Nylon melting point is what allows nylon to maintain its structural integrity at high temperatures without softening, melting, or degrading

Nylon melting point is an important factor in determining its suitability for a variety of applications. Today, nylon is widely recognized for its high melting point compared to many other common polymers. This makes it suitable for applications that require thermal stability and durability in high temperature environments. In fact, Nylon melting point is what allows nylon to maintain its structural integrity at high temperatures without softening, melting, or degrading. Understanding the nuances of nylon melting point and how it compares to other polymers is key to selecting the right material for your intended tooling applications. The following article will provide a more detailed look at Nylon melting point and its thermal properties!

1. What Is Nylon?

Some typical properties of Nylon are durability, good elasticity, excellent tensile strength, abrasion resistance, chemical resistance and good heat resistance

Nylon is known as the first synthetic polymer made entirely from petrochemicals. The molecular structure of Nylon consists of long chains of repeating units connected by amide bonds (–CONH–). Specifically, the molecular chains of Nylon are created through the condensation polymerization of diamine and dicarboxylic acid. In the market today, the two most well-known types of Nylon are Nylon 6 and Nylon 6,6. The names of each type correspond to the number of carbon atoms in their monomers.

In terms of properties, Nylon is highly appreciated for possessing a series of outstanding properties. Some typical properties of Nylon are durability, good elasticity, excellent tensile strength, abrasion resistance, chemical resistance and good heat resistance. In addition, Nylon plays an important role in many mechanical applications thanks to its much lower coefficient of friction compared to other materials.

Nowadays, Nylon is very popular and widely used in many different industries. Some common applications of Nylon include the production of clothing, knitwear, sportswear, ropes, fishing lines, food packaging, etc. In addition, Nylon is also chosen for many applications in technical industries such as automobiles, mechanics, medicine, etc.

Read more: What is nylon? All about its properties and common uses

2. All About Nylon Melting Point

2.1. Overview of the melting points of popular Nylon types:

Nylon melting point is one of the most important factors that need to be carefully considered before manufacturing products from this material. Nylon melting point is the unit that helps determine the performance of this material in many different temperature environments. In fact, the exact melting point of nylon can vary depending on the initial production rate. Here is all the useful information you need to know about nylon melting point.

Nylon 6: The melting point of this type of nylon is determined to be around 215°C to 220°C (419°F to 428°F).

Nylon 6,6: For this material line, the nylon melting point is considered higher than Nylon 6. The number fluctuates around 255°C to 265°C (491°F to 509°F).

Nylon melting point tends to be higher when the number of more crystalline regions in the polymer structure is higher

2.2. Factors affecting the melting point:

Polymer structure: nylon melting point tends to be higher when the number of more crystalline regions in the polymer structure is higher. In fact, Nylon 6,6 has a more ordered and symmetrical structure than Nylon 6. Therefore, Nylon 6,6 has a higher nylon melting point.

Molecular weight: in addition to the polymer structure, this is also one of the factors that can affect the nylon melting point. In which, the nylon melting point can increase in the case of high molecular weight. The reason is that when the weight increases, it will help increase the stability of the overall polymer, which will also help increase the nylon melting point.

2.3. Suitable application and production

Nylon melting point is one of the factors that need to be carefully considered before deciding on the appropriate production method. Most plastic materials are produced by melting and reshaping. Determining the Nylon melting point helps to choose specific manufacturing methods such as injection molding, extrusion, blow molding, 3D printing, etc.

In addition, the Nylon melting point is also a key factor in determining the performance of the product in different temperature environments. Environments with quite harsh temperature spaces such as some automotive parts, insulation equipment, cooking utensils often require a higher Nylon melting point. When the Nylon melting point is located, it also means ensuring that the material will perform well in the expected temperature conditions.

3. Thermal Properties of Nylon

Nylon melting point is determined at a certain temperature stage the material can change to a softer state

Nylon melting point will be the answer to tell us whether the selected Nylon material is suitable for the operating conditions being targeted or not. To ensure the performance of the product, it is necessary to grasp the following key points about the thermal properties of Nylon:

3.1. Melting point

Nylon 6: This material line has a Nylon melting point of about 215°C to 220°C (419°F to 428°F).

Nylon 6,6: This material line has a Nylon melting point of about 255°C to 265°C (491°F to 509°F). Slightly higher than Nylon 6.

3.2. Glass transition temperature (Tg)

Nylon melting point is determined at a certain temperature stage the material can change to a softer state (soft like rubber). In which:

Nylon 6: When Nylon melting point is about 50°C to 60°C (122°F to 140°F), glass transition may occur.

Nylon 6,6: When Nylon melting point is about 60°C to 70°C (140°F to 158°F), glass transition may occur.

