Cutting plastic can be harder than you thought as the process needs to be done safely with proper tools. Choosing a wrong tool will not give you a clean cut but damage the material. You may get a wavy line or plastic breakage.

However, there are tools and tips to help you become proficient in this job. Let's see how to cut through thick plastic in this article right now!Read more: Plastic cutting tool: A list of most commonly used

1. Useful methods to cut through thick plastic

1.1. Sawing

Thick plastics include Perspex sheeting, plastic skirting, and plastic pipe. The best tool for cutting thick plastic (that is more than 1/4 inch) is a saw. The three best saw types for cutting thick plastic are the table saw, jigsaw, and fine-toothed saw.

A table saw makes the process of cutting of thicker plastic blocks or larger plastic pipes faster. Fine-toothed saws are necessary for precise plastic cutting. Meanwhile, although jigsawing thicker plastic pieces, like piping, may not be perfect, it is a great tool to cut plastic.

If you are using a hacksaw or circular saw, you will need a plastic cutting blade. Large-toothed saws or blades should be avoided as they will cause the plastic to break or crack and leave uneven edges. You will need a saw with a fine-toothed blade in order to cut plastic. Make sure your plastic is fixed to a level surface or work surface before using a hacksaw, jigsaw, or fine-toothed saw to cut it.

Wear eye protection when using a saw to cut plastic, and make sure the material is held in place. Avoid applying too much pressure to prevent melting. And remember to cut slowly after drawing the cut line.

How to cut through hard plastic with different types of saws:

Hacksaw

This tool can be used with just one hand due to its small size and lightweight. It's also a great option because it can melt plastic without using any electricity.

Step 1. Replace and tighten the plastic hacksaw blade to get started.

Step 2. Use clamps to firmly place your plastic on a stable work surface, preventing the material from moving while you're cutting it.

Step 3. Use the dominant hand to grasp the hacksaw and your other hand to move the saw in the right direction.

Step 4. Start with small slices, which due to the slick texture of the plastic may be difficult at first. Next, move the plastic back and forth to cut it.

Jigsaw

It's a quick and simple way to cut hard plastic without breaking it and create no wobble. You'll need a sharp blade and a clamp to hold the plastic in place for heavy-duty plastic cutting.

Step 1. Secure your workpiece with the clamp to start.

Step 2. Pull the trigger to begin the jigsaw. When the saw reaches its maximum speed, use a steady hand to press the blade against the plastic to begin cutting.

1.1.3. Circular saw

Step 1. First, replace the wood-cutting blade with a plastic-cutting circular saw blade.

Step 2. Tightly fasten the plastic sheet after positioning it on a sturdy workbench.

Step 3. After that, plug in the circular saw and wait until it speeds up.

Step 4. Next, proceed cautiously towards the blade. The thick piece of plastic should be slowly compressed until it is completely cut.

The high speed of the blade requires a lot of heat, causing the plastic to melt quickly. Thus, a non-melt blade is needed to prevent melting your material.

Circular saw techniques work better with thin sheets than thick blocks. This is due to the fact that if the plastic is too thick to cut, the circular saw blade will generate excessive heat, melting the material like a hot knife.

1.2. Drilling

An efficient tool for cutting thick plastic is a drilling machine. Cutting hard plastic with this method takes time, but it works well. Your pieces stay together because the holes prevent the remaining plastic from shattering in other areas.

Step 1. Choose a small-size drill bit. Even with a saw or a sharp knife, cutting straight through thick plastic is frequently difficult. It will be easier to cut through plastic if you drill a number of tiny holes in the material you intend to remove. You'll need a power drill and a small drill bit for this. Select a drill bit with a maximum diameter of 1/8 inch (0.32 cm). If you don't have drill bits in different sizes and an electric power drill, you can get them at your neighborhood hardware store.

