-is-a-fluoropolymer-with-many-useful-properties.png)

Fluorinated Ethylene Propylene (FEP) is a Fluoropolymer with many useful properties

Fluorinated Ethylene Propylene (FEP) resin is a Fluoropolymer with many useful properties for the manufacturing industry. In fact, FEP plastic is a version that inherits most of the advantages of PTFE. Manufactured from hexafluoropropylene and tetrafluoroethylene and they have a very similar composition to PTFE but are much softer. Therefore, FEP plastic can be melted to make it more convenient for diverse shaping processes. A quick summary of FEP plastic is that they are transparent and have the ability to withstand sunlight for a long time. Let's learn in detail about the definition of FEP plastic and take a look at some of the outstanding features of this product line right now!

1. What is FEP plastic?

FEP is the copolymerization between hexafluoropropylene and tetrafluoroethylene

Fluorinated Ethylene Propylene Resin is known by the abbreviation FEP. FEP plastic is also one of the fluoropolymers. This is the result of free-angle copolymerization between a mixture of hexafluoropropylene and tetrafluoroethylene. In fact, FEP was developed to inherit the properties of PTFE.

2. Properties of FEP plastic

FEP plastic is composed of carbon and fluorine atoms because the FEP chemical structure is a fluoropolymer. FEP is a copolymer of hexafluoropropylene (HFP) and tetrafluoroethylene (TFE). The outstanding characteristics of FEP plastic can be mentioned as follows:

FEP will become virtually invisible in water because they have the lowest rated refractive index

- Temperature range: FEP plastic can withstand a temperature range of 200°C to +205°C (-328°F to +401°F). This range is shown to be lower than ETFE and PFA resins.

- Transparency: FEP will become virtually invisible in water because they have the lowest rated refractive index among Fluoropolymers. This gives FEP low light reflection and excellent optical clarity. FEP plastic's ability to transmit UV rays is very good, up to about 98% thanks to its high transparency. Thanks to this characteristic they are suitable for applications requiring good light transmission.

- Durability: As for FEP plastics, they have a high dynamic friction coefficient, are flexible and have quite good tensile strength. However, they cannot withstand repeated folding over a long period of time.

- Melting point: FEP plastic has a melting point of 260 degrees C (500 degrees F), which is considered quite low. Compared to PFA, the melting point of FEP is about 40 degrees Celsius lower, and also lower than PTFE. However, for technical processing processes that require not too high temperatures, FEP plastic will also be an advantage compared to the above types.

- Chemical resistance: FEP has good chemical resistance, making it effective in applications that require contact with corrosive chemicals or solvents. Under conditions of exposure to harsh environments, FEP plastics are still able to retain their unique properties quite perfectly. For example, in direct light environments or harsh weather, FEP plastic still retains its non-stick properties and transparency quite impressively. Besides, FEP plastic has a pure carbon-fluorine structure and is fully fluorinated, so it can resist the caustic agents of PTFE.

- Human-friendly: the safety and no harm to human health of FEP plastic has been approved by the FDA. In addition, FEP resin is a fluoropolymer with excellent electrical insulating properties. FEP is one of the more non-linear conductors of electrostatic fields thanks to FEP's fairly high dissipation (about six times that of PFA and EFTE).

3. Applications of FEP plastic

FEP plastic gives laboratory instruments the ability to resist chemical attack

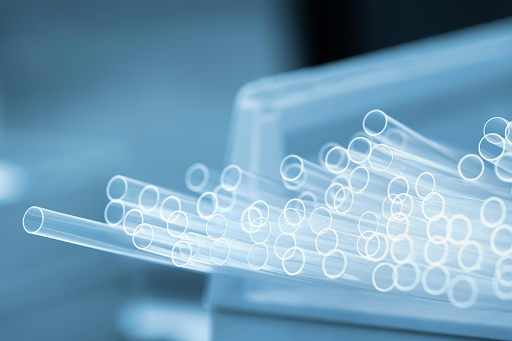

- Plastic pipe production: FEP plastic plays a key role in many plastic pipe production processes. Thanks to its softness and malleability, FEP plastic is used to produce plastic pipes of a variety of sizes and shapes. Some outstanding internal advantages of FEP plastic pipes include transparency, ease of rolling, chemical resistance, weather resistance, good electrical insulation and a relatively wide thermal operating range.

- Chemical research industry: plastic pipes and laboratory tools manufactured from FEP plastic meet the needs of experimental processes that require transparency and chemical resistance of the tools. In addition, FEP plastic gives laboratory instruments the ability to resist chemical attack by some highly corrosive acid solvents during research involving corrosive experimental processes. FEP resin also has the potential to serve as a sample holding material in microscopy applications. They have the lowest rated refractive index among Fluoropolymers providing FEP low light reflection and excellent optical clarity. Therefore, FEP plastic contributes to minimizing blur due to optical aberrations when light passes through the sample container.

- Chemical processing industry: FEP plastic is used to produce applications such as round bars, shields, air purifiers, tank linings or tank walls used specifically for transport and treatment processes chemicals which are highly corrosive and toxic.

- Aerospace industry: FEP plastic will be an optimal choice for applications that require a quality composite part. Specifically, FEP plastic can satisfy a number of aerospace components thanks to its ability to maintain chemical stability under harsh conditions such as weather or chemical fuels. For example, FEP resins can be used to fabricate "release films" and are intended to prevent curing adhesive polymers (e.g., epoxy in carbon fiber/epoxy composite panels) from bonding to the vacuum packaging material.

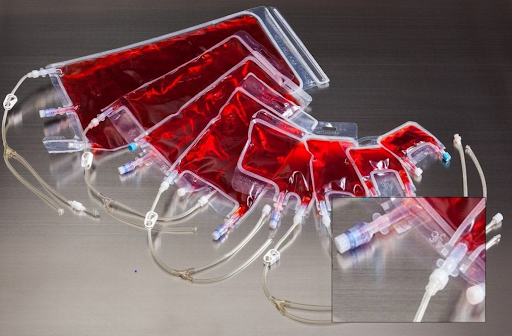

- Some other applications made from FEP plastic include: conventional wire insulation, sheathing for telephones and common primary wires, valve & chemical equipment lining, heat shrink tube & non-shrink tube , heat exchanger, medical tube etc

In summary, FEP plastic is one of the fluoropolymers that is increasingly of interest in many production technology industries today. They inherit the properties of PTFE and exhibit some outstanding properties such as transparency, weather resistance, durability and non-toxicity. Manufacturers can make optimal use of the characteristics of FEP plastic in projects that produce round tubes, laboratory instruments and a number of other technical components.

4. About EuroPlas

EuroPlas will be a perfect choice for your needs of finding a high quality plastic supplier. You can easily search for high-quality and reliable lines of colored resins, fillers, additives, bioplastics and biofillers at our website. Moreover, stay tuned for more useful shared articles from EuroPlas today! We are proud to always be a fast and reliable source of updated information for your production plans!