3.3. Thermal conductivity

For Nylon, their thermal conductivity is not highly rated. This makes Nylon a pretty great insulating material. In fact, people use Nylon in some applications that act as insulation such as cooking equipment handles, heat insulation pads, and even some electrical applications.

3.4. Thermal expansion

Nylon is rated to exhibit moderate thermal expansion. When heated, expansion will appear in this material line. Thermal expansion factor in Nylon helps determine the stability of the material in high temperature environments to avoid unwanted damage. The thermal expansion coefficient of Nylon is usually around 80-100 x 10^-6 /°C.

3.5. Thermal deflection temperature (HDT)

The concept of thermal deflection temperature is used to indicate the temperature point at which nylon begins to deform under a specific load. For nylon 6,6, this temperature is usually around 100°C to 150°C (212°F to 302°F). However, this deformation also depends on the material ratio and the reinforcement processing steps during production.

3.6. Decomposition temperature

Nylon melting point is the temperature level that causes the material to melt. But the temperature that causes Nylon to decompose is a much higher number. According to many studies, at temperatures of about 300°C (572°F), Nylon will begin to discolor, lose its mechanical properties, and at higher temperatures, the Polymer structure will be destroyed.

3.7. Fire resistance

Nylon is a material that is considered to have high fire resistance thanks to its relatively high Nylon melting point. However, Nylon can still catch fire in environments that exceed the allowable level. Therefore, some Nylons have been studied to combine additives to increase the Nylon melting point and increase its fire resistance.

4. Applications Where Nylon’s Melting Point Is Critical

Some household materials that can be exposed to high temperatures such as pot handles, pan handles, plastic plates, kitchen appliance insulation, cups, etc

Nylon melting point is considered an important factor in many different applications. Let's take a look at some of the Nylon melting point evaluated in some common applications

4.1. Automotive components

Some applications that Nylon contributes to include coolant tanks, air intake pipes and under-hood components, and some parts that are exposed to high temperature

For automotive engine components, Nylon melting point is always an important factor that needs to be carefully evaluated. Some applications that Nylon contributes to include coolant tanks, air intake pipes and under-hood components, and some parts that are exposed to high temperatures. In addition, nylon gears and bearings operating in automotive machinery with high friction frequencies can generate high temperatures. Careful evaluation of Nylon melting point helps prevent components from softening or deforming during operation.

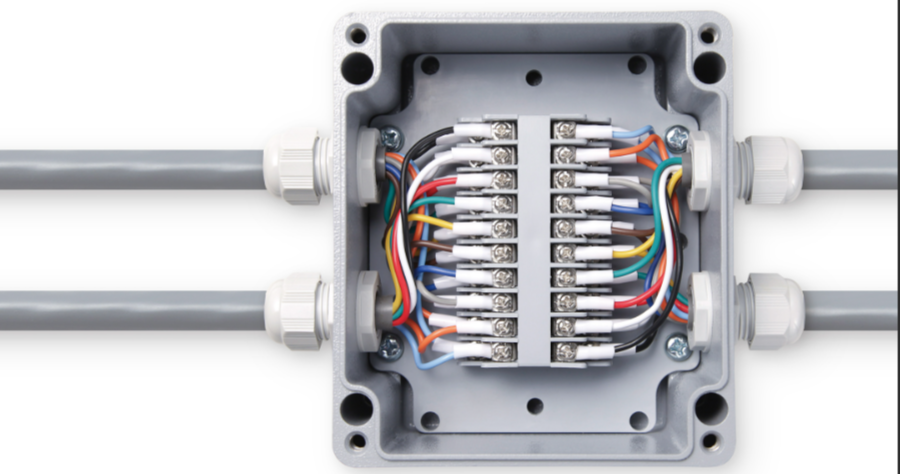

4.2. Electrical and electronic equipment

Some of the applications that Nylon is used for include electrical connectors, cable ties, protective covers, insulation, etc.

Electrical and electronic equipment has a rather complex structure, so ensuring Nylon melting point is extremely essential. Some of the applications that Nylon is used for include electrical connectors, cable ties, protective covers, insulation, etc. When Nylon has a high melting point, it also means that these components maintain their shape and function even in environments near electrical sources or high heat. This is an important factor in ensuring the safety of users.

