PBAT plastic (Polybutylene Adipate Terephthalate) is revolutionizing sustainable materials. Amid growing concerns about plastic waste, PBAT stands out as a biodegradable, flexible, and durable polymer that decomposes into non-toxic substances.This article explores PBAT's unique properties, environmental benefits, and versatile applications in packaging, agriculture, and medical technology. It also highlights advancements and challenges as PBAT gains global traction.Discover how EuroPlas is innovating in bioplastics with high-quality PBAT products, helping reduce plastic pollution and advancing the circular economy. PBAT plastic is shaping the future of compostable materials.

1. Overview of PBAT Plastic

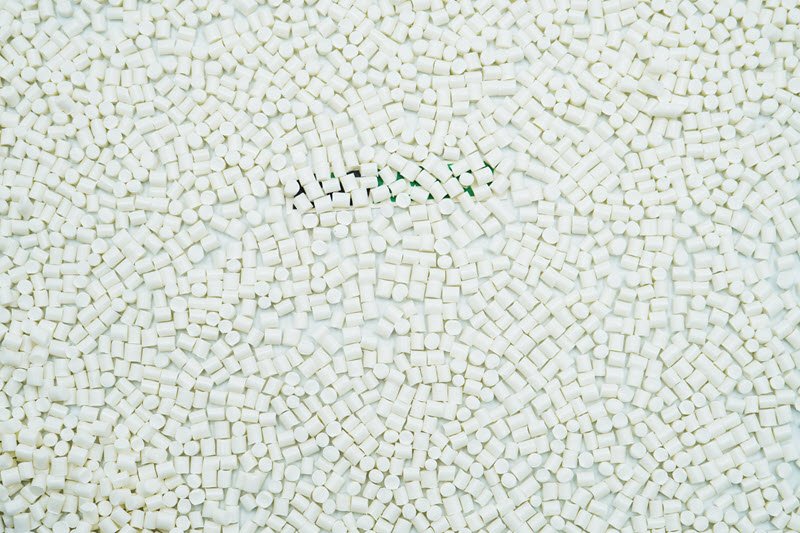

PBAT (Polybutylene Adipate Terephthalate) is a remarkable biodegradable and compostable thermoplastic polymer that has gained attention as a key player in the shift toward sustainable materials. Known for its flexibility, durability, and ease of processing, PBAT is a material that bridges the gap between functionality and eco-friendliness. It combines the mechanical strength of traditional plastics with the distinct advantage of biodegradability, offering a versatile solution for a range of applications, from packaging to agriculture.

PBAT (Polybutylene Adipate Terephthalate) is a remarkable biodegradable and compostable thermoplastic polymer.

PBAT is synthesized from fossil fuels, but unlike conventional plastics, it is engineered to break down naturally under industrial composting conditions. Through microbial activity, PBAT decomposes into water, carbon dioxide, and biomass, leaving no toxic residues behind. This property positions PBAT as an environmentally responsible alternative for industries seeking to reduce their ecological footprint while maintaining product performance.

Read more: What is PBAT plastic? Pros and cons of PBAT

Moreover, PBAT’s adaptability allows it to be blended with other bioplastics, such as PLA or starch-based polymers, further enhancing its properties. This makes it suitable for applications where strength, flexibility, and biodegradability are all critical requirements. As the demand for sustainable materials continues to rise, PBAT stands out as a promising candidate in the movement toward a circular economy and the fight against plastic pollution.

2. Why PBAT Plastic is Considered Compostable

The compostability of PBAT stems from its unique chemical structure, which allows it to break down rapidly and efficiently in the presence of microorganisms, heat, and moisture. Unlike traditional plastics that persist in the environment for hundreds of years, PBAT undergoes microbial degradation, turning into water, carbon dioxide, and biomass without leaving any harmful residues. This rapid decomposition process typically takes a few weeks under industrial composting conditions, making PBAT a standout material in the movement toward reducing plastic waste.

