Plastic bags may be one of human being’s current obsession, which is rather controversial when discussing. Everyone knows that plastic bags are very hard to degrade and have environmental drawbacks. But why do people still use them? In this blog, we’ll explain what plastic bags are, the effects of plastic bags on the environment, and propose a solution to alleviate the problem.

Let’s dive right in!

1. What are plastic bags?

Plastic bags (also known as poly bags or pouches) are containers or packaging made from a combination of resin and additives. The most common materials to produce plastic bags are Polyethylene which is produced from crude oil or natural gas. Typically, plastic bags are thin, light, transparent (or semi-transparent), strong, and waterproof.

Although we’re trying to replace plastic bags with other forms of packaging like fabric bags, and tree leaves,...the consumption of plastic bags used per year is approximately 5 trillion units due to their following superior features:

- Cheap: To produce plastic bags, we need less material, energy and time than other types of packaging like fabric bags, boxes, cartons, or jars,... Therefore the price of plastic bags is incredibly cheap which helps the manufacturers/sellers reduce a considerable amount of cost.

- Versatile and durable: Thanks to their light property, plastic bags are convenient to take to everywhere. In fact, the plastic bag weighs 6-8 grams and can carry approx 6kgs or 1000 times their own weight.

- Weatherproof: Because plastic bags are very hard to tear or break down in any weather condition, people make use of them to protect content from rain or water.

2. How were plastic bags invented?

The story began in 1933 when Polyethylene was created by accident at a chemical plant in Northwich, England. Seeing its potential, the British military used it secretly during World War II.

From the early 1950s, Americans and Europeans started using plastic to produce composite constructions with handles fixed to bags in a secondary manufacturing process.

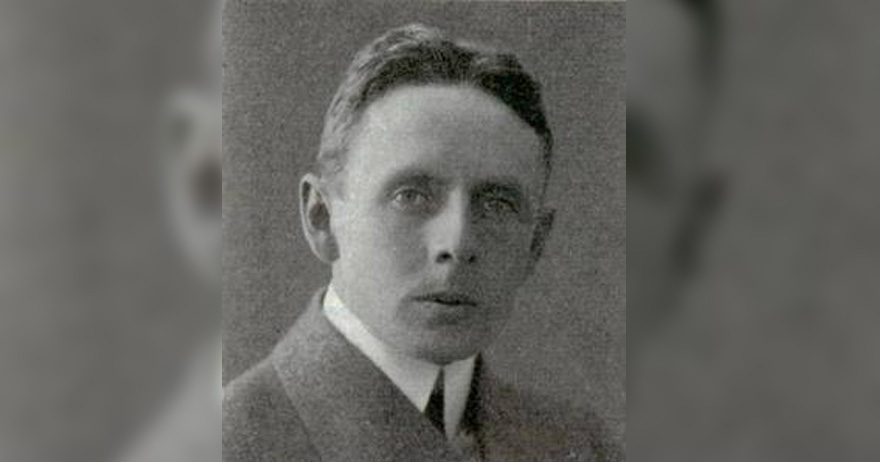

But the person who invented our today lightweight plastic bags is a Swedish engineer named Sten Gustaf Thulin. In the early 1960s, Thulin created a solution for a packaging company in Sweden by folding, welding, and die-cutting a flat tube of plastic. His final result was a container that is strong with a high load-carrying capacity. The invention was patented worldwide by Celloplast in 1965.

Sten Gustaf Thulin

It was not until the mid of 1980s that plastic bags appeared in every household in the developed world. At that time, the use of plastic bags started being a controversial and highly publicized dispute among people. However, today we still use them as one of the most common packaging and containers that have been a part of our life.

3. The effects of plastic bags on the environment

To be honest, plastic bags are kind of never-fully-breakdown, if so, it takes thousands of years. Some of the plastic bags’ impacts on the environment are:

- Causing the death of animals, especially sea animals which mistake them for food.

- Taking up to 2000 years to completely decompose.

- Storing toxic chemicals that emit into the environment during manufacturing and the degradation process.

- Blocking the drainage system.

- Resulting in pollution of groundwater.

4. So,...how to address the problem

Although the government and many other associations encourage people to use eco-friendly alternative bags made from fabric, natural fibers, and paper, it seems that plastic bags are something irreplaceable. Another solution to this problem is to improve the properties of plastic bags, like enhancing their degradability, for example. In fact, today there are many plastic bag manufacturers mixing bio filler or bioplastic compounds in the ingredients to boost the biodegradability of their products.

EuP Bio filler

Bio filler is a cost-effective material solution for bioplastic end-products. It helps save production costs for bioplastic bags, improve several properties, enhance biodegradability, and act as an anti-block and slipping agent in the blown film (the technology usually applied in producing plastic bags).

EuP bioplastic compounds

Bioplastic compounds are a green material solution that enables plastic bags to be biodegradable within 12 months. The difference between bio-plastic compounds and bio-filler is that you don't have to mix the bio-plastic compound with any other materials. Such an all-in-one solution!

Using bio-plastics to manufacture plastic bags is not only an incredible way to protect the environment but also helps businesses define their corporate social responsibilities (CSR). Plastic bags are not totally harmful. We believe that when we use them correctly and thoughtfully, all of us can live in happy harmony.

5. Where can you buy plastic materials?

European Plastic Company (EuP) is the world’s largest filler masterbatch manufacturer located in Vietnam. Our bio filler and bioplastic compounds are quality-proven products that satisfied thousands of customers in +85 countries all around the world. This product is a perfect alternative to virgin resin to enhance degradability, save cost and protect the environment.

If you want to get more details about our products, please fill in this form or contact us via email/phone number. Any questions and product inquiries are welcome!