Step 2. In order to cut through or remove plastic pieces, drill a minimum of six holes in it. Drill six to ten holes with the small drill bit in the plastic section you want to eliminate or cut through. Place these holes near one another as much as possible .The plastic's structure will be weakened as a result.

The best use case for this technique would be fine detail cutting, like on a hobby miniature. Drilling tiny holes all over the surface of the plastic will allow you to cut through very large sections of it. This technique might even be effective for cutting thick PVC pipe. Although it will take a lot of time and effort, the process will enable you to cut with high accuracy.

Step 3. Cut through each hole in turn. Cut through the plastic that is still in between the holes you have drilled using a hobby knife or utility knife. The thick plastic may still be difficult to cut through. Still, the plastic you're cutting through will be weak because a large portion of the connecting material will have been removed.

1.3. Using a string

The least expensive method for cutting through hard plastic is using a string. This might be the most effective way for you to cut thick plastic if you have a lot of free time but are on a tight budget. All you'll need is a spool of cotton or polyester thread and be patient.

Here is how to cut through thick plastic using string:

Step 1. First, you need to check the durability of your string. To cut through plastic, you'll need a section of string that is roughly two feet (61 cm) long. Hold the string and jerk your hands outward with a medium amount of force. It can do the job well if it flexes slightly without breaking.

Step 2. It is necessary to hold the plastic steady as you use the string to cut through it since you'll need both hands free. You could also use a C-clamp to hold the plastic to a worktable, depending on its size and shape. However, it is dangerous because the plastic may shatter if you apply too much pressure to the clamp.

Step 3. To begin a small incision, move the thread back and forth. The best way to do it is to position the thread in a corner or along a plastic edge. You will see a tiny groove appear in the plastic after a short while. After inserting the thread into this small groove, work it back and forth. Eventually, the groove will grow and the cutting process will be done. Note that it is a slow process. Although it can take hours, cutting through thick plastic with thread is an effective method when working with hobby models and miniatures or customizing an RC car.

2. Guideline on how to cut through thick plastic without breaking it

2.1. Use safety measures

Wearing gloves and safety glasses is a must when operating a saw or drilling machine. When working, you can use a vacuum or dust blower to keep your workspace tidy.

2.2. Select the right tools

For cutting thin sheets of polycarbonate and acrylic, or any other hard plastic, you can use a hot knife or a hook knife. A circular saw is your best bet for a high-quality finish on thicker ones. When cutting circles or curves, use a hole saw or jigsaw.

2.3. Move slowly

In addition to keeping the material straight and staying on your intended cutting line, you want to proceed slowly to reduce melting.

2.4. Draw a line before starting

Once you start the process, it is easy to lose sight of where you are cutting. Thus, plan ahead and draw the desired line on the hard plastic piece.

2.5. Avoid excessive pressure

Anybody who has ever cut through thick plastic will tell you to be careful not to apply too much pressure when trying to keep the material in its place. Use just enough pressure when clamping to prevent it from swaying or moving.

3. EuroPlas - A world leader plastic manufacturer

EuroPlas is known as a leader in the masterbatch field since the company satisfies a wide range of requirements for unique plastic raw material solutions to optimize production costs and improve the competitiveness of the customers.

Here is the list of outstanding products from EuroPlas:

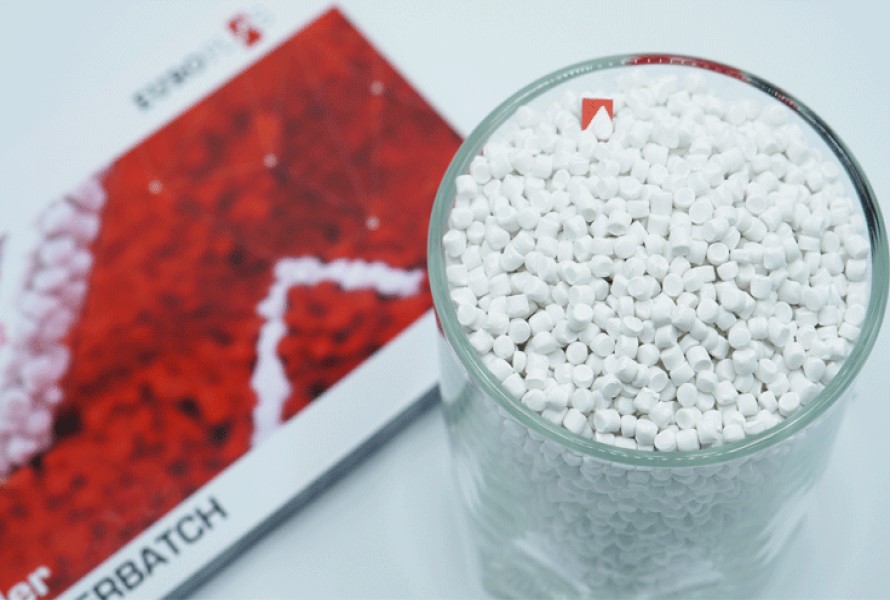

With more than 15 years of producing and exporting filler masterbatch to thousands of businesses around the world, EuroPlas is proud to offer a wide range of filler masterbatch to help manufacturers save cost, enhance productivity and produce high-quality plastic products.

With more than 15 years of producing and exporting filler masterbatch to thousands of businesses around the world, EuroPlas is proud to offer a wide range of filler masterbatch to help manufacturers save cost, enhance productivity and produce high-quality plastic products.

EuroPlas filler masterbatch combines calcium carbonate CaCO3, primary resin, and other plastic additives based on the customers' requirements. The products have many advantages, such as reduced shrinkage, improved stiffness, and bend strength, the capability to enhance stability, printability, and surface quality of the final products, and energy savings. It's ideal for injection molding, blow molding, PVC pipe manufacturing, packaging, plastic frames, door production, etc.

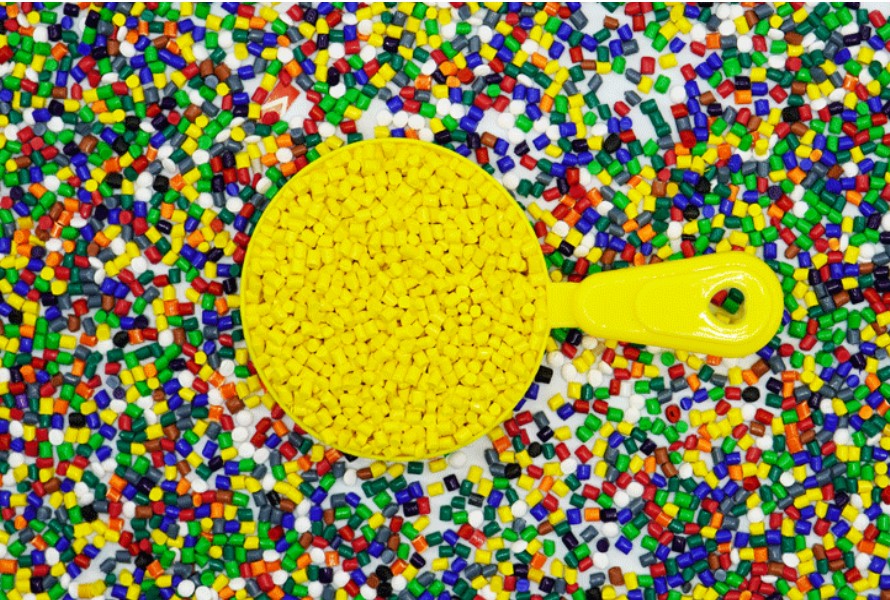

Color masterbatch from EuroPlas is a solution for end-product aesthetics. It's made from high-quality pigments, carrier resin, and some special additives, creating a colorful and attractive appearance. EuroPlas provides a wide range of colors and effects, from simple to complicated, of color masterbatch.

