Contrary to its negative environmental reputation, plastic plays a surprisingly vital role in the advancement of renewable energy technologies. Often overlooked, plastics offer a unique combination of benefits: lightweight construction, exceptional durability, resistance to corrosion, and superior insulation. These properties make them ideal for crucial components in solar panels, wind turbines, and even energy storage systems. As we strive for a sustainable energy future, this guide delves into the diverse applications of plastics in the renewable energy sector, showcasing their positive contribution to clean energy solutions.

1. Plastic Role In Solar Energy

The solar energy industry greatly benefits from the versatility of plastic materials. Plastic plays a significant role that is involved in everything from the manufacturing of solar panels to energy storage systems. Plastics play a pivotal role in every phase of the solar energy lifecycle.

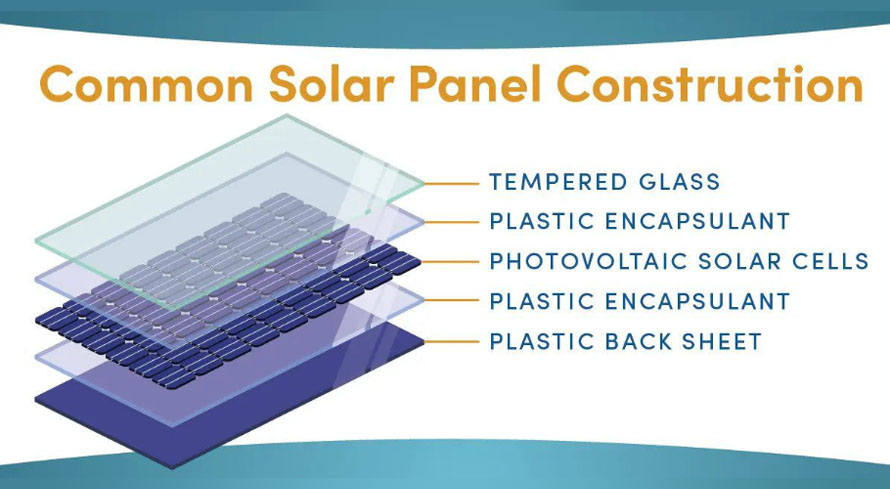

1.1. Solar panels

Solar panels consist of photovoltaic (PV) cells, which harness sunlight to generate electricity. To safeguard these delicate cells from the elements, a clear plastic layer is typically employed. This protective covering allows sunlight to penetrate while shielding the cells from harsh weather conditions like rain, and wind. Plastic's durability and adaptability make it an essential component in solar panel construction, ensuring the longevity and efficiency of these renewable energy systems.

Plastic plays a significant role in every phase of the solar energy lifecycle.

While glass has traditionally been the dominant material for solar panels, innovative plastic technologies offer a viable alternative to replace almost all glass parts with plastic. This substitution results in solar panels that are significantly lighter and easier to install, making them a more practical choice for various roof configurations.

1.2. Casings and Supports for Solar Panels

Plastics are essential in the construction of solar panel casings and supports. These components offer vital protection for the fragile solar cells while keeping them securely in place. By using plastic, the overall weight of the system is reduced, making installation easier, particularly in challenging locations such as rooftops.

1.3. Cables and Connections

Solar energy systems require durable cables and connections for efficient power transmission. Plastics like HDPE and PVC are widely used for their weather resistance and flexibility, ensuring reliable, long-lasting electrical connections in outdoor environments.

1.4. Energy Storage

Beyond power generation, plastics contribute to the storage of solar energy. Rechargeable batteries, designed to store electricity produced by solar panels, frequently feature plastic elements in their casings and internal components.

2. Plastic Role In Wind Energy

Plastics play a vital role in the wind energy sector by enhancing the efficiency and durability of wind turbines. From lightweight turbine blades to corrosion-resistant coatings, plastics contribute to making wind power more sustainable and cost-effective.

Plastics play an essential role in the wind energy industry as they increase the longevity and efficiency of wind turbines.

For example, thermoplastic high-performance plastics provide a comprehensive solution for efficient and powerful wind turbines:

- From onshore to offshore, large to small, these materials offer diverse applications and benefits.

- Their resistance to corrosion, lightweight nature, and recyclability make them superior to traditional materials like aluminum, metal, and copper.

- Their excellent thermal conductivity and high-temperature resistance further enhance their suitability for wind turbine components.

