In today's highly competitive market, packaging is more than just a container; it's a powerful marketing tool. Choosing the right packaging plays a crucial role in product protection, customer attraction, and brand image building. Among the various packaging options available, woven PP packaging has gained increasing popularity due to its outstanding advantages. So, what makes woven PP packaging so special and widely trusted by businesses? Let's delve deeper with EuroPlas to explore and compare woven PP packaging with other packaging methods to make the best choice for your final product.

1. PP Woven Bag: Outstanding Features

To better understand PP Woven Bag and why it is becoming increasingly popular, let's delve into its definition, properties, and applications:

1.1. Definition of PP Woven Bag

PP Woven Bag is a type of packaging produced from polypropylene (PP) fibers through a weaving process. Polypropylene is a thermoplastic resin, primarily white or transparent, with high elasticity and excellent moisture resistance. The weaving process creates a sturdy fabric structure that offers good load-bearing capacity and durability.

PP Woven Bag is often in the form of large bags or sacks, widely used for packaging, transporting, and storing goods. They can be manufactured in various colors, sizes, and shapes to suit diverse needs.

1.2. Outstanding Features of PP Woven Bag

PP Woven Bag possesses several outstanding features such as high durability, reusability, and low production cost; specifically:

- High durability: PP Woven Baghas excellent load-bearing capacity and is resistant to tearing or puncturing. The woven structure helps to disperse the impact force, enhancing the packaging's durability. This effectively protects goods during transportation and storage.

- Reusability: One of the significant advantages of PP Woven Bag is its reusability. After use, they can be easily cleaned and reused without compromising quality. This not only saves costs but also contributes to environmental protection.

- Low production cost: Compared to many other types of packaging, the production cost of PP Woven Bag is relatively low. Polypropylene raw materials are reasonably priced, and the production process is simple and efficient. This reduces input costs for businesses and creates competitively priced products in the market.

Additionally, PP Woven Bag has other notable features such as:

- Light weight, reducing transportation costs.

- Excellent moisture resistance, protecting goods from moisture and mold.

- Easy to print and decorate, serving advertising and brand recognition purposes.

- More environmentally friendly than conventional plastic packaging due to its reusability and

- recyclability.

1.3. Common APPlications of PP Woven Bag

Agriculture:

- Packaging and transporting agricultural products such as rice, corn, beans, and grains.

- Storing fertilizers, pesticides, and other agricultural products.

- Used as bags for soil, sand, or gardening materials.

Construction:

- Used as sandbags for flood prevention or temporary construction reinforcement.

- Packaging and transporting construction materials such as cement, sand, and gravel.

- Storing and moving construction waste.

Food:

- Packaging and transporting dry foods like rice, flour, and sugar.

- Storing food ingredients during production and storage.

- Used as packaging for animal feed.

In addition, PP Woven Bag is widely used in many other industries such as:

- Textiles: Packaging and transporting textile raw materials and products.

- Chemicals: Containing and transporting powdered or granular chemicals.

- Recycling: Collecting and sorting recyclable waste.

With its diverse applications in many fields, woven PP packaging is increasingly affirming its important role in modern supply chains and logistics. The flexibility, durability, and cost-effectiveness of this type of packaging have made it the top choice for many businesses and industries.

See more: Using nonwovens in packaging is great for your business

2. Comparison of PP Woven Bag with Other Packaging Types

The following table compares woven PP packaging with other common packaging types:

| Criteria |

PP Woven Bag |

Paper Packaging |

Plastic Packaging |

Metal Packaging |

Durability

|

High |

Low |

Medium |

High |

Moisture Resistance

|

Good

|

Poor |

Good

|

Very good |

Reusability

|

High |

Low

|

Medium

|

High |

Production Cost

|

Low

|

Medium

|

Low

|

High |

Weight

|

Light |

Light |

Light |

Heavy |

Printability

|

Good |

Very good |

Good

|

Difficult |

Environmental Friendliness

|

Relatively good |

Good

|

Poor |

Good (if recycle)

|

Flexibility

|

High |

Medium

|

High |

Low

|

Food Preservation

|

Medium

|

Poor |

Good |

Very good |

Based on the comparison table, the main advantages and disadvantages of woven PP packaging can be summarized as follows:

PP Woven Bag can be reused and recycled, significantly reducing plastic waste. Its excellent moisture resistance ensures that goods are protected from moisture and mold, maintaining product quality during storage and transportation.

Economically, PP Woven Bag offers a competitive advantage due to its lower production cost compared to metal or paper packaging, and its reusability saves businesses significant costs in the long run. The high flexibility in design and production allows for packaging in a variety of sizes and shapes, optimally meeting the packaging needs of various industries.

Moreover, the light weight of PP Woven Bag not only reduces transportation costs but also facilitates the handling and movement of goods. Finally, the high durability of woven PP packaging ensures good load-bearing capacity, effectively protecting products throughout use and transportation, even in harsh conditions.

PP Woven Bag is not suitable for products requiring special preservation, and its food preservation capability cannot match that of specialized metal or plastic packaging. In terms of the environment, although it can be recycled, PP Woven Bag is not as biodegradable as paper packaging.

Additionally, this material has some limitations in terms of aesthetics and printability, which may not meet the requirements of high-end products or those requiring high-resolution designs.

