In the world of modern materials, nylon stands out as one of the most adaptable and widely used synthetic polymers. Since its invention in the 1930s, nylon has transformed the way we produce clothing, automotive parts, consumer goods, and even industrial equipment. But like any material, it comes with both benefits and trade-offs. Understanding nylon's advantages and disadvantages is essential for making informed decisions—whether you're in product design, manufacturing, or just trying to choose the right jacket.

Let’s take a closer look at what nylon is, where it’s used, and what you need to know about its strengths and weaknesses.

Related:

- 25+ facts about recycling plastic bags

- The effects of plastic bags on the environment - how to alleviate this problem

- Plastic and Non Woven Shopping Bags: Real “Green” Bags

1. What is nylon? How is nylon made?

1.1. Definition and origin

Nylon is a synthetic thermoplastic polymer belonging to the polyamide family. It was first developed in 1935 by Wallace Carothers, a chemist working for DuPont. Originally intended as a substitute for silk in stockings, nylon rapidly gained traction in a variety of industries thanks to its durability, stretchability, and low cost.

Today, nylon is one of the most popular engineering plastics used in textiles, automotive parts, electrical insulation, medical devices, and more. Unlike natural fibers such as cotton or wool, nylon is entirely man-made from petrochemicals—primarily from compounds like hexamethylenediamine and adipic acid.

1.2. Common types of nylon

Several types of nylon exist, but the most commonly used include:

- Nylon 6: Made through ring-opening polymerization of caprolactam, offering good toughness and chemical resistance.

- Nylon 6,6: Created by combining hexamethylenediamine with adipic acid, known for its higher melting point and mechanical strength.

- Other variants: Nylon 11, nylon 12, and reinforced grades (e.g., glass-filled nylon) are used for more specialized applications.

Read more: What is nylon? All about its properties and common uses

2. Nylon advantages and disadvantages

2.1. Nylon advantages

Nylon has several advantages that make it a popular choice in many different applications:

- Strength: Nylon has excellent tensile strength, making it ideal for use in applications such as ropes, gears, and machinery parts. It is also highly resistant to abrasion, suitable for applications where wear and tear are a concern.

- Versatility: Nylon can be produced in a variety of forms, including fibers, films, and moldings. It can also be easily colored, making it a good choice for products that require color consistency, such as clothing and textiles.

- Durability: Nylon is highly resistant to wear and tear, a good choice for products that will be used frequently and for long periods of time. This property is also ideal for applications that require high durability, such as gears, ropes, and backpacks.

- Moisture Resistance: Nylon is highly resistant to moisture. Thus, it is used to manufacture products that will be exposed to water or other liquids, such as outdoor gear and clothing or applications where hygiene is a concern, such as medical devices and packaging.

- Chemical Resistance: Nylon is resistant to many chemicals, including acids and bases. The applications of this property is laboratory equipment and industrial products.

- Lightweight: Nylon is a lightweight material that can be applied to produced gear, ropes, and backpacks applications where weight reduction is important, such as aircraft and automotive parts.

- Easy to process: Nylon is easy to process and can be molded into complex shapes and designs. Therefore, it is a cost-effective solution, as it reduces the need for secondary machining or assembly processes.

2.2. Nylon disadvantages

However, Nylon has some disadvantages that may limit its use in certain applications or make it less desirable than other materials:

- Cost: Nylon can be more expensive than other synthetic materials such as acetate, qcrylic, lyocell, microfibre, etc.

- Hydrolysis: Nylon is susceptible to hydrolysis, a chemical reaction that causes the material to break down in the presence of moisture. This can reduce the strength and durability of nylon over time, making it less suitable for long-term applications or applications in moist environments.

- UV sensitivity: Nylon is sensitive to ultraviolet light and can degrade over time when exposed to sunlight, making it less suitable for outdoor applications.

- Limited temperature resistance: Nylon has a limited temperature resistance and can deform or lose strength at high temperatures. So, is not a good choice for high-heat applications such as electrical insulation.

- Flammability: Nylon is a flammable material and can ignite easily fire safety, consider other proper materials.

- Environmental impact: Nylon production is energy-intensive and can have a negative impact on the environment, as well as contribute to the accumulation of plastic waste in the natural environment.