For applications subject to intense mechanical stress, harsh conditions, or extreme temperatures, heavy-duty materials are essential. Glass-fiber and carbon-fiber reinforced plastics are ideal for components like frames, covers, and rotor blades in wind turbines. These advanced materials are praised for their lightweight yet robust nature, providing mechanical properties comparable to metals while ensuring reliable, efficient, and safe operation under high loads.

3. Plastic Role In Bioenergy

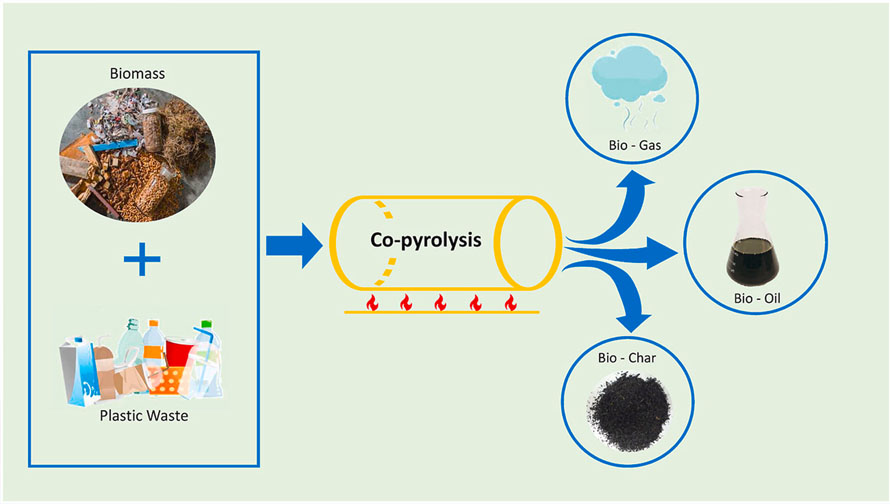

The limited availability of fossil fuels poses a challenge for energy sustainability, as these resources are steadily diminishing. One promising solution is the production of biofuel from biomass and plastic waste.

As fossil fuel resources become increasingly scarce, biofuel production from biomass and plastic waste emerges as a viable alternative for sustainable energy

The transformation of plastic waste into biofuels is a valuable process that transforms waste into fuel through pyrolysis. Pyrolysis, a thermal decomposition technique, is employed to convert waste into fuel. The pyrolysis process involves heating solid waste in the absence of oxygen, resulting in the production of pyrolysis gas and char. The pyrolysis gas contains light hydrocarbon fractions that can be used as fuel or further processed to create eco-fuels. Char, a carbon-rich material, can be utilized as fertilizer or charcoal fuel.

4. Advantages of Using Plastics in Renewable Energy

Plastics offer a range of benefits in renewable energy applications, enhancing both efficiency and sustainability. Their unique properties contribute to the longevity, cost-effectiveness, and adaptability of renewable energy systems, making them a valuable material in this sector.

4.1. Durability and Longevity

Plastics are highly durable and resistant to environmental factors, ensuring long-lasting performance in renewable energy systems. For example, those used in solar panel encapsulants, offer exceptional durability and resistance to environmental factors. EVA (ethylene-vinyl acetate) films protect solar cells from moisture and UV rays, extending their lifespan. This durability reduces the frequency of maintenance and replacement.

4.2. Versatility and Flexibility

Plastics can be molded and shaped into a wide variety of components, making them suitable for various renewable energy technologies. For instance, in solar panels, plastic backsheets provide protection, insulation, and structural support, while plastic encapsulation materials ensure the long-term reliability of the solar cells.

4.3. Lightweight Properties

The lightweight nature of plastics improves the efficiency of renewable energy installations. In applications like wind turbines and solar panels, reducing the overall weight enhances performance. This leads to lower transportation costs and simpler installation processes.

4.4. Cost-Effectiveness

Plastics provide a cost-effective alternative to traditional materials like metals. For example, polypropylene used in photovoltaic panel housings will often be more affordable than metals.

4.5. Resistance to Corrosion

Plastics resist corrosion, making them ideal for use in harsh environmental conditions. They maintain their performance and integrity in applications like offshore wind farms and solar installations.

5. Innovations and Future Trends

As the renewable energy sector continues to evolve, plastics are playing an increasingly vital role in driving innovation and shaping the future of sustainable energy solutions.

5.1. Innovations in Plastics

Plastics, a versatile and adaptable material, are at the forefront of innovation in the renewable energy sector, driving advancements in various components and systems.

- Advanced Plastic Composites: High-performance composites made from plastics and reinforcing materials like carbon fiber or glass fiber are being used in wind turbine blades, solar panel frames, and energy storage systems. These composites offer exceptional strength, durability, and lightweight properties.

