ABS engineering plastic is a very familiar name in many different industries. It is considered the thermoplastic used for almost anything. So, what advantages does it possess that make manufacturers choose it? The following article will provide readers with detailed information about the concept, outstanding properties, and applications of ABS engineering plastics in real life to understand why it is one of the most popular plastics on the market today.

1. ABS engineering plastic - what is it?

ABS stands for Acrylonitrile Butadiene Styrene, formed by the polymerization of acrylonitrile, butadiene together with styrene. The acrylonitrile in ABS increases chemical resistance, wear resistance, heat resistance, and hardness. Styrene makes ABS shiny and easy to work with. Butadiene in ABS is a rubber substance that helps ABS plastic tough and malleable at low temperatures.

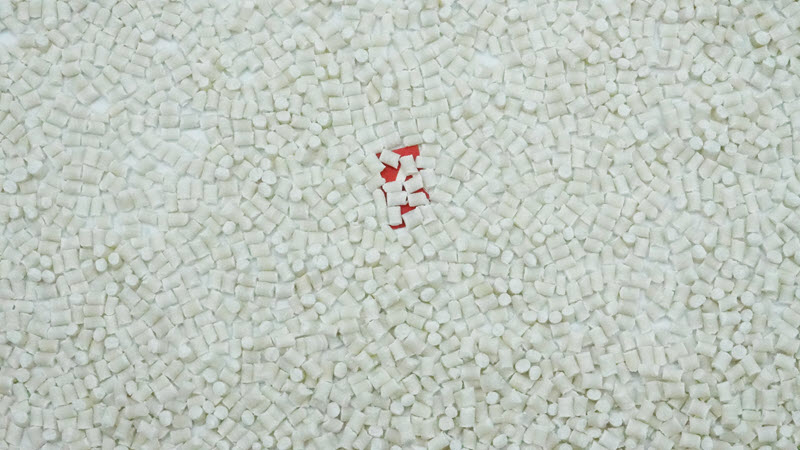

ABS plastic is a thermoplastic and amorphous polymer with an opaque color. Since it is a thermoplastic material, it can be easily recycled.

What is ABS engineering plastic

2. ABS engineering plastic properties

2.1. Stiffness

Thanks to its unique composition, ABS plastic is a material with high durability, dimensional stability, and bearing capacity. It has become a widely applicable material in our life.

2.2. Excellent impact resistance

Due to its stiffness property mentioned above and non-brittle property, ABS plastic has superior impact resistance compared to other plastics. It is not afraid of damage during transportation. Thanks to this advantage, ABS plastic is a popular material for items that need high bearing capacities such as suitcases and plastic cabinets,...

ABS plastic has superior impact resistance compared to other plastics

2.3. Good dimensional stability

Since the chemical compositions in ABS engineering plastic make it heat and chemical-resistant, it is less shrinkage by external influences and has good dimensional stability.

Related:

2.4. Good heat resistance

ABS plastic also has another advantage which is resistance to a certain amount of heat, specifically below 90 O C. In daily life applications, 90 O C is more than enough to ensure durability for items.

2.5. Good electrical insulation

This is a type of plastic extensively applied in the electrical and electronic industries because of its excellent electrical insulating ability.

In addition, its toughness, heat resistance to a certain extent, and stable dimensions make this plastic an ideal choice for making semiconductor materials.

2.6. Waterproof and wear resistance

ABS plastic's ability to absorb water is quite low, plus this plastic is not abrasive by external impacts. Therefore, people apply these two advantages of ABS plastic to alternate wooden doors in the construction industry. It helps to reduce the risk of water penetration leading to damage like wood-based panel doors.

ABS plastic door

3. Types of ABS engineering plastic compound

Besides the advantages, any material has its drawbacks, ABS plastic is no exception. Therefore, in order to strengthen the characteristics of ABS plastic further for applications in various fields, engineering plastic compounds were born to solve these problems. Let's take a look at some typical ABS engineering plastic compounds below.

Types of ABS engineering plastic compound

ABS Glass fiber compound is a product that combines ABS resin with glass fiber reinforcement and some other additives to increase the hardness and deformation temperature of ABS plastic. The application of this compound is in equipment that requires higher rigidity and temperature than those that only serve under normal temperature conditions.

