PBAT, or Polybutylene Adipate Terephthalate, is a type of biodegradable and compostable plastic that is gaining popularity as an eco-friendly solution to the problem of plastic waste. PBAT is made from renewable resources, such as corn starch and sugarcane, and can break down naturally in the environment. In this article, we will explore the pros and cons of PBAT plastic and its applications. Whether you're looking to use this material in your business or just want to learn more about it, this article provides valuable information that you can use to make informed decisions.

Related:

- What are some of the advantages and disadvantages of bioplastics

- What are bioplastic compounds? Outstanding benefits and applications

- Bioplastics - The arduous revolution of the plastic industry

- PLA masterbatch - the future of the plastic industry

- How PHA Bioplastic Differs from PLA and PBAT

- A List of PBAT Resin Innovations You Should Know

- Is PBAT Plastic the Future of Compostable Materials?

1. What is PBAT plastic?

1.1. What is PBAT?

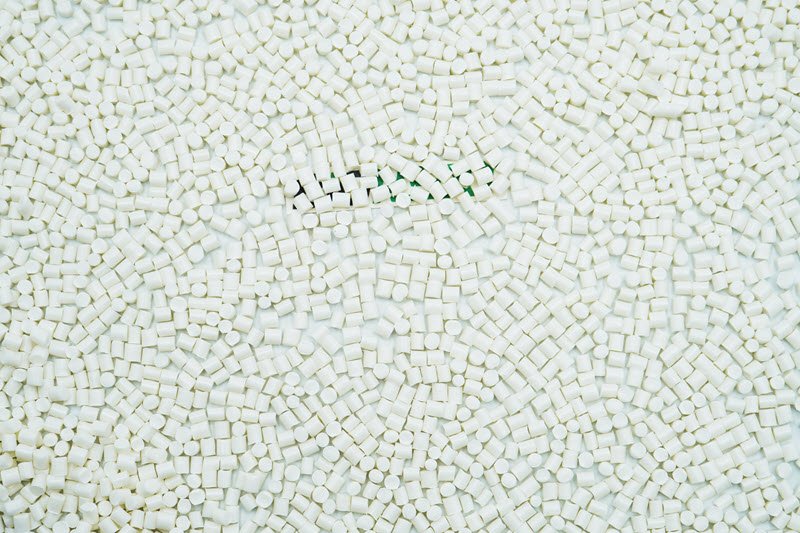

What is PBAT plastic?

PBAT plastic (Polybutylene Adipate Terephthalate) is a biodegradable thermoplastic material synthesized from adipic acid and butylene glycol, combined with terephthalic acid—a component commonly found in PET plastic. This composition gives PBAT both flexibility and mechanical strength while enabling it to decompose in the natural environment through microbial activity.

Unlike some other biodegradable plastics that are brittle or difficult to process, PBAT plastic stands out due to its flexibility and ease of processing. That’s why it is increasingly used in eco-friendly products such as biodegradable garbage bags, food packaging, agricultural mulch films, and cling wraps.

PBAT polymer can be processed using conventional plastic processing techniques and can be blended with other biodegradable polymers to improve its properties. The use of PBAT in packaging and consumer goods is expected to continue to grow as consumers and businesses look for more sustainable solutions.

Read more: PBAT Polymer: Trends and opportunities in 2025

1.2. Applications of PBAT plastic

PBAT plastic has a wide range of applications due to its unique properties and eco-friendly nature. Some of the most common applications of PBAT polymer include:

- Compostable food packaging: PBAT's flexibility and moisture resistance make it ideal for packaging food items, such as fruit and vegetable bags, snack packaging, and cereal boxes. Its ability to provide a good barrier against gases and liquids helps extend the shelf life of food products.

- Compostable agriculture films: PBAT's toughness and resistance to moisture make it suitable for use in agriculture films, such as mulch films, greenhouse films, and silage covers.

- Compostable biodegradable shopping bags: PBAT can be used to manufacture biodegradable shopping bags, which can help reduce the amount of plastic waste in the environment.

- Compostable home and personal care products: PBAT can be used to manufacture a variety of home and personal care products, such as shampoo bottles, soap containers, and toothbrushes.

Applications of PBAT plastic

- Medical products: PBAT can be used in the manufacture of medical products such as suture materials, wound dressings, and other medical devices.

Overall, the versatility and eco-friendly nature of PBAT polymer make it a promising alternative to traditional petroleum-based plastics, and its use is expected to continue to grow as consumers and businesses seek more sustainable solutions.

Read more: What Are The Effects Of PBAT Plastic?

2. Technical characteristics of PBAT plastic

PBAT plastic combines the softness of PBS (polybutylene succinate) with the tensile strength of PET. Key physical properties of PBAT include:

- Tensile strength: 10–35 MPa, suitable for thin films and flexible packaging.

- Elongation at break: often exceeds 400%, indicating strong ductility.

- Melting point: around 110–120°C.

- Biodegradability: fully decomposes in industrial composting environments within 90 to 180 days and can degrade faster in moist soil conditions.

3. Advantages and disadvantages of PBAT plastic

This section will provide an overview of the advantages and disadvantages of PBAT, helping you make an informed decision about whether it's the right choice for your needs.

3.1. Advantages of PBAT plastic:

- Biodegradability and compostability: PBAT is biodegradable and compostable, meaning it can be broken down into its constituent parts by microorganisms in the environment. This helps to reduce its impact on the ecosystem and minimizes plastic waste.

- Renewable resources: PBAT is made from renewable resources such as sugar cane and corn starch, reducing its reliance on non-renewable petroleum-based resources.

