Due to its amazing qualities, carbon black is a fantastic material that can be acquired and utilized in a variety of goods and applications. The last thing you want to happen while buying, storing, and transporting carbon black particles for your next project is to lose them. But because of the design of many baffle bags and the tiny size of carbon black particles, that is exactly what might happen. To help you understand more about this incredible material, we're going to look at how to measure the carbon black particle size and more useful information about carbon black masterbatch in today's article.

Related:

- 10 black masterbatch suppliers you should know

- Black masterbatch market report (estimated to 2030)

- EuroPlas black masterbatch and our standardized production procedure

- Black masterbatch: facts you may surprise

I. How to measure the particle size of carbon black

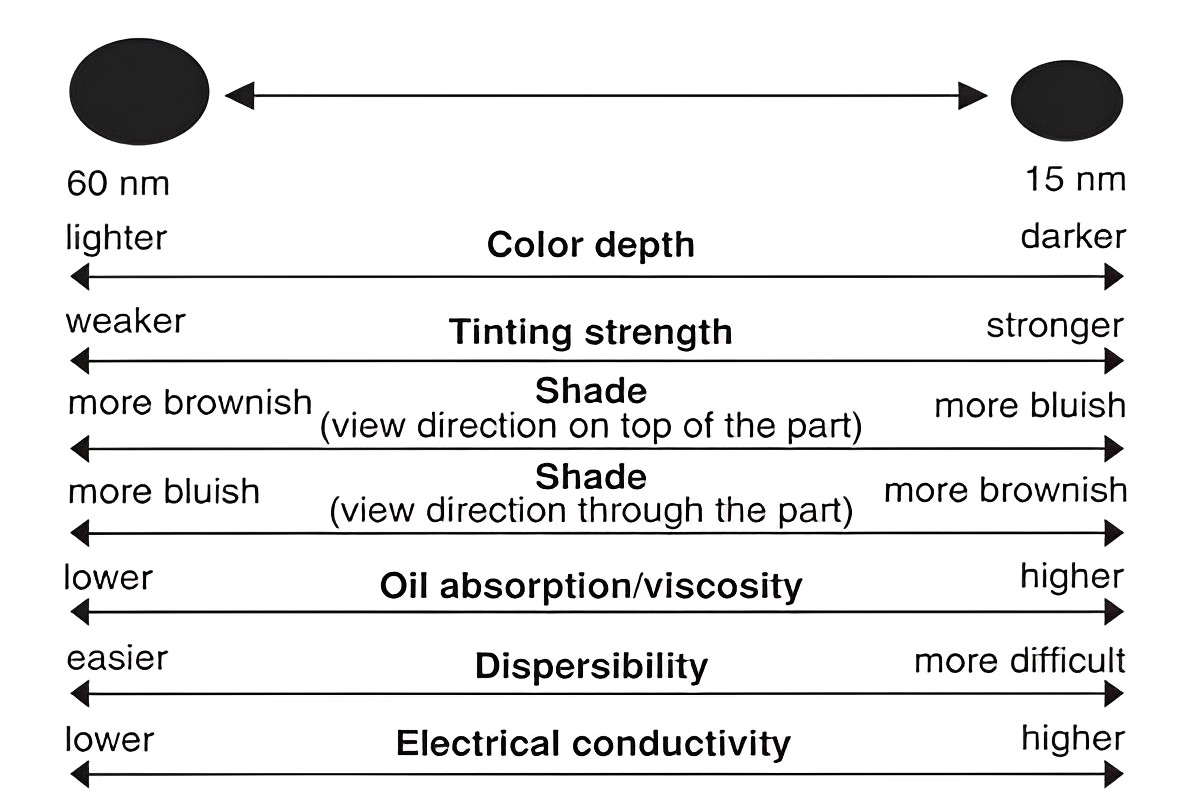

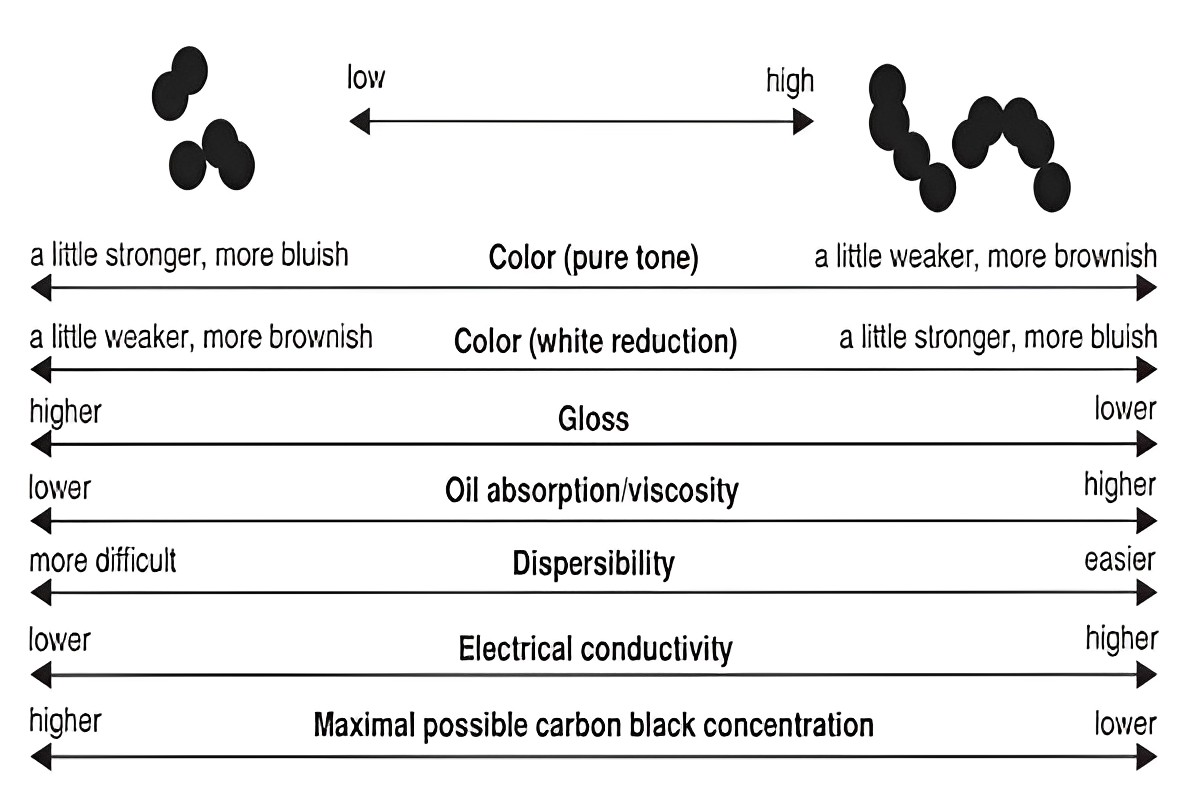

Carbon black refers to finely separated carbon in general. Carbon black is created when petroleum fuel is incompletely burned. The composition of carbon black particles may be determined under magnification. The size of the main particles is measured in nanometers (nm).

Through van der Waals interactions, the main particles unite to form tightly bonded clusters known as aggregates. The size and form of the aggregate define the structure of the carbon black. A highly structured carbon black is made up of several carbon black particles that have been joined into a multi-branched aggregate. Agglomerates are formed when aggregates join together loosely.

The size of the particles has a direct impact on their performance. In the plastics industry, particle sizes ranging from 14nm to 90nm are often utilized.

Carbon black has several applications that vary due to particle size. As a result, knowing the structure, porosity, physical shape, and particle size is critical since these characteristics impact a product's performance.

Because carbon black particles are so minute, identifying individual particles from a big group can be challenging with the naked eye. There are two typical ways of measurement:

- Laser diffraction: A laser emits a beam of light, which the particles scatter. By calculating the scattering angle, the particle size is determined.

- Dynamic light scattering: Liquid suspension of carbon black particles. The size of the particles in suspension is determined by calculating the intensity and angle of the light dispersed from the light source.

