Heat resistant materials are increasing interest in applications where fire safety is important and high performance is required. These specialized materials have become essential components in many industries thanks to their ability to minimize the negative effects of fire and withstand high temperature environments.

Via this article, you will better understand the importance of flame resistant materials and new innovations in the future to help you have the most effective practical applications.

1. Current Landscape of Heat Resistant Materials

As science and technology continue to advance, heat resistant materials are becoming increasingly vital across a wide range of industries. From the high-risk environments of aerospace engineering to the critical needs of fire protection, these specialized heat resistant materials are playing a crucial role in ensuring safety, efficiency, and durability.

In the aerospace sector, hypersonic vehicles and reusable spacecraft require reliable fire-resistant composite materials to provide trusted thermal protection. Similarly, the energy and construction industries rely on flame resistant materials to create efficient and safe infrastructure.

2. Emerging Technologies of Heat Resistant Materials

Recent emerging technologies are driving the development of increasingly advanced heat resistant materials, which is expanding applications and innovations across industries ranging from aerospace and power generation to construction and more.

Read more: 5 common fire resistant plastics and how to enhance plastic fire resistance

2.1. Ceramic Matrix Composites (CMCs)

Ceramic Matrix Composites (CMCs) are advanced heat resistant materials that combine ceramic fibers and matrices to create exceptionally heat resistant and mechanically robust materials. The ceramic fibers provide enhanced strength and toughness, while the ceramic matrix protects the fibers and enables the material to withstand extremely high temperatures.

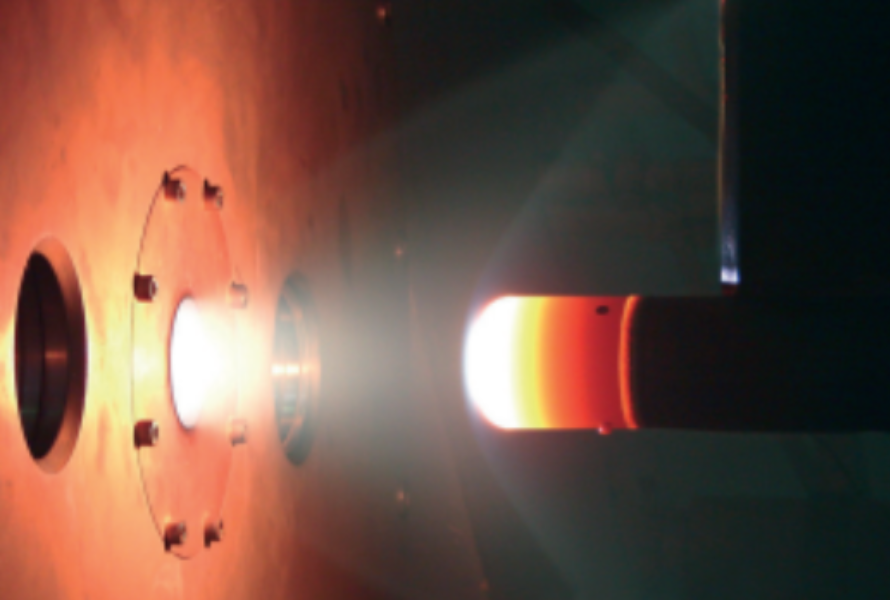

The synergistic combination of these components results in CMCs that can operate at temperatures exceeding 1,500°C, making them highly sought-after in aerospace applications such as jet engine components, thermal protection systems for hypersonic vehicles, and reusable spacecraft parts.

CMCs are cutting-edge heat resistant materials, engineered by integrating ceramic fibers and matrices.

2.2. High Entropy Alloys (HEAs)

High Entropy Alloys (HEAs) are a novel class of heat resistant materials composed of five or more principal elements in equal or near-equal atomic percentages, resulting in exceptional mechanical and thermal properties. HEAs are being explored for use in jet engine components, turbine blades, and other high-temperature structural parts.

HEAs have potential applications in power generation, where their ability as heat resistant materials to maintain mechanical integrity at elevated temperatures can contribute to the development of more efficient and durable energy systems.

2.3. Ultra-High Temperature Ceramics (UHTCs)

Ultra-High Temperature Ceramics (UHTCs) are heat resistant materials that can withstand temperatures exceeding 3,000°C, with exceptional thermal stability, high melting points, and superior mechanical properties.

