In this overview, we will explore the advantages of HIPS filler masterbatch, how to choose the right one, and its diverse applications in the plastic market. Understanding these aspects will help manufacturers leverage this material to improve product quality and operational efficiency.

Read more: What is filler masterbatch and how it is applied to your production?

1. What is HIPS Filler Masterbatch?

HIPS filler masterbatch is a highly concentrated combination of CaCO3, HIPS resin and other additives.

This masterbatch is intended to improve the physical characteristics of the final products while simultaneously retaining the possibility of processing plastics. Additionally, their use is widespread in order to increase strength and rigidity, as well as to reduce the cost of various plastic products.

HIPS filler masterbatch is used to enhance physical properties of end-products.

2. Advantages of Using HIPS Filler Masterbatch

HIPS filler masterbatch offers several benefits that enhance the performance and cost-effectiveness of plastic products. Here are some key advantages:

- Cost efficiency: The use of HIPS filler masterbatch offers the possibility of a considerable decrease in the material cost. With the help of a filler, producers can decrease the amount of costly resin whilst still retaining the appropriate characteristics of an end product.

- Improved mechanical properties: HIPS filler masterbatch improves the mechanical properties and the impact properties of the plastics products. Of these two improvements, the second is more useful in cases where the composite must be hard and resistant.

- Enhanced processability: HIPS filler masterbatch enhances the processability of the polymers during material processing stages. Mold filling and consistency are also improved in the process as this approach minimizes major sources of production deficiencies and increases the efficiency of the process.

- Versatility: HIPS filler masterbatch is compatible with a wide range of polymers, suitable for various applications of packaging & car, industries, and general consumer products.

- Reduced weight: By partially replacing the resin, products that have lower weights that do not cause a reduction in mechanical characteristics can be obtained. This is especially helpful in industries with waste minimization and energy management strategies at the core of their operations.

- Customization options: Another advantage of HIPS filler masterbatch is that it can be formulated with specific fillers and additives that will cater to special performance characteristics such as UV stability or color solutions making it easier to set an end-product that stands out.

- Environmental benefits: Implementation of the HIPS filler masterbatch can assist in minimizing the amount of the required plastic resin thus minimizing the consumption of material and perhaps aiding in minimizing the amount of harm that is done to the environment by plastic manufacturers.

- Improved surface finish: The incorporation of HIPS filler masterbatch improves the surface finish of the molded products and gives them a smoother surface look.

Numerous advantages provided by HIPS filler masterbatch improve the efficiency and affordability of plastic products.

3. How to Choose the Right HIPS Filler Masterbatch

Selecting the appropriate HIPS filler masterbatch for your application is crucial for achieving optimal performance and cost-effectiveness. Here are key factors to consider when making your choice:

- Identify application requirements: Take into consideration all the requirements of your application, for example mechanical, impact characteristics, and exposure conditions. This will help you make the right choice of masterbatch that will satisfy these conditions.

- Compatibility with base resin: Make sure that the HIPS filler masterbatch can be used on the base resin that you are currently employing. Consistency influences the production and the quality of the final result of an item.

- Processing conditions: The type of processing and the processing condition also matter; processing temperature and processing techniques are either injection molding or extrusion and the like. Your HIPS filler masterbatch should not deteriorate and create processing problems or even alter when exposed to your particular conditions.

- Supplier considerations: To select the ideal HIPS filler masterbatch, get the service of a reliable supplier with lots of experience. Qualified suppliers are able to assist you in technical matters, give guidance on problem-solving as well as offer solutions according to your preferences.

- Cost considerations: Although cost is a significant element, it should not be implemented with the exclusion of the associated performance gains. Determine the potential long-term advantages of the enhanced properties of the final parts against the costs incurred in applying HIPS filler masterbatch.

Achieving optimal performance and cost-effectiveness in your application requires careful selection of the right HIPS filler masterbatch.

4. Applications of HIPS Filler Masterbatch

HIPS filler masterbatch is a versatile material used across a wide range of industries due to its excellent mechanical properties, cost-effectiveness, and adaptability. Here’s an in-depth look at its applications:

4.1. Packaging

One of the largest consumer industries of HIPS filler masterbatch is the packaging industry. It is widely employed in molding containers, trays, and films for foods and other consumer products.