II. Carbon black masterbatch - an amazing product from carbon black

1. Definition

Carbon black masterbatch, also known as black masterbatch is a granular mixture of black carbon pigment, virgin resin, and specialized additives. Those components, along with their proportions, will be altered and tailored based on the end needs of the final product, ensuring that it precisely meets consumers' expectations.

2. Benefits

Excellent dispersion: The greatest advantage of color masterbatch is unquestionably its dispersion. Color masterbatch, unlike pigments, disperses more uniformly on the product surface because it contains resin that has previously been utilized in final goods, improving color fastness.

Enhancement of properties: Carbon black masterbatch lets manufacturers add other additives for additional functionality such as UV resistance,... As a result, it considerably enhances the overall mechanical qualities of the end product.

Affordability: This is unquestionably a benefit of color masterbatch over engineering plastic compounds. Despite the fact that they are both in masterbatch form, compounds are significantly more expensive due to their sophisticated production procedure. Carbon black masterbatch, on the other hand, is straightforward to create in large quantities, making it the best alternative for coloring processes.

III. Types of carbon black masterbatch

There are many types of different of carbon black masterbatch. Each offers great attributes to suit a range of different requirements. Here are some types of carbon black masterbatch that you should consider.

PET carbon black masterbatch

PET carbon black masterbatch is one of the most common types of carbon black masterbatch. PET carbon black resin may fulfill the color requirements of customer's plastic products because of its heat resistance, excellent movement resistance, bright color, uniform color, good dispersion, and little color difference.

PET carbon black plastic pellets are environmentally friendly and nevertheless enable the creation of a range of hues to satisfy consumer demands.

PP carbon black masterbatch

Polypropylene, a polymer with exceptional mechanical strength, is referred to as PP plastic. Products made of PP carbon black plastic is frequently used because they have a nice surface gloss, are waterproof, have good air permeability, and are not quickly oxidized or damaged by other gases, steam, or grease.