Color masterbatch from EuroPlas is a solution for end-product aesthetics. It's made from high-quality pigments, carrier resin, and some special additives, creating a colorful and attractive appearance. EuroPlas provides a wide range of colors and effects, from simple to complicated, of color masterbatch.

Besides the help to meet color requirements, the material saves time and cost as manufacturers can use it directly in the production process. Plus, it causes no harm to the environment.

Plastic additives are a necessary substance used in the production process to improve the material's performance. Besides, they help the plastic become more durable, thanks to the enhanced chemical and physical resistance.

Plastic additives are a necessary substance used in the production process to improve the material's performance. Besides, they help the plastic become more durable, thanks to the enhanced chemical and physical resistance.

EuroPlas has a wide range of additives for plastic, such as Flame retardants, Desiccants, Odor removing additives, Anti-UV additives, Anti-aging additives, Anti-fog additives, Antistatic additives, Anti-blocking additives, and Processing-aid additives.

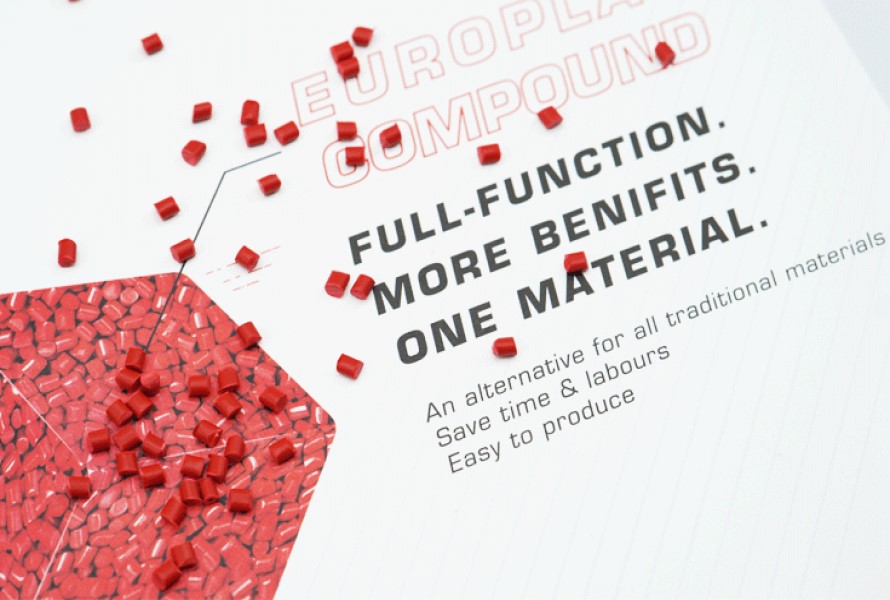

EuroPlas engineering plastic compound is full-function-in-one-material to save time and production costs. The combination is made of resin, additives, and reinforcements (based on the end-product requirements).

EuroPlas engineering plastic compound is full-function-in-one-material to save time and production costs. The combination is made of resin, additives, and reinforcements (based on the end-product requirements).

All EuroPlas products are various, including PA6, PA66 blend compound, PBT GF-FR compound, ABS Glass fiber compound, ABS Antistatic compound, PC flame retardant compound, and ABS. All are of high quality and flexibility. If you're looking for a material for automobile, electronics manufacturing, interior decoration, and renewable energy, you should not miss these products from EuroPlas.

As a professional, EuroPlas understands the industry's ongoing trend and demand for green, biodegradable plastic. And the company is also concerned about sustainable development and the environment; thus, a list of high-quality EuroPlas bioplastic compounds is produced to be used in various aspects, including automotive & transport, construction, fibers, electronics, household appliances, and especially food packaging.

BioNEXT, a bio compound exclusively developed by EuroPlas, can be decomposable within 12 months after use. The company guarantees that the end product passes strict quality control management to meet all the requirements.

Contact EuroPlas right now for the best price of all products!