UHTCs are particularly crucial for applications in hypersonic flight, where vehicles encounter temperatures upwards of 2,000°C during atmospheric re-entry. In addition to aerospace applications, UHTCs also find use in high-temperature industrial processes, such as cutting tools, furnace linings, and thermal management systems for power generation.

UHTCs are heat resistant materials capable of enduring temperatures beyond 3,000°C.

2.4. Functionally Graded Materials (FGMs)

Functionally Graded Materials (FGMs) are engineered with a continuously varying composition or microstructure, tailored to specific performance requirements, such as thermal resistance. FGMs can be designed with a high-temperature-resistant surface layer and a more ductile, lower-temperature core.

This heat resistant material is particularly useful for applications in aerospace, where thermal protection systems must cope with the intense heat generated during hypersonic flight or atmospheric re-entry. FGMs can also be employed in high-temperature industrial equipment, such as furnace linings, engine components, and thermal management systems.

2.5. Nanomaterials

Nanomaterials have opened new frontiers in heat resistant materials, with nanostructured ceramics, coatings, and reinforcements enhancing thermal stability, insulation, and fire resistance. The unique thermal properties of nanomaterials, such as carbon nanotubes and graphene, have led to their exploration in advanced thermal management systems.

The focus has been on the development of nanostructured ceramics, coatings, and reinforcements that can enhance thermal stability, insulation, and fire resistance. For example, the incorporation of ceramic nanoparticles or nanofibers into polymeric or metallic matrices can create composite materials with improved heat shielding capabilities.

Advances in nanomaterials have pioneered new horizons in heat resistant materials.

2.6. Smart Heat Resistant Materials

Smart Heat Resistant Materials are designed to actively adapt to changing environmental conditions, such as temperature fluctuations, by incorporating responsive elements that can trigger changes in the material's properties to better cope with heat. These materials represent a significant advancement in thermal management, with potential applications in building facades and aerospace thermal protection systems.

3. Future Applications of Heat Resistant Materials

3.1. Aerospace and Aviation

Heat resistant material composites will play a crucial role in aerospace and aviation, used to fabricate structural components for aircraft, spacecraft, and satellites that must withstand extreme temperatures and stresses. These advanced materials will also see increased use in aircraft interiors, providing fire-resistant seating, insulation, and wiring to enhance passenger and crew safety. As space exploration ventures deeper, heat shields and thermal protection systems made from cutting-edge heat resistant materials will be essential for shielding vehicles and payloads from atmospheric re-entry heat.

Heat resistant materials are crucial for aerospace and aviation, used to fabricate structural components.

3.2. Automotive and Transportation

The automotive and transportation sectors will widely adopt next-gen heat resistant materials. These advanced materials will manufacture engine, exhaust, and shielding components for enhanced fire protection and fuel efficiency. Lightweight, flame resistant composite body panels and parts will help automakers meet emissions goals without compromising performance or safety. In electric vehicles, heat resistant plastic housings will be critical for protecting batteries and electronics.

3.3. Electronics and Electrical Equipment

As electronics become more powerful, heat resistant materials will be vital for housings, enclosures, and insulation to protect against heat buildup. "Heat resistant" boards and connectors will enable reliable high-temp electrical and telecom infrastructure. The thermal stability and "flame retardancy" of these new plastics will ensure safety and reliability for critical electronic systems.

3.4. Construction and Building Materials

The construction sector will use heat resistant materials for safer, more durable structures. Polymer-based structural composites will enable taller, fire resistant buildings. Heat resistant panels, insulation, and roofing will improve fire resistance in buildings. Plastic piping, ducting, and other systems will provide enhanced safety and reliability for Heating Ventilating and Air Conditioning applications.

Heat resistant materials such as panels, insulation, and roofing will improve fire resistance in buildings.

4. Conclusion

Heat resistant materials are very important in industries, ensuring safety and efficiency. As demand increases, flame resistant materials will continue to be researched and develop advanced technologies, such as “smart” refractory materials to better adapt. These emerging innovations are driving the development of increasingly modern heat resistant materials that offer high applicability and enable innovation in aerospace, energy, construction, and more.

5. About EuroPlas’ flame retardant additive

Flame retardant materials from EuroPlas are designed to deliver a superior balance of impact resistance, thermal stability, dimensional stability, and scratch resistance. Some of the key features that set our offerings apart include:

- Limit the spread of fire by working on the plastic surface

- Good dispersion with most of standard resin

- No mechanical degradation caused to end-products

- Reasonable price

- No equipment corrosion

For comprehensive details about these flame retardant products, please contact us or visit our blog for more plastic industry information.