In short, while nylon has several advantages, it also has some limitations that should be taken into consideration. The cost, susceptibility to hydrolysis, sensitivity to UV light, limited temperature resistance, flammability, and environmental impact of nylon production are all factors that should be considered before choosing it for a particular use.

3. 10 Common Questions About Nylon – Answered

3.1. Is nylon waterproof?

Nylon is water-resistant but not fully waterproof. It can repel light moisture, which is why it's used in windbreakers and backpacks. However, with prolonged exposure or submersion, nylon will absorb water, making it unsuitable for completely watertight applications without coatings.

3.2. Is nylon breathable?

Not inherently. Nylon's tight molecular structure doesn’t allow air to pass through easily. For this reason, pure nylon fabrics can trap heat and moisture. However, breathability can be enhanced through mesh designs or fabric blends—making it more comfortable in apparel like sportswear.

3.3. Is nylon natural or synthetic?

Nylon is a fully synthetic polymer created from petrochemical compounds. It doesn’t originate from any biological or plant-based sources, unlike cotton or wool. It was one of the first synthetic fibers to be mass-produced.

3.4. Is nylon biodegradable?

No. One of the major disadvantages of nylon is its resistance to natural decomposition. In landfills, nylon can persist for decades—contributing to plastic pollution. Some research is being done on biodegradable alternatives and enzymatic breakdown, but they are not yet widespread.

3.5. Is nylon toxic?

In daily use, nylon is not considered toxic. However, during manufacturing or incineration, it can release harmful byproducts like formaldehyde or nitrous oxide. In terms of skin contact, nylon may cause irritation in some sensitive individuals, especially when worn tightly or for prolonged periods.

3.6. Is nylon flammable?

Yes, nylon is flammable, though its ignition temperature is higher than some other plastics. When ignited, it burns with a bluish flame and may drip molten material, which could cause further fire hazards.

To mitigate this, manufacturers often add flame-retardant additives to nylon, especially in applications like electrical components, automotive parts, and construction materials. While treated nylon can meet UL94 flame rating standards (like V-0 or V-2), untreated nylon is best kept away from high-heat or open-flame environments.

3.7. Can nylon be recycled?

Technically, yes, nylon is recyclable. However, its recycling process is more complex and less widely available compared to materials like PET or HDPE.

There are two primary methods of recycling nylon:

- Mechanical recycling: Grinding used nylon into granules for reuse in low-grade applications.

- Chemical recycling: Depolymerizing nylon back into monomers and repolymerizing into virgin-quality material (e.g., Econyl® from nylon 6).

Recycling nylon helps reduce reliance on fossil fuels and cuts down landfill waste, but it requires clean feedstock and advanced facilities—which remain limited globally.

3.8. Does nylon resist UV radiation?

Standard nylon is not UV-stable and tends to degrade when exposed to sunlight over time. Signs of degradation include:

- Yellowing or discoloration

- Brittleness and cracking

- Reduced tensile strength

To solve this, UV stabilizers or coatings (like carbon black or HALS—Hindered Amine Light Stabilizers) are used during production. For outdoor applications—such as nylon zip ties, outdoor furniture, or automotive trims—always opt for UV-stabilized nylon.

3.9. Is nylon electrically conductive?

No, nylon is a natural insulator, meaning it does not conduct electricity. This makes it useful in:

- Wire insulation

- Electrical housings

- Circuit board holders

However, if electrical conductivity is needed (e.g., anti-static applications or EMI shielding), nylon can be modified with conductive fillers like carbon black or metal powders to create conductive nylon composites.

3.10. Can nylon be injection molded?

Absolutely. Nylon is one of the most commonly used engineering plastics in injection molding. It offers:

- Good flow properties

- Dimensional accuracy

- Strong mechanical performance

Due to its strength, wear resistance, and ease of molding, nylon is used in making:

- Automotive parts (gears, bushings)

- Consumer electronics casings

- Tool handles

- Electrical connectors

Various grades of nylon—including glass-filled or heat-stabilized versions—can be used depending on the requirements.

4. Summary Table: Nylon Advantages and Disadvantages

| Advantages |

Disadvantages |

| High strength-to-weight ratio |

Absorbs moisture, reducing stability |

| Excellent flexibility and durability |

Prone to UV degradation without treatment |

| Abrasion and chemical resistance |

Non-biodegradable, contributes to pollution |

| Lightweight and easy to mold |

Complex recycling process |

| Cost-effective and widely available |

Can be flammable without additives |

5. EuroPlas – Your Trusted Partner for Nylon and Engineering Plastics

If you're looking for high-performance plastic materials—including premium nylon compounds and functional additives—EuroPlas is the name to trust.

As a global leader in masterbatch and compound solutions, EuroPlas offers a wide portfolio of plastic materials including:

With state-of-the-art manufacturing facilities, expert R&D teams, and an expansive distribution network, EuroPlas is committed to helping customers across packaging, automotive, consumer goods, and electronics industries.

Whether you’re developing a cost-effective nylon-based part, improving product performance, or reducing environmental impact, EuroPlas delivers custom-tailored solutions to match your exact needs.

If you are looking for a suitable additive for your plastic product, don't hesitate to contact our team of consultants today for advice and to receive samples.

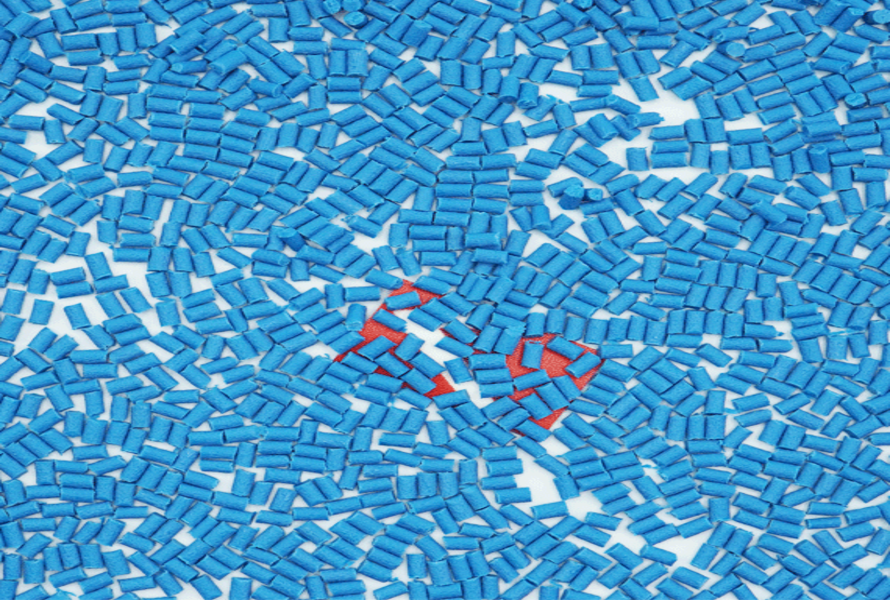

EuroPlas' PA6, PA66 glass fiber compound

6. Frequently Asked Questions (FAQ)

6.1. Is nylon environmentally friendly?

Not inherently. Nylon is petroleum-based and non-biodegradable. However, recycled or bio-based alternatives like Econyl® are helping reduce its environmental footprint.

6.2. Which is better: Nylon or Polyester?

It depends on application. Nylon is generally stronger and more abrasion-resistant, while polyester offers better UV resistance and lower water absorption.

6.3. Can nylon be composted?

No. Nylon doesn’t decompose naturally in compost. Only certified biodegradable plastics (like PLA) are suitable for composting.

6.4. Is nylon safe for food contact?

Some grades of nylon (like Nylon 6) are FDA-approved for food-contact applications, such as cooking utensils and food packaging. Always check with your supplier.

7. Conclusion: Nylon—A Material of Many Faces

From clothing to car engines, nylon's versatility is unmatched. Its combination of strength, flexibility, and affordability makes it an ideal material across industries. Yet, it's equally important to understand its downsides, especially regarding environmental impact and processing limitations.

As innovation in recycling, bio-based alternatives, and additive technologies continues, nylon remains a cornerstone of modern materials science.

Thinking about choosing or replacing nylon in your application? Let EuroPlas help you make the right material decision.