- Versatile: PBAT is flexible and tough, making it suitable for a wide range of applications such as food packaging, agriculture films, and biodegradable shopping bags.

- Good barrier properties: PBAT provides a good barrier against gases and liquids, helping to extend the shelf life of packaged goods and maintain the freshness of food items.

3.2. Disadvantages of PBAT plastic:

- Cost: PBAT is more expensive to produce compared to traditional petroleum-based plastics, which can make it more expensive for consumers.

- Limited industrial use: PBAT is not as widely used in the industry compared to traditional plastics, which may limit its availability and make it harder to find a suitable solution for some applications.

- Environmental impact: Although PBAT is biodegradable and compostable, it still has an impact on the environment if not disposed of properly. The composting process also requires specific conditions to break down the material effectively.

- Performance limitations: PBAT has some performance limitations compared to traditional petroleum-based plastics, such as a lower melting temperature and reduced resistance to UV light and heat.

4. PBAT vs PLA: What is the difference?

PBAT (Polybutylene Adipate Terephthalate) and PLA (Polylactic Acid) are both biodegradable and compostable plastics that are gaining popularity as alternatives to traditional petroleum-based plastics. However, they have some key differences that set them apart from each other.

- Composition: PBAT is a copolymer made from a combination of polybutylene adipate and polyethylene terephthalate, while PLA is made from lactic acid, which is derived from corn starch, sugarcane, or other renewable resources.

- Performance: PBAT is flexible and tough, making it suitable for a wide range of applications such as food packaging and biodegradable shopping bags. On the other hand, PLA is rigid and brittle, making it more suitable for applications where stiffness and dimensional stability are important, such as cutlery, drinking straws, and packaging for electronics.

- Biodegradability and compostability: Both PBAT and PLA are biodegradable and compostable, but PBAT has a faster degradation rate compared to PLA, meaning it will break down more quickly in the environment.

- Cost: PBAT is more expensive to produce compared to traditional petroleum-based plastics, while PLA is typically more expensive compared to PBAT.

Read more: PBAT vs. PLA: How To Know The Right Plastic?

In conclusion, both PBAT vs PLA have their own unique advantages and disadvantages and the choice between them will depend on the specific requirements of the application. It is important to carefully evaluate the trade-offs between performance, cost, and environmental impact when making a decision.

5. Finding a reliable PBAT plastic supplier?

As environmental concerns grow, more and more companies are looking for eco-friendly and sustainable alternatives to traditional plastics. In this pursuit, PBAT (polybutylene adipate-co-terephthalate) plastic has emerged as a promising option.

For those looking to incorporate PBAT plastic into their products, finding a reliable supplier is crucial. In this regard, EuroPlas is a top masterbatch manufacturer in Vietnam, offering a wide range of bioproducts to meet the needs of various industries. EuroPlas offers two bioproducts, the BiONext bio-compound, and the BiOMates bio filler.

Finding a reliable PBAT plastic supplier?

- Components: BiONext is a combination of bioplastic and other components such as reinforced CaCO3 powder, modified starch powder, specific plasticizers, talc, and specific additives. This unique composition of components offers a range of useful characteristics.

- Characteristics: The biodegradable nature of BiONext makes it an environmentally friendly choice, breaking down within 12 months after use. Its full function in one material allows it to be directly processed without the need for additional materials. BiONext boasts high stiffness, low melt flow index, high impact strength, and ease of processing, making it an ideal material for a range of applications. It also has the ability to keep moisture on the surface, resulting in longer food preservation.

- Applications: BiONext is ideal for a variety of applications such as food packaging, biodegradable shopping bags, and other packaging materials. Its durability and sustainability make it a preferred choice for businesses looking to reduce their environmental footprint.

- Product Codes: BiONext is available in a range of product codes including 102, 152, 400, 500, 600, and 700. Each product code offers different properties and performance characteristics, making it easy to find the right BiONext product for your specific needs.

Find out the products at: Bio compound - BiONext

Read more: BiONext - the inevitable innovation of the industry

Finding a reliable PBAT plastic supplier?

- Components: BiOMates, a bio filler produced by EuroPlas, is a crucial component in the creation of biodegradable products. It is made of a mixture of bio-resin and modified components, such as CaCO3, BaSO4, talc, along with dispersion additives. The result is a material that provides added strength and durability to biodegradable products.

- Characteristics: The characteristics of BiOMates include its biodegradability, making it an environmentally friendly choice for various applications. In addition, it offers a cost-effective solution, as it can be used in conjunction with other bio-based resins.

- Applications: The applications of BiOMates are diverse, including biodegradable film, dental picks and floss, straws, thermoformed trays, single-use utensils, shopping bags, food packaging film, rolling film, and mulch film.

- Product Codes: To purchase BiOMates, customers can choose from product codes 01, 02, and 03. Each product code offers different properties and performance characteristics, making it easy to find the right BiOMates product for your specific needs.

Find out the products at: Biofiller - BiOMates

Read more: BiOMates – EuroPlas filler masterbatch that is friendly to the environment

Overall, these bioproducts from EuroPlas are designed to meet the growing demand for environmentally-friendly products. With over 15 years of experience in the industry, EuroPlas has established a reputation for producing high-quality products and providing excellent customer service.

For more information about EuroPlas and our bioproducts, please do not hesitate to contact us. Our team is always available to answer any questions you may have and help you find the best solution for your needs. So why wait? Take the first step towards a more sustainable future today by choosing EuroPlas as your PBAT plastic supplier.