastic outdoor furniture. They provide a critical layer of protection against the damaging effects of UV light, helping to extend the furniture's lifespan, maintain its appearance, and improve its market value.

2.3. Anti aging additives

During use, plastic products are exposed to various environmental factors such as sunlight, moisture, high temperature, dirt, chemicals, etc. These will gradually create free radicals, resulting in the incorporation of oxygen into the framework structure, thereby reducing the molecular weight of the polymer.

Thus, the advent of anti-aging additives for plastic outdoor furniture are essential for ensuring the longevity of these products. These additives are added to the raw material during the manufacturing process and serve the purpose of preventing the plastic from deteriorating due to environmental factors such as UV rays, high temperatures, and extreme weather conditions.

The presence of anti-aging additives in plastic outdoor furniture offers numerous benefits to both manufacturers and consumers. Some of the significant benefits include:

- Improved resistance to weathering

Anti-aging additives help to prevent the loss of mechanical and physical properties of plastic as a result of exposure to various weather conditions, such as UV radiation and temperature changes. Therefore, during use, outdoor applications (such as tarpaulins, stadium seats, garden products, power transmission lines, outdoor junction boxes, etc.) require the use of materials. Anti-aging protects them from discoloration and mechanical degradation due to harmful elements.

- Extended product lifespan

During use, plastic outdoor furniture is easily affected by many external factors such as moisture, sunlight, oxygen, physical impacts, etc. This weakens the molecular bonds, leading to physical changes on the plastic surface including mechanical degradation, discoloration, etc. By adding anti-aging additives to the resin, such as HAS (Hindered amine stabilizer), the oxidation process will be obstructed, thus extending the life of the product.

- Enhanced appearance and safety

Anti-aging additives help to maintain the aesthetic appearance of plastic outdoor furniture by preventing yellowing, fading, and cracking. This helps to maintain the look of the furniture for longer periods, even in harsh outdoor conditions. Plastic outdoor furniture that has been treated with anti-aging additives is also less likely to break or become brittle over time, reducing the risk of injury or accidents.

The use of anti-aging additives in plastic outdoor furniture is a critical aspect of the manufacturing process for plastic outdoor furniture and ensures that the products last longer and maintain their performance and appearance. The benefits offered to both manufacturers and consumers make it a must-have ingredient in the production of high-quality plastic furniture.

2.4. Anti scratch additives

Anti-scratch additives are an important component in the production of plastic outdoor furniture. These additives are designed to improve the scratch resistance of the plastic surfaces and prolong the lifespan of the furniture. Anti-scratch additives have various forms available in the market, including a range of polymers (PET, PLA, Polycarbonate, and PMMA) and other materials that can be blended with the base polymer. The following are some of the key benefits of using anti-scratch additives for plastic outdoor furniture:

- Improved scratch resistance

The main purpose of anti-scratch additives is to increase the scratch resistance of plastic surfaces, making them more durable and long-lasting. This helps to reduce the impact of daily wear and tear, such as scratches and scuffs, on the furniture, which can cause significant damage over time.

The use of anti-scratch additives helps to prolong the lifespan of plastic outdoor furniture, which is a major benefit for manufacturers and consumers alike. The furniture remains in good condition for longer, which helps to reduce the need for replacements and repairs, and saves money in the long run.

- Improved visual appearance

Anti-scratch additives reduce the visibility of scratches and scuffs on the surface, resulting in an improved look and an increased lifetime of the part. This helps to keep the furniture looking new and attractive for longer, which is important for maintaining the value and appeal of the product.

Anti-scratch additives help to enhance the performance of plastic outdoor furniture by providing a more durable and long-lasting material that is resistant to scratches and scuffs. This makes the furniture more suitable for use in outdoor environments, where it is subjected to a variety of weather conditions and other stresses.

The use of anti-scratch additives in plastic outdoor furniture provides many important benefits that help to improve the performance, lifespan, and appearance of the product. These additives play an important role in the production of high-quality, long-lasting outdoor furniture that can stand up to the demands of the outdoor environment.

2.5. Desiccant additives

Desiccant additives are special ingredients added to the production process of plastic outdoor furniture to absorb moisture. This helps to prevent the buildup of moisture within the plastic, which can cause various problems such as warping, cracking, and discoloration. The main benefit of using desiccant additives is that they extend the lifespan of the furniture and help maintain its aesthetic appearance. Here are some benefits of using desiccant additives for plastic outdoor furniture:

Desiccant additives prevent the buildup of moisture within the plastic, which helps to prevent warping, cracking, and other forms of degradation.

Moisture buildup within plastic furniture can cause discoloration, which can make the furniture look unsightly. Desiccant additives help prevent this discoloration, ensuring that the furniture remains aesthetically pleasing.

- Improved resistance to stains and odors

Moisture buildup within plastic furniture can also lead to the buildup of bacteria and other microorganisms. Desiccant additives help to prevent this buildup, improving the resistance of the furniture to stains and unpleasant odors.

3. EuroPlas - A renowned manufacturer of polymer additives for plastic outdoor furniture

European Plastic Company (EuP) is the world’s largest filler masterbatch manufacturer located in Vietnam. Now, EuroPlas provides a wide range of high-quality additive products: Odor removing additive, Desiccant additive, Anti-fog additive, Anti-aging additive, and Anti-UV additive.

Having up to 20 years of experience in the plastic material market, EuroPlas takes pride in providing customers with the highest quality polymer additives for plastic outdoor furniture. Our goods have undergone testing to guarantee their high efficacy throughout both the production process and their service life. Up to now, Europlas's products are high-quality goods that have delighted up to +10,000 clients in +85 nations.

If you want to get more details about our plastic additives, please contact us via email/phone number. We are more than happy to help!