ABS glass fiber compound

In the electrical and electronic industry, electrostatic discharge can cause damage or malfunction of electronic molecules, microchip assemblies, or even a complete device.

ABS Antistatic compound is a combination of ABS plastic with antistatic additives, namely carbon black conductive. This compound has extensive applications in the electrical and electronic industry to help limit the aforementioned electrostatic discharge.

ABS flame retardant compound is a blend of ABS resin with flame retardant additives with flame retardant according to different standards.

ABS flame retardant compound is intended to increase the fire resistance of ABS plastic devices such as power sockets, phone chargers, and electronic devices,... In case the temperature exceeds the resistance of these devices, they only heat up and melt, not lead to burn and spread of fire to other items.

ABS flame retardant compound

4. Application of ABS engineering plastic

4.1. ABS earphone

ABS plastic is a great choice for making lightweight yet sturdy earphone covers. Because of small and easy-to-fall items like earphones, if you accidentally drop them and step on them, this is very easy to cause breakage. So, thanks to the good impact resistance and high hardness of ABS plastic, you don't have to spend money constantly on new earphones.

Moreover, ABS plastic is more suitable for making earphone covers, especially for Bluetooth earbuds, than metal because plastic material will not affect radio waves - the way Bluetooth devices work.

ABS earphone

4.2. ABS plastic car parts

With outstanding properties, including heat and impact resistance and lightweight, ABS thermoplastic is an excellent material alternative to metal. It is suitable to manufacture car parts such as bumpers, grilles, wheels, door handles, mirror covers, automotive fuel covers, and many other applications in the automotive industry.

ABS plastic helps significantly reduce vehicle weight leading to increased fuel efficiency, thereby reducing CO2 emissions into the environment. Today, with the increase of car users around the globe, the proportion of the ABS plastic industry is increasing.

ABS plastic car parts

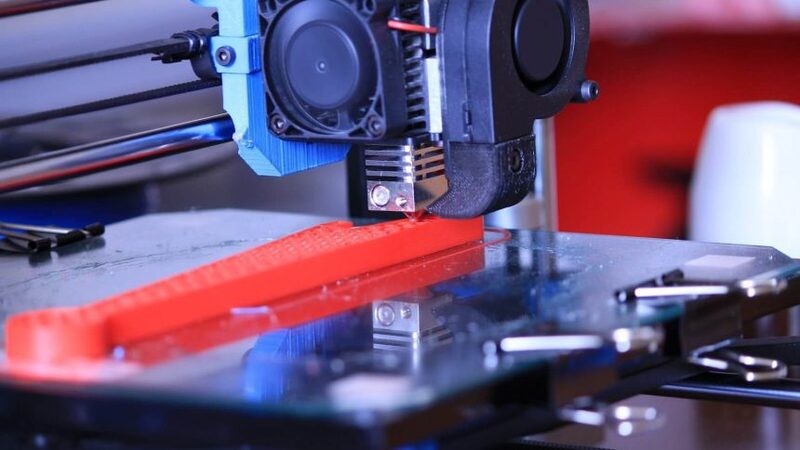

4.3. ABS plastic 3D printer

ABS was one of the first plastics used in the 3D printing industry. Today, ABS remains a popular material in this industry due to its low cost, good mechanical properties, and can be easily molded to produce the desired shape. ABS plastic allows printing products with high strength and good wear resistance during usage time.

ABS plastic 3D printer

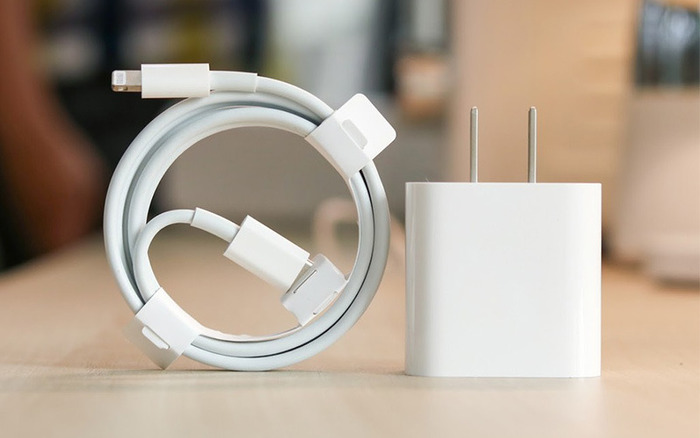

4.4. ABS mobile charger

Thanks to its good antistatic, flame retardant, and low cost, ABS engineering plastic compound is a material that cannot be more suitable to produce low-cost devices such as mobile chargers.