- Recycled Plastics: Integrating recycled plastics into renewable energy components is a growing trend. This helps reduce waste, conserve resources, and promote a circular economy.

- Bioplastics: Bioplastics from renewable resources offer eco-friendly alternatives with a lower carbon footprint.

- Advanced Polymer Engineering: Enhanced polymers provide improved strength, flexibility, and durability for specialized applications.

- Smart Plastics: Plastics with sensors react to environmental changes, offering real-time data and functionality.

5.2. Future Trends in Renewable Energy

Looking ahead, several emerging trends in plastics technology offer promising opportunities for innovation and advancement in the renewable energy industry.

- Integration with Solar Technologies: Future plastics will increasingly be designed for seamless integration with solar technologies, including advanced photovoltaic materials and flexible solar panel substrates.

- Enhanced Wind Turbine Components: The development of next-generation polymers will lead to even lighter and more durable wind turbine blades, optimizing energy production and reducing maintenance costs.

- Smart Plastics for Energy Management: Innovations in smart plastics will enable real-time monitoring and optimization of energy systems, improving efficiency and responsiveness in renewable energy applications.

- Recycled Plastics in Energy Systems: The use of recycled plastics will become more prevalent in renewable energy systems, contributing to circular economy practices and reducing the environmental impact of plastic waste.

- Advanced Energy Storage Materials: Future trends will focus on developing new plastic-based materials for energy storage solutions, such as improved batteries and capacitors, to enhance performance and reduce costs in renewable energy systems.

6. Conclusion

To sum up, plastics have emerged as a versatile and essential material in the renewable energy industry. Their properties, such as lightweight, durability, and versatility, make them ideal for various applications, from solar panels and wind turbines to energy storage systems. As the world transitions towards a more sustainable future, plastics will continue to play a pivotal role in driving innovation and ensuring the success of renewable energy technologies.

7. About EuroPlas

EuroPlas, a leading manufacturer of plastic solutions, offers a comprehensive range of filler masterbatches designed to enhance the performance and sustainability of plastic products, particularly in the renewable energy sector. Filler masterbatches are specially formulated blends of polymer resins and various fillers, such as calcium carbonate, talc, BaSO4 that are added to plastic compounds to improve their properties.

- PE filler masterbatch: Reduce production costs by using PE filler masterbatch, as it effectively replaces part of the PE resin with CaCO3 powder. Improve product qualities such as impact resistance, heat resistance, and surface hardness, enhancing the overall durability and flexibility of the final items in the renewable energy sector as solar panel casings and wind turbine parts. Additionally, PE filler masterbatch can reduce the environmental impact by lowering the overall polymer consumption in manufacturing processes, contributing to more sustainable energy solutions

- PP filler masterbatch: Made from polypropylene resin, CaCO3, and additives, reduces production costs while improving the durability and heat resistance of plastic products. In the renewable energy industry, PP filler masterbatch can be used in parts like the casings and housings of solar panels and in the production of non-critical structural components for solar panels. By reducing the amount of virgin resin needed, it offers a cost-effective alternative while maintaining essential properties like rigidity and heat resistance.

- Transparent filler masterbatch: Composed of inorganic powders like Na2SO4 or BaSO4, along with plastic resins such as Polypropylene (PP) or Polyethylene (PE) that enhances the clarity and performance of plastic products. In the renewable energy industry, this filler is used in applications like the outer protective layers of solar panels to protect the panels from wind damage while maintaining light transmission and overall panel efficiency; or nacelle covers for wind turbines to protect internal components while allowing for visual inspection and maintaining some level of light transmission, etc.

- HIPS filler masterbatch: Deliver high whiteness, excellent dispersion, and compatibility with HIPS filler masterbatch due to its high CaCO3 loading. HIPS filler masterbatch helps to improve the strength and durability of renewable energy components, for example in wind turbine housing parts. Apply it to reinforce the structure of blades and casing in wind turbines, where resilience and thermal resistance are crucial.

EuroPlas provides a wide range of filler masterbatches intended to improve the sustainability and performance of plastic products for renewable energy

By utilizing EuroPlas's filler masterbatches, manufacturers can develop more sustainable and efficient plastic solutions for renewable energy applications, such as solar panels, wind turbines, and energy storage systems. These masterbatches contribute to the overall performance, durability, and cost-effectiveness of renewable energy products, helping to drive the transition to a cleaner and greener future.

To learn more about EuroPlas's filler masterbatches and how they can benefit your renewable energy project, please contact us today.