Have you heard of PEKK plastic? It's quietly making an impact in industries all around us. While its market may seem relatively small at $54 million by 2022, PEKK's versatility and utility are undeniable.

Developed in the 1960s, PEKK has gained popularity in recent years, finding use in everything from aerospace components to medical implants.

So, what is the big deal with PEKK? So, let's break it down. Are you prepared to explore PEKK plastic in more detail? Let's examine why learning more about this seemingly inconspicuous material is worthwhile.

1. What is PEKK plastic?

From concept to reality, exposing PEKK plastic's manufacturing enchantment.

First and foremost, let’s break into each character of PEKK. PEKK stands for Poly-Ether-Ketone-Ketone. It is one of the most high-performance thermoplastic polymers from the polyaryletherketone (PAEK) family.

With its distinct chemical structure, which includes a strong chain made up of building blocks known as aryl ketone units joined together by ether and ketone groups. PEKK's exceptional mechanical strength and thermal stability are attributed to this unique structure.

PEKK is used in a variety of industries, including engineering, aerospace, automotive, and medical implants. Its resistance to severe temperatures, strong chemicals, and heavy loads makes it an excellent choice for challenging environments.

PEKK's dependability and performance have resulted in broad acceptance in crucial industries where durability, resistance, and longevity are essential.

2. Properties of PEKK plastic

Collaborating with industries to unlock the full potential of PEKK plastic.

2.1. Mechanical Strength:

PEKK boasts an impressive tensile strength ranging from 70 to 150 MPa, making it resilient and capable of handling hefty loads. This means it can withstand forces equivalent to lifting a car without breaking a sweat.

Its robust mechanical properties make it a go-to choice for applications requiring durability and reliability, such as structural components in aerospace and automotive industries.

2.2. Stiffness:

PEKK is extraordinarily strong and deformation-resistant, with a flexural modulus that ranges from 2,800 to 4,000 MPa; it resembles the structural backbone of a skyscraper.

Because of their rigidity, PEKK components are guaranteed to keep their structural integrity and shape even in the face of harsh loads and weather. Thanks to its stiffness, PEKK is a reliable material that can withstand the pressures of high-speed machinery and support the weight of a building.

2.3. Temperature Resistance:

PEKK is appropriate for temperatures up to 260°C since it can tolerate temperatures between -70°C and 260°C without losing its mechanical qualities.

PEKK maintains its strength and stability across a variety of circumstances, guaranteeing dependable performance from the bitter cold of Arctic expeditions to the searing heat of industrial processes.

2.4. Chemical Resistance:

Comparable to stainless steel, PEKK has outstanding resistance to a variety of chemicals, including bases, acids, solvents, and oils. Because of its chemical inertness,

PEKK is perfect for uses including oil and gas exploration, chemical processing, and under-the-hood automotive components, where exposure to corrosive substances is expected.

2.5. Electrical Properties:

With a dielectric constant of approximately 3.2 and a volume resistivity of up to 10^15 ohm-cm, PEKK is a great electrical insulator, which makes it perfect for electrical and electronic applications.

PEKK is appropriate for use as an insulator against electrical currents and a stopper of electrical leakage in circuit boards, high-voltage equipment, and electronic devices.

2.6. Biocompatibility:

After undergoing extensive testing to ensure biocompatibility, PEKK satisfies many strict standards, guaranteeing its safety for use in medical devices and implants.

PEKK is a material that is perfect for orthopedic implants, dental prostheses, and surgical tools since it is human body compatible. This gives patients peace of mind and confidence in the material's ability to perform for medical experts.

Let's highlight the advantages and disadvantages of PEKK in summary.

Pros:

- Elevated mechanical strength

- Outstanding thermal stability

- Chemical resistance

- Biocompatibility

Cons:

- Cost: Since they are more costly than traditional thermoplastics, their use in situations where cost is a factor is restricted.

- Processing complexity: Requiring specialist equipment, processing can be challenging due to high melting temperature and viscosity.

- Limited color selection: Primarily offered in natural or black, may not satisfy all aesthetic standards.

- Thermal expansion: Precision components that experience temperature variations may experience warping and dimensional changes due to their relatively high coefficient of thermal expansion.

3. Applications of PEKK plastic

3.1. Aerospace:

PEKK revolutionized aerospace engineering with lightweight, high-performance materials

PEKK is the material of choice for aerospace components that are exposed to harsh environments because of its remarkable endurance and thermal stability. It is frequently used in structural components that need to be lightweight but strong to ensure maximum performance and safety, as well as engine parts, where high temperatures and mechanical stress are typical.

3.2. Automotive:

PEKK finds use in under-the-hood and high-performance engine parts in the automotive industry. It is appropriate for usage in vital parts including intake manifolds, fuel system components, and valve covers due to its resistance to heat, chemicals, and mechanical stress.

PEKK offers dependable performance and durability in automotive applications because of its resistance to hostile conditions.

3.3. Chemical Processing:

Because of its resilience to chemicals, PEKK is a good choice for use in chemical processing settings where exposure to caustic materials is frequent. It is frequently used on gaskets, seals, and other parts that come into contact with strong chemicals.

In chemical processing plants, the integrity and dependability of vital systems and equipment are guaranteed by PEKK's capacity to retain its qualities in such conditions.

3.4. Electronics:

PEKK is perfect for use in electrical components and devices that need insulation under pressure because of its superior electrical insulation qualities.

It is frequently employed in places where dependable electrical insulation is necessary to guarantee the correct operation and security of electronic systems, such as connectors, insulating bushings, and circuit boards. In the electronics industry, PEKK is a desirable material due to its ability to sustain high voltages while maintaining dimensional stability.