ABS mobile charger

4.5. ABS power socket

Flame retardant is the feature that users are most interested in when buying electrical devices, including electrical outlets. Therefore, for manufacturers of household electrical appliances, ABS flame retardant compound with excellent fire resistance is a commonly used material to make power sockets.

ABS power socket

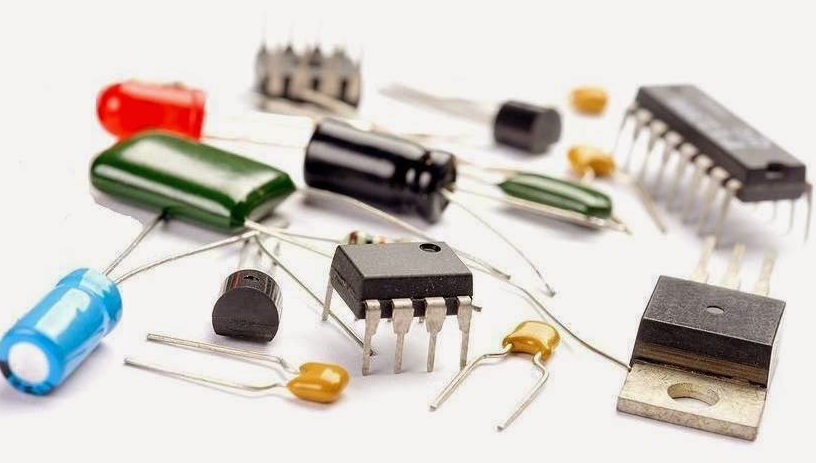

4.6. ABS electronic component

Good electrical insulation is the key property for ABS plastic to be widely used in making electronic components. In addition, flame retardant and antistatic are also two advantages for this plastic to become the first choice in the electronic industry.

ABS electronic component

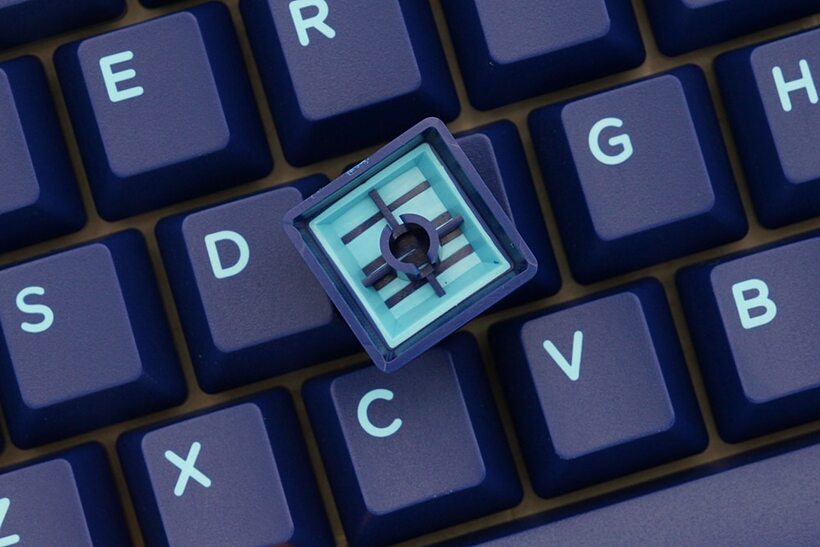

4.7. ABS keyboard

The computer keyboard is a prominent application of ABS engineering plastic. In a computer, the keyboard is the part that is used most often and continuously. With good wear resistance and high durability, ABS plastic makes computer keyboards less likely to wear out by typing continuously for many years.

ABS keyboard

If you are looking for top-quality ABS engineering plastic compounds, contact EuroPlas today. Our experienced team is ready to discuss your requirements and provide customized solutions tailored to your specific needs.