The compostability of PBAT stems from its unique chemical structure.

The compostability of PBAT stems from its unique chemical structure.

What sets PBAT apart is its ability to balance functionality with eco-friendliness. It maintains the strength, flexibility, and durability required for practical applications while ensuring that its environmental impact is minimal after disposal. This dual advantage makes PBAT an ideal material for various products, such as compostable shopping bags, single-use food packaging, disposable cutlery, and even agricultural films. These items not only serve their intended purpose effectively but also contribute to waste management systems by being compatible with composting facilities.

In addition, PBAT can be combined with other bioplastics like PLA (polylactic acid) or starch-based polymers to enhance its properties. This blending allows manufacturers to create customized materials tailored to specific needs, whether for stronger packaging films or more durable agricultural products. As a result, PBAT is increasingly being adopted in industries where sustainability and performance go hand in hand, meeting consumer demands for eco-friendly alternatives without compromising on quality or usability.

With the growing focus on reducing plastic pollution and shifting toward a circular economy, PBAT has emerged as a leading solution in compostable materials. Its potential to replace conventional plastics in key applications positions it as a critical material in addressing global environmental challenges and fostering a sustainable future.

3. Applications of PBAT in Compostable Materials

PBAT plastic is renowned for its versatility, making it an ideal material across a wide range of industries that prioritize both functionality and environmental responsibility. Its unique properties, such as flexibility, durability, and full biodegradability, have opened up diverse avenues for its use, including:

3.1.Packaging Solutions

One of the most prominent applications of PBAT plastic is in the production of compostable packaging materials. It is frequently used to manufacture compostable shopping bags, trash bags, and food packaging films that maintain high performance while being fully biodegradable. These products ensure effective protection and usability during their lifecycle and leave no lasting impact on the environment after disposal.

PBAT plastic is in the production of compostable packaging materials.

3.2. Agricultural Applications

In the agriculture sector, PBAT plays a pivotal role in creating biodegradable mulch films. These films are essential for controlling weeds, retaining soil moisture, and optimizing crop yields. Unlike traditional plastic films, PBAT-based mulch films degrade naturally into the soil, eliminating the need for costly removal and disposal processes. This feature makes PBAT a sustainable solution for reducing agricultural waste while improving operational efficiency.

3.3. Medical and Hygiene Products

PBAT’s compostable nature has found a valuable application in the medical and hygiene industries. It is used in the production of disposable medical items such as gloves, protective coverings, and sanitary products. These items, often discarded after single use, can be safely composted without contributing to landfill waste, offering a greener alternative to conventional medical-grade plastics.

PBAT’s compostable nature has found a valuable application in the medical and hygiene industries.

3.4. 3D Printing Innovations

As sustainability becomes a priority in manufacturing, PBAT has gained traction in the field of 3D printing. It is increasingly utilized as a base material for eco-friendly 3D printing filaments. These filaments deliver high performance for creating durable, flexible prototypes while ensuring they are environmentally friendly, making PBAT a favorite among designers and engineers looking for sustainable printing solutions.

3.5. Consumer Goods and Household Items

PBAT is also making inroads in the production of everyday consumer goods, including compostable utensils, straws, and food storage containers. These products combine functionality with sustainability, catering to growing consumer demand for greener alternatives in daily life.

3.6. Industrial Applications

Beyond consumer and agricultural uses, PBAT is being explored for industrial applications such as protective films, biodegradable adhesives, and coatings. Its unique combination of mechanical strength and eco-friendly properties makes it a valuable material for specialized use cases where durability and sustainability are equally important.

As industries worldwide increasingly adopt sustainable practices, PBAT's applications continue to expand. From revolutionizing waste management in packaging and agriculture to driving innovation in medical and industrial products, PBAT plastic stands out as a versatile material that supports a circular economy while meeting modern performance demands.