In conclusion, PP Woven Bag is an excellent choice for many packaging applications, especially in industries requiring high durability, low cost, and reusability. However, the choice of suitable packaging still depends on the characteristics of the product, storage requirements, and specific usage purposes of each business. With the continuous development of technology, many manufacturers are striving to improve these limitations, promising to provide more comprehensive PP Woven Bag solutions in the future.

See more:

5 types of plastic masterbatch are mainly used for packaging production

Errors You Need To Avoid In Plastic Packaging Production

3. Conclusion

Through the comparison of PP Woven Bag with other packaging types, we can clearly see the outstanding advantages of woven packaging in many aspects. PP Woven Bag not only provides high efficiency in product protection but also meets the requirements of sustainability and environmental friendliness. The flexibility in design and reusability of woven packaging are also significant advantages, helping businesses save significant costs in the long run. However, the choice of suitable packaging still depends on the product characteristics, transportation requirements, and marketing goals of each business. In the context of increasing emphasis on environmental protection, woven packaging is gradually affirming its position as an effective and sustainable packaging solution for the future.

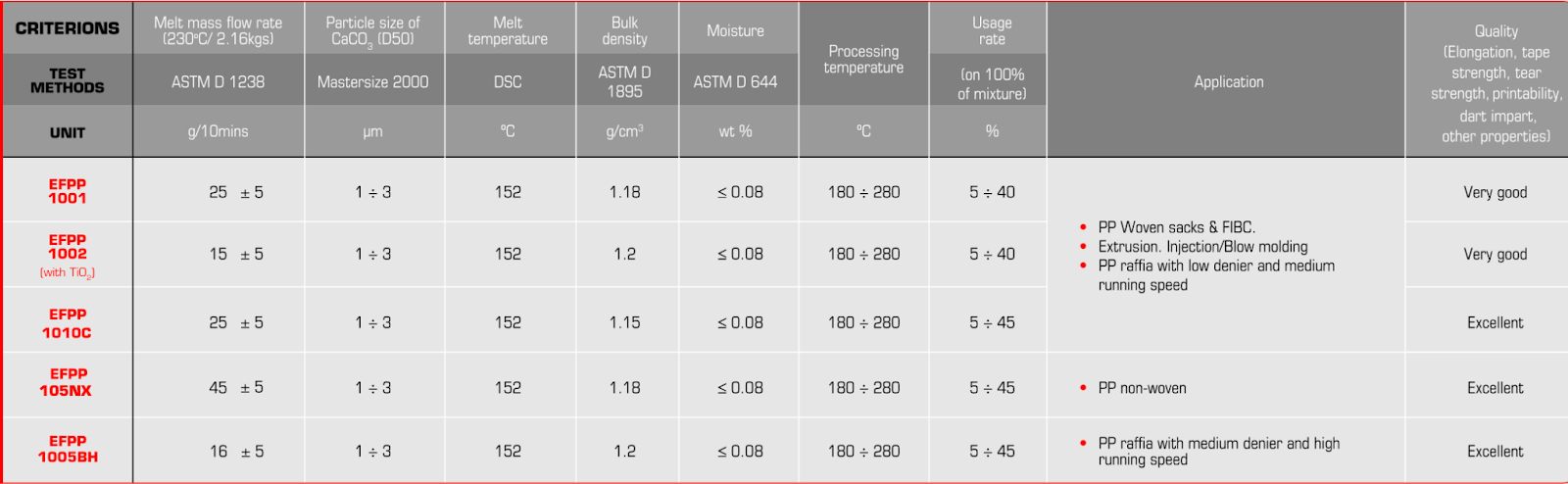

4. About EuroPlas’ PP Products

EuroPlas, a leading global supplier of filler masterbatch products, has continuously innovated and developed high-quality PP Woven Bag products. In particular, the company focuses on developing advanced solutions for the woven packaging industry, meeting the growing demands of the market.

EuroPlas’ PP filler masterbatch is a perfect combination of calcium carbonate (CaCO3) filler, PP base resin, and specialized additives. PP filler masterbatch offers numerous advantages, such as:

- Cost optimization

- Diverse applications

- Flexible customization

- Improved mechanical properties

- Enhanced production efficiency

In terms of packaging, EuroPlas’ PP products are carefully packed in 25kg PP/PE bags or jumbo bags according to customer requirements. This helps to better preserve the raw materials and facilitates transportation and use in the woven packaging production process.

Regarding processing, with a flexible temperature adjustment range from 140°C to 280°C, EuroPlas’ PP products are well-suited for various types of woven packaging machinery and production processes. This helps manufacturers optimize their processes and ensure the stable quality of the final PP Woven Bag product.

In summary, EuroPlas’ PP products not only meet the excellent needs of the PP Woven Bag industry but also bring significant added value to businesses, from cost savings to product quality improvement.

See more:

4 types of filler masterbatches recommended for packaging industry

For prompt and accurate advice on EuroPlas’ PP products, especially for applications in the woven packaging field, please leave your detailed information via the

form. Alternatively, you can contact EuroPlas’ consulting experts

directly via the provided phone number or email. EuroPlas is committed to responding as soon as possible to meet your needs in the most effective way.