PE carbon black masterbatch

Having a changeable crystalline structure, PE resin is a type of flexible plastic granule. Waterproof, anti-conductive, and anti-thermal are a few examples of distinguishing qualities. Due to its affordability, flexibility, lightweight, and durability, PE carbon black plastic is widely used in a wide range of goods and sectors.

PBT carbon black masterbatch

The semi-crystalline thermoplastic polybutylene terephthalate, often known as PBT resin, belongs to the family of polyester polymers. PBT carbon black masterbatch are especially well suited for uses in the food sector because of their excellent resistance to cleaning agents like chlorine and caustic solutions.

PBT carbon black masterbatch also exhibits great stiffness, strength, and thermal deformation resistance, extremely good dimensional stability and low tendencies.

We also provide other types of carbon black masterbatch depending on the customer's requirements. The products are provided in different colors and sizes to meet different customers' needs. If you are interested in our products and services, please contact us today!

IV. Uses for carbon black masterbatch

Having so many great properties, carbon black masterbatch is utilized in many aspects and industries. But what is carbon black used for in detail? Here are the applications of carbon black.

Carbon black masterbatch for agriculture

The cultivation, harvesting, and processing of agricultural goods need the use of black plastic sheets, rods, tubing, and films. Plastics made from carbon black masterbatch are also used in equipment and machinery for bins, chutes, liners, and hoppers. Because of the usage of these items, crops may even be planted in arid areas and cultivated throughout the year, the temperature can be controlled, and insects cannot damage the crops.

Carbon black masterbatch for geosynthetics

Geosynthetics is also one of the common uses for carbon black masterbatch. They are commonly used in the construction sector for environmental engineering, geotechnical applications, and water containment. They can be used for sealing, as a barrier layer, filtration, drainage, strengthening, and protection.

Carbon black masterbatch for automotive

Plastics made from carbon black masterbatch are increasingly being utilized in the automobile industry to save weight and cut costs, in conjunction with accurate optical concepts, tight tolerances, and a high degree of striving for originality, creativity, and performance. As a result, uses for carbon black are ideal for producing high-quality plastic components for automobiles.

Carbon black masterbatch for non-woven fabric

One of the most flexible materials on the market right now is non-woven fabric. Today's modern technologies ensure that non-woven fabrics are developed to satisfy the demanding performance requirements of the many applications used by our clients, in contrast to other fabrics and substrates that are manufactured by knitting, weaving, or other methods.

Non-woven fabrics offer greater value than more conventional materials and are dynamic. Fabrics may be created with nonwoven technology to have a variety of properties (superior strength, consistency,..) that other materials just cannot match.

Carbon black masterbatch for extrusion

Extrusion is also employed in the production of plastic made from carbon black masterbatch. Because the technique is utilized to produce large quantities of a desired product, it is in great demand for the production of appliance components and packaging. The extrusion method enhances the stiffness and bearing capacity of end items by using carbon black masterbatch.

V. Carbon black masterbatch supplier

Europlas, a leading manufacturer of carbon black masterbatch in Vietnam, is working with many domestic and international clients to provide them with high-quality carbon black masterbatch.

We have over 15 years' experience in the industry and we have exported our products to many countries around the world. We have a very good reputation in this field, which is why we are one of the best carbon black masterbatch suppliers in Vietnam.

We also provide customized solutions for you based on your needs. Our experts will be happy to help you develop your own.

Source: Abbey Vietnam

Abbey Vietnam is another high-quality black masterbatch supplier. Abbey Vietnam has a professional team that can offer you reliable products at competitive prices. They have been supplying carbon black masterbatch to various industries such as pharmaceutical, food, and cosmetics for many years. Their expertise lies in producing high-quality carbon black masterbatch for various types of industries.

Source: Polyfill

Polyfill is a leading manufacturer of high-performance masterbatch and additive solutions for the plastics industry. Their product line includes a wide range of polyurethane, polyester, and epoxy resin products, which can be used as fillers or extenders in many applications.

Polyfill has been supplying high-quality industrial polyurethane and polyester products to customers in the automotive, consumer electronics, medical equipment, furniture, packaging, and building industries.

Source: Fillplas

Fillplas is one of the top carbon black masterbatch suppliers. They produce a wide range of products, including food additives, pharmaceuticals, and personal care products. They can offer you any product within our range that suits your application. Fillplas carbon black masterbatch products are available in different grades, sizes, and specifications to meet your specific requirements.

Source: Cabot

Cabot is the final black masterbatch supplier on this list. As one of the top masterbatch manufacturers, they are a fully integrated supplier of specialty chemicals, ingredients, and additives for many industries including automotive, electronics, and aerospace.

Their core business is to provide high-quality, consistent, and reliable products that enhance product performance for our customers. We have experience working with a number of industries and provide masterbatches that are suitable for use in a wide range of products, including cosmetics, pharmaceuticals, and food additives.