4. Future Outlook for PBAT Plastic

As global demand for sustainable materials continues to grow, PBAT plastic is emerging as a game-changing solution in the fight against plastic pollution. Its potential to replace conventional, non-biodegradable plastics across various sectors underscores its importance in building a more sustainable future. Advances in PBAT production technology are focused on improving its properties, such as flexibility, strength, and biodegradability, while simultaneously reducing manufacturing costs. This approach aims to make PBAT more competitive and accessible to industries worldwide.

Furthermore, ongoing research and development are exploring ways to enhance PBAT’s composting capabilities, ensuring that it performs even better in industrial and home composting environments. Governments and organizations around the globe are also implementing policies and incentives to promote biodegradable materials like PBAT, encouraging businesses to adopt greener alternatives in their supply chains.

As awareness of environmental issues grows among consumers, the demand for compostable products is set to rise, driving innovation and investment in PBAT-based solutions. From revolutionizing packaging and agriculture to enabling sustainable advances in technology and consumer goods, PBAT holds the potential to transform industries, reduce waste, and support the transition to a circular economy. If these efforts continue at the current pace, PBAT plastic could become a cornerstone of sustainable development, setting a new standard for environmentally friendly materials.

5. Conclusion

PBAT plastic provides a sustainable solution to the environmental challenges caused by conventional plastics like polyethylene and polypropylene, which persist for centuries, harming ecosystems and wildlife. As the world seeks eco-friendly alternatives, PBAT (Polybutylene adipate terephthalate) stands out for its compostability, versatility, and innovation potential.

PBAT is biodegradable, breaking down into water, carbon dioxide, and biomass under composting conditions, significantly reducing its impact on landfills and oceans. Made from renewable resources, it offers an eco-friendly alternative for industries striving to minimize plastic pollution.

Its versatility enables its use in packaging, agricultural films, disposable items, and textiles. PBAT blends well with other biodegradable polymers, enhancing its strength, flexibility, and moisture resistance, making it suitable for products like single-use bags, food packaging, and gardening supplies.

Research continues to improve PBAT’s properties, such as durability and thermal stability, while maintaining cost-effectiveness. Rising demand for compostable materials and regulatory support are further driving its adoption, positioning PBAT as a critical player in sustainable materials.

Switching to PBAT allows industries to reduce their environmental footprint, comply with stricter plastic waste regulations, and contribute to a circular economy. With its eco-friendly advantages and ongoing advancements, PBAT is set to play a vital role in the global transition to biodegradable plastics and a cleaner, greener future.

PBAT (Polybutylene adipate terephthalate) is designed to break down under natural conditions.

6. About EuroPlas’ Bioplastics

EuroPlas is a leading provider of innovative bioplastic solutions, offering a wide range of biodegradable and compostable materials, including PBAT, PLA, and PHA-based products. By leveraging renewable resources such as corn, potatoes, and palm oil, as well as advanced polymer technologies, EuroPlas ensures that our bioplastics deliver exceptional performance while contributing to a sustainable future.

Our bioplastic compounds, such as the BiONext series, are designed to decompose naturally into water, CO₂, and biomass within 12 months, creating a circular life cycle that minimizes environmental impact. These materials meet the highest standards of biodegradability and are ideal for various applications, including packaging, agricultural films, food containers, and disposable utensils.

In addition to their eco-friendly properties, EuroPlas’ bioplastics stand out for their excellent mechanical and aesthetic qualities. From high impact strength and flexibility to a glossy finish and ease of processing, our bioplastics meet both functional and aesthetic requirements, making them a versatile solution for industries seeking sustainable alternatives.

At EuroPlas, sustainability is at the core of everything we do. Our commitment to reducing dependence on fossil fuels and promoting environmentally friendly materials aligns with global efforts toward sustainable development. By continuously innovating and adhering to strict quality standards, we empower our partners to transition to greener production methods and contribute to a cleaner planet.

Contact EuroPlas

Discover the full range of bioplastic solutions offered by EuroPlas and learn how we can help you embrace sustainability. Visit our website or connect with our expert team today to start building a greener future!