Clarifying agent for plastic is an effective additive that improves the transparency of plastic products. In the production process, businesses can use additives to increase transparency to help products achieve high aesthetics and improve quality. It can be said that the clarifying agent for plastic is a new direction for the plastic industry. Let's discover this additive in the article below!

.jpg)

1. Clarifying agent for plastic - Why do we need it?

1.1. What is clarifying agent for plastic?

Clarifying agents are substances that are added to a liquid in order to eliminate or decrease the concentration of one or more undesired components in order to improve the liquid's clarity, color, fragrance, and/or stability.

Related:

- What are plastic additives? 8 most common plastic additives in plastic industry

- Where to buy high-quality transparent filler masterbatch?

- BaSO4 transparent filler masterbatch and 4 applications in plastic industry

The clarifying agent for plastics is a material that is used in the manufacturing of plastics and items connected to the production of plastics. This substance helps to raise the clarity of PP by lowering the size of the spherulites in the plastic. The haze of the component was spoken for by the smaller spherulites, which allowed more light to pass through the polymer. Clarifiers, in contrast to nucleating agents, are transparent, which helps to minimize haze values and also makes them easier to see.

1.2. Why do we need clarifying agent for plastic?

Polypropylene offers a potential solution to the problems associated with increasing the environmental responsibility of plastic packaging. It uses less material and weights less overall because of its low density, which lowers the cost. It also has a little carbon effect since fewer pollutants are created during manufacture. Additionally, it doesn't have any unfavorable side effects during recycling, such as off-gassing or crosslinking and producing a gel.

Lack of transparency is the main drawback of utilizing PP as a packaging material. PP is less transparent than polyethylene terephthalate (PET) and polycarbonate (PC), or glass, and is a semicrystalline substance with a natural haze. Although issues still exist, technological advancements are enhancing polypropylene's look. However, some challenges still remain.

To address this issue, new additives known as clarifying agents for plastic have been developed to be added to random copolymers of PP. The mission of this additive is to produce the appropriate clarity, reduce haze, and facilitate clarifying agent dispersion. The clarifier has substantially greater solubility and has received permission for use in food contact from both the European Food Safety Authority (EFSA) and the US Food and Drug Administration (FDA).

It not only raises the bar for clarity but also gives processors the ability to significantly boost their economics by lowering processing temperatures and shortening cycle times. It improves clarity, imparts low haze, and maintains the ideal balance of impact stiffness.

1.3. Benefits of using clarifying agent for plastic

- Offers exceptional clarity, especially in high-melt-flow situations (MFI of more than 20), unpredictable copolymers and homo-polymers of polypropylene.

- When opposed to traditional clarifiers of the sorbitol type, these clarifiers may be processed at lower temperatures.

- Enhanced flow qualities in comparison to traditional products of the sorbitol type, allowing for improved handling and dosing.

- Ideally suited for use in processes involving injection molding.

1.4. Applications of clarifying agent for plastic

Clarifying agent for plastic is often applied in injection molding applications made of polypropylene, such as caps and closures, food storage containers, and housewares.

2. Where to buy clarifying agent for plastic?

Clarifying agent for plastic of the European Plastic Joint Stock Company (EuP) has been strongly trusted by numerous plastic bag manufacturers in Vietnam and around the world. The clarifying agent used in EuP's plastics products has undergone extensive study over the years to guarantee the finest quality while yet being reasonably priced and widely available to consumers.

Advantages of clarifying agent for plastics from EuroPlas:

- Optimizing manufacturing costs

- Reducing the size of the spherulites to significantly improve PP clarity (spherical semi-crystalline regions)

- Aiding in lowering haze levels.

- Enhancing hardness, lowering shrinkage, and other factors that help to improve certain surface characteristics of final products.

As the leading producer of filler masterbatch in the world, EuroPlas is pleased to provide a special plastic material solution that aids clients' factories in reducing production costs and boosting market competitiveness. EuP is dedicated to giving users the best possible experience. As a result, consumers can be entirely confident in the quality of the goods and services when they use our PP filler clarifying agent for plastic products.

If there is a need, please contact us via the form to get the earliest advice and support!

3. Besides clarifying agent for plastic, which method can we use to make our plastic product more transparent?

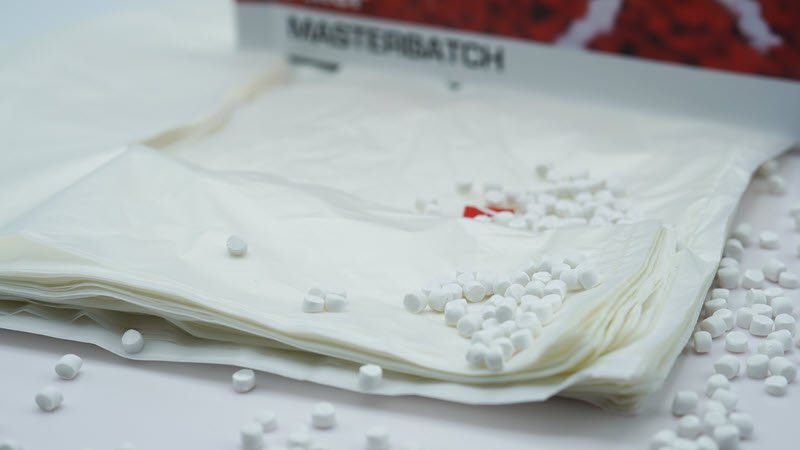

In addition to using transparency additives, transparent filler masterbatch can be used to increase the transparency of the finished product. Transparent filler masterbatch (also known as salt filler) is a combination of Na2SO4 (or BaSO4) salt, based on PP or PE plastic and other special additives. This is a product that has been around for a long time but has only been widely used in the last decade or so.

Plastic fillers have many benefits such as:

- Cost optimization

- Transparency, good dispersion, light fastness

- Increases physical durability, creates good gloss, good for color products

Save fuel thanks to the good thermal conductivity of CaCO3

If you are looking for a reliable transparent filler masterbatch, then EuP will be your first choice. Currently, many enterprises producing finished plastic products in more than 80 countries and territories have been importing this product. For more details and advice, do not hesitate to contact us!