In recent decades, filler masterbatch has been the go-to solution in plastic industries to reduce cost, speed up productivity, and enhance the mechanical properties of end products. In this blog, we’ll discover one of the most popular filler masterbatch - PP filler and its application in producing PP non-woven fabrics. Let’s get started!

I. What are non-woven fabrics?

1. What are non-woven fabrics?

As the name speaks for itself, non-woven fabric is a type of fabric produced without weaving or knitting. In contrast, it’s made by placing fibers together, and these fibers will be bonded by heating, chemicals, or pressure. The superior feature of this process is that although not being weaved or knitted, non-woven fabric has a cohesive fabric-like material.

2. Advantages of non-woven fabrics

So, why do people use non-woven fabrics widely in their daily life? The answer is because of some of the reasons followed:

- Elasticity and recoverability

- Enhanced absorbency

- Washability

- Ventilation

- Filtration

- Bacterial protection

- Waterproof

- Impact resistance

- Flame retardancy

- Electrical insulation

- Heat preservation

- Non-disheveled

- Easy to produce and process (compared to textile fabrics)

- Affordable price

You may be interested in:

- HD filler masterbatch: 4 most common applications in the plastic industry

- What is bio filler masterbatch and how is it applied in the plastic industry?

II. Producing pp non-woven fabric using PP filler masterbatch

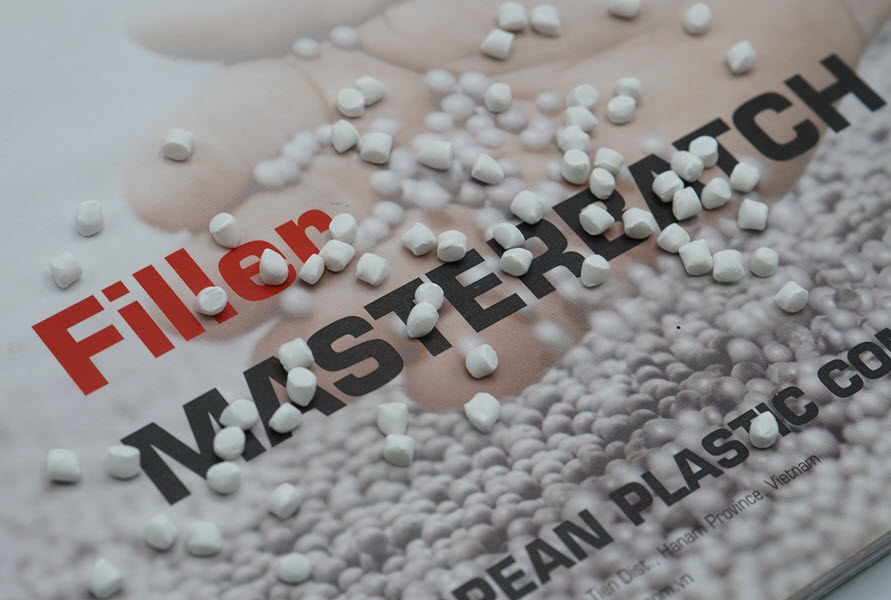

1. What is PP filler masterbatch

PP filler masterbatch is the combination of Calcium Carbonate, Polypropylene (PP), and other additives. Basically, the natural color of the PP filler masterbatch is white, and the color dispersion is quite stable. Based on the quality expectation, each manufacturer will have its custom formula to produce PP filler masterbatch.

Nowadays, almost all PP non-woven manufacturers use this material to produce PP non-woven and FIBC bags. It’s the superior solution due to some of the benefits as followings.

2. The benefits of using PP filler masterbatch for PP non-woven

- Cost effectiveness: because PP filler masterbatch will replace around 40-50% of the resin, we will save a considerable amount of money (the cost of resin is much more expensive than that of PP filler masterbatch). Reducing cost also means that manufacturers can set a competitive price for their final product.

- Enhanced mechanical properties: some advantages of PP non-woven fabric are strength, excellent elongation, enhanced opacity/matte, and cotton-soft feel.

- Productivity improvement: A characteristic of PP filler masterbatch is good thermal conductivity. Therefore, this material needs a lower processing temperature and shortens the product cycle. As a result, we can save tons of energy and speed up our working process.

- Printability: one of the most popular applications of non-woven fabrics is to create bags gloves, caps, and shoes,... which require aesthetically printed patterns. Therefore, manufacturers mix PP filler masterbatch to the ingredient to enhance the printability of non-woven fabrics.

- Environmental harmlessness: PP filler masterbatch will replace a large amount of resin which releases carbon footprints when manufacturing.

III. Where to buy PP filler masterbatch?

Nowadays, there are a lot of PP filler masterbatch suppliers in the market. That means you may lose a step in the dark ocean of poor-quality products. A suggestion for you is that you should choose a manufacturer who is reliable and has years of experience in the field.

EEuropean Plastic Company (EuP) is the world’s largest filler masterbatch manufacturer located in Vietnam. Our PP filler masterbatch is a quality-proven product that satisfied thousands of customers in +85 countries all around the world. This product is a cost-effective solution and helps you enhance many properties of your final products like brightness, opacity, and shrinkage reduction.

EEuropean Plastic Company (EuP) is the world’s largest filler masterbatch manufacturer located in Vietnam. Our PP filler masterbatch is a quality-proven product that satisfied thousands of customers in +85 countries all around the world. This product is a cost-effective solution and helps you enhance many properties of your final products like brightness, opacity, and shrinkage reduction.

If you want to get more details about our PP filler masterbatch, please fill in this form or contact us via email/phone number. Any questions and product inquiries are welcome!