3.5. Medical:

Biocompatible PEKK material is transforming medical implants and enabling the healthcare sector.

Because of its biocompatibility, PEKK can be used in surgical equipment and orthopedic implants, among other medical devices. The FDA (Food and Drug Administration) has acknowledged this material, which is ideal over titan for implants such as dental implants, joint replacements, and spinal cages due to its biocompatibility and seamless integration with surrounding tissues.

In addition to providing superior mechanical qualities for long-term implant performance, PEKK's biocompatibility guarantees patient safety and comfort.

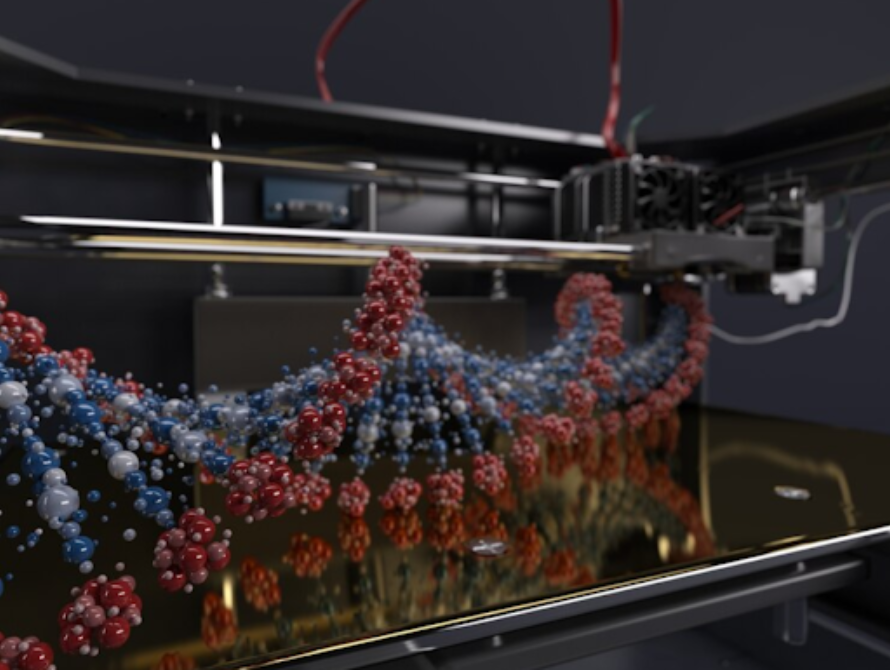

3.6. 3D printing

An intriguing advancement in additive manufacturing has been the use of PEKK in 3D printing. PEKK is a high-performance thermoplastic polymer that has various benefits for applications involving 3D printing.

Printing components that can tolerate high temperatures without deforming or deteriorating is made possible by PEKK's remarkable thermal stability.

In general, the ability of PEKK to work with 3D printing procedures creates new opportunities for using additive manufacturing technology to create intricate and high-performing components.

4. Are PEKK and PEEK related?

Yes, PEKK (Polyetherketoneketone) and PEEK (Polyetheretherketone) are related as they both belong to the family of polyaryletherketones (PAEKs). Despite their similar names, they have distinct chemical structures and properties as a result of this structural variance.

PEEK is made up of ether and ketone group repeating units, while PEKK has two ketone groups in each repeating unit.

PEEK is well-known for having a high melting point, outstanding chemical resistance, and biocompatibility, which make it ideal for a range of uses in the electronics, automotive, aerospace, and medical sectors.

However, in comparison to PEEK, PEKK has even greater mechanical strength and thermal stability, which makes it especially suitable for demanding applications in the automotive, oil and gas, and aerospace industries.

Here's a comparison table detailing the properties of both PEKK and PEEK:

| Property |

PEKK (Polyetherketoneketone) |

PEEK (Polyetheretherketone) |

| Chemical Structure |

Contains two ketone groups in each repeating unit |

Contains one ketone and one ether group per unit |

| Mechanical Strength |

High tensile strength (70-150 MPa) |

High tensile strength (90-100 MPa) |

| Flexural Modulus |

2,800 - 4,000 MPa |

3,500 - 4,000 MPa |

| Temperature Resistance |

-70°C to 260°C |

-70°C to 250°C |

| Chemical Resistance |

Resistant to acids, bases, solvents, and oils |

Resistant to acids, bases, solvents, and hydrocarbons |

| Electrical Insulation |

Excellent electrical insulation properties |

Excellent electrical insulation properties |

| Biocompatibility |

Meets standards for medical applications |

Biocompatible and widely used in medical implants |

| Applications |

Aerospace components, automotive parts, medical implants |

Aerospace components, automotive parts, medical implants |

Find out more about the differences between PEEK and PEKK plastics here: PEKK vs PEEK: Many differences you need to know

In conclusion, PEKK's adaptability and dependability make it a useful tool in the manufacturing of robust, high-quality components for a variety of industries, including electronics, medical, and aerospace and automotive.

PEKK presents certain limitations, such as restricted color options and processing complexity, but its advantages greatly exceed these, making it the material of choice for manufacturers looking to create products with exceptional endurance and performance.

5. About EuroPlas

As a trusted partner to many clients, EuroPlas provides comprehensive support and solutions, from material selection to customization and production. Because of its unrelenting dedication to client satisfaction and proven track record of exceptional delivery, organizations looking for high-quality materials for their applications tend to use EuroPlas.

For more information about our offerings, including cutting-edge solutions for your projects, visit our website at EuroPlas. Remember to take some time to go over our blog, which has a plethora of knowledge regarding plastics and business developments.