HIP filler masterbatch has good impact resistance thus ensuring the packaging material provides adequate protection of the contents during transportation and storage. In addition, it also reduces shipping cost due to the ability to reduce lightweight when using HIPS filler masterbatch for the packaging products.

The packaging sector is one of the biggest consumers of HIPS filler masterbatch.

4.2. Consumer electronics

HIPS filler masterbatch is used in the production of casings, housings, and internal structures of consumer electronics items alike to devices including cellular, tablets, and even gaming systems.

The material’s good impact strength further guarantees that electronic devices can readily withstand everyday shocks. Further, the material can be molded to the most complicated shape as required and it comes in different colors, thus it meets consumer appeal.

4.3. Consumer goods

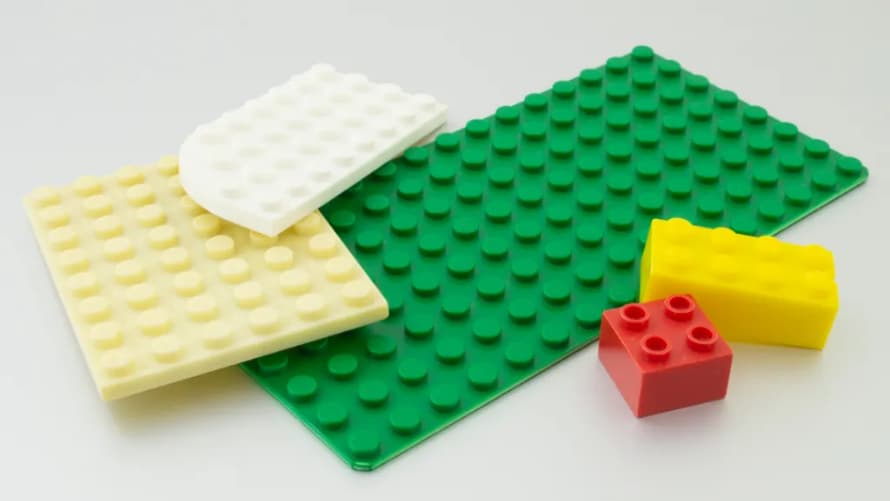

HIPS filler masterbatch is used in numerous consumer goods articles like containers, toys, and small appliances thanks to its strength and flexibility as well as lightweight properties.

For instance, storage containers, there is the HIPS storage container which is not only strong but also light for handling. This application is especially critical in the manufacture of children’s toys since safety and durability remain critical qualities that consumers consider.

HIPS filler masterbatch finds its applications in children’s toys.

4.4. Medical devices

HIPS filler masterbatch is also used in medical applications, involving the usage of medical equipment such as pharmaceutical bottles, pipes, lids of solvent containers.

In addition, medical products made from HIPS filler masterbatch are highly durable and also easy to clean is one of the most crucial factors needed for medical purposes.

4.5. Automotive Components

In automotive application, HIPS Filler Masterbatch is used in your interior and exterior parts of vehicles. It is also appreciated for its high impact resistance and rigidity especially on parts such as dashboards, trims, panels and fuel tanks.

Moreover, when automobiles incorporate lightweight materials from HIPS filler masterbatch, their weight is slightly reduced, meaning improved fuel efficiency.

HIPS filler masterbatch is also applied in automotive fuel tanks.

5. Conclusion

HIPS filler masterbatch presents a versatile solution for manufacturers looking to enhance the properties of plastic products. Understanding its benefits and applications can help businesses make informed decisions in their production processes.

6. Introducing HIPS Filler Masterbatch from EuroPlas

EuroPlas is a leading supplier of high-quality plastic solutions, specializing in advanced masterbatches. Continuously committed to innovation and customer satisfaction, we have become a trusted partner across various industries.

Our superior HIPS filler masterbatch offers outstanding qualities and is a cost-effective solution for plastic manufacturing. Learn more about this product’s features below:

- Save production cost

- Great dispersion, which brings products higher whiteness, transparency, glossiness and smoothness

- High impact strength, which allows to be easily punched, sawed, and cut

- Save energy thanks to CaCO3's great thermal transmission ability

Contact us now for more support!