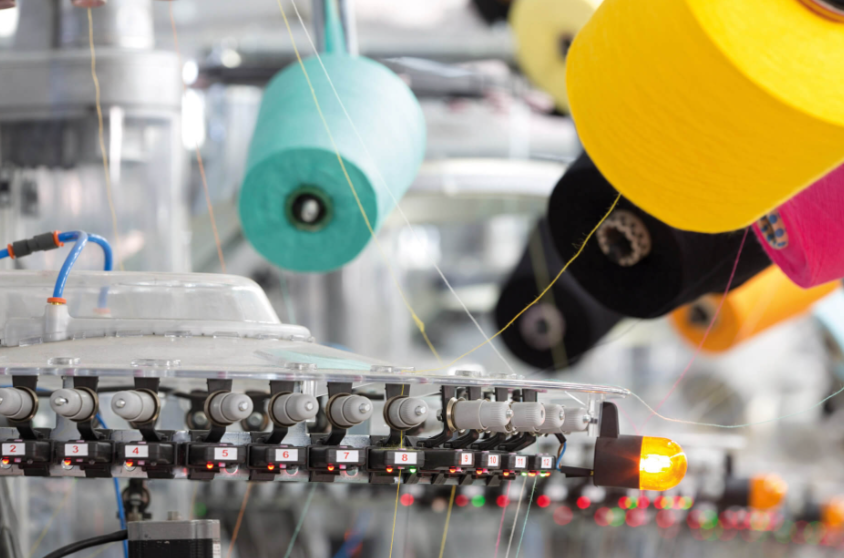

4.3. Textile industry

Some apparel applications require durable performance such as fabrics for outdoor wear, sportswear, and military applications

Nylon melting point is a key factor in the production of high-performance fabrics. Some apparel applications require durable performance such as fabrics for outdoor wear, sportswear, and military applications where the material may be exposed to heat. High Nylon melting point ensures that the fabric can withstand washing, drying, and high ambient temperatures without degrading.

4.4. Aerospace

Nylon is favored in many aircraft machinery parts due to its lightweight, high strength, and good elasticity

Operating in aircraft components is one of the most extreme environments. Nylon is favored in many aircraft machinery parts due to its lightweight, high strength, and good elasticity. At the same time, Nylon melting point can withstand high temperatures in flight conditions.

4.5. Consumer products

Some household materials that can be exposed to high temperatures such as pot handles, pan handles, plastic plates, kitchen appliance insulation, cups, etc

Nylon melting point is strictly required in many diverse consumer applications. Some household materials that can be exposed to high temperatures such as pot handles, pan handles, plastic plates, kitchen appliance insulation, cups, etc. These items need to withstand high temperatures without melting or deforming.

5. Compare Nylon Melting Point with Other Polymers

Understanding the Nylon melting point and its thermal properties is a solid basis for making informed decisions when selecting a material

Polyethylene (PE):For Low Density Polyethylene (LDPE) the melting point is ~105°C to 115°C (221°F to 239°F). For High Density Polyethylene (HDPE) the temperature will fall to ~120°C to 130°C (248°F to 266°F). From this it can be concluded that Polyethylene has a much lower melting point than nylon.

Polypropylene (PP):The melting point of Polypropylene is shown to be ~160°C to 170°C (320°F to 338°F). This shows that PP has a lower melting point than nylon. They are only suitable for medium temperature applications.

Polyvinyl Chloride (PVC): According to research, the melting point of PVC is ~160°C to 210°C (320°F to 410°F). That is, the melting point of PVC is similar to Nylon 6 but generally lower than Nylon 6,6,.

Polystyrene (PS): The melting point of crystalline PS can be up to ~240°C (464°F). From this, it can be seen that this number is close to the melting point of Nylon 6,6,. However, in terms of properties, polystyrene is more brittle and less durable when subjected to heat.

Polycarbonate (PC): According to research, the melting point of PC is ~260°C to 270°C (500°F to 518°F). Polycarbonate has a similar melting point that is sometimes slightly higher than Nylon 6,6, making it great for applications that require transparency and high heat resistance.

Polyethylene Terephthalate (PET): PET also has an impressive melting point of ~250°C to 260°C (482°F to 500°F). It can be seen that the melting point of PET is similar to Nylon 6,6. This material is often used in applications that require a balance between thermal and mechanical properties, such as in beverage bottles and textiles.

6. Conclusion

In conclusion, the melting point of Nylon plays a key role in ensuring their performance and safety in the applications they serve. In particular, Nylon 6,6, ensures that the material can withstand high temperatures without compromising its structural integrity. This makes Nylon an ideal choice for applications in harsh environments. Understanding the Nylon melting point and its thermal properties is a solid basis for making informed decisions when selecting a material.

7. About EuroPlas

We at EuroPlas are a passionate team of innovators, dedicated to providing our customers and partners with the tools they need to succeed in the global marketplace. At EuroPlas, you don’t just get a supplier – you get a trusted advisor with a global perspective and a commitment to your success.

At EuroPlas you can easily find high-quality Nylon 6,6 and synthetic resins for your next project. Visit the EuroPlas blog for a library of articles on various plastics and their applications.

Read more: Nylon 66: What is